Cabka has developed the CabFold Hybrid from scratch for the storage and dispatch of body and chassis parts in close cooperation with the car manufacturer BMW Group. The foldable large load carrier (GLT) has a recyclate content of 94 per cent and allows the car manufacturer to significantly reduce emissions in packaging logistics.

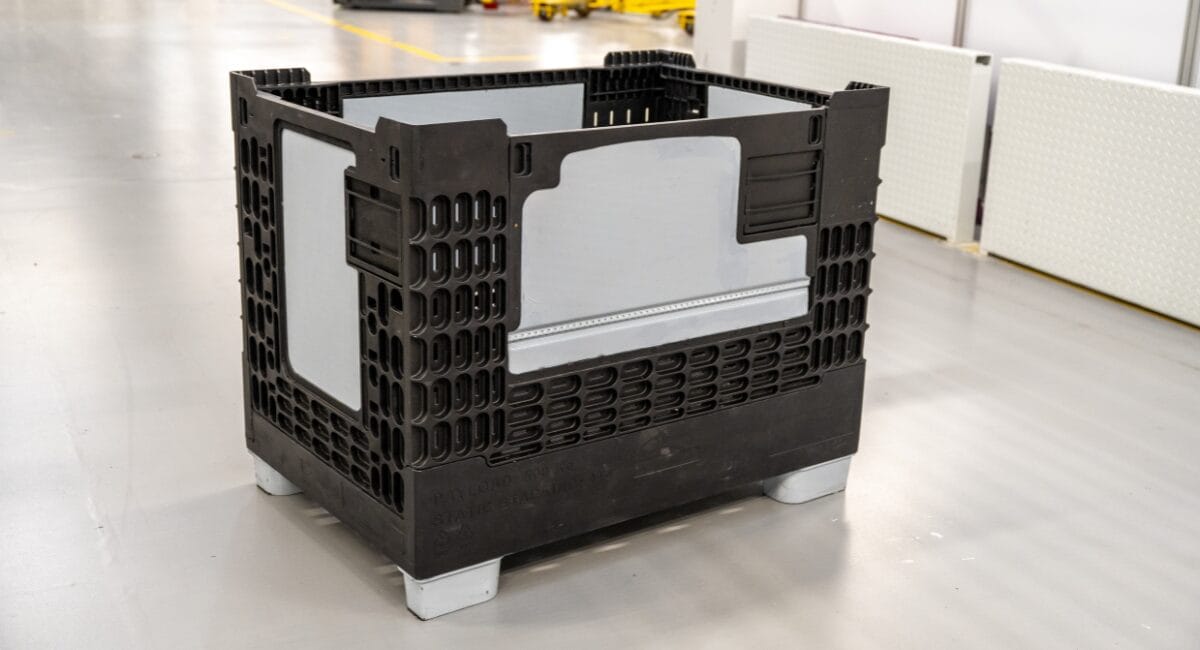

Thanks to its new design, the container offers the largest internal volume in its class at 755 litres - in direct comparison with all other large load carriers on the market that have comparable external dimensions. This means more space for the transported goods and more efficient utilisation of space during transport. BMW can permanently reduce the volume of empties during storage and return transport to less than a third of the previous volume. The car manufacturer thus gains valuable space and can also significantly reduce the number and costs of return transport. 288 folded CabFold Hybrid fit into a lorry.

Seamless integration

The new foldable GLTs made of recycled plastic expand the BMW Group's standard container pool and replace the previously used mesh boxes. Storing these rigid and heavy containers and organising the return transport took up a lot of space and caused high costs. Due to the open design, those responsible often had to use additional disposable cardboard packaging to protect the transported goods from soiling and rust. The large load carrier customised for BMW fits seamlessly into the existing logistics process and makes it significantly more efficient, safer and more sustainable.

„We are proud to have developed such an innovative large load carrier together with the BMW Group. This collaboration also highlights our speciality in the market: we can be both a disposal company for used plastics and a development partner for state-of-the-art load carriers.“

Marius Poppe, Sales Director Customised Solutions at Cabka

Resource-saving, lightweight space miracle

A decisive criterion for both co-operation partners is, that the new CabFold Hybrid fulfils all the important cornerstones of a closed-loop strategyIt consists of 94 per cent recycled plastic, is durable, reusable and can be repaired. Used containers are integrated into the recycling process, allowing users to close the material loop.

With an unladen weight of 52.5 kilograms, the CabFold Hybrid is significantly lighter than comparable large load carriers made of plastic and 40 per cent lighter than the previously used pallet cage. Thanks to its clever design, the CabFold Hybrid Set up and dismantle manually or automatically in just a few seconds - without any predetermined folding sequence. These protect the transported goods from dust and dirt and allow them to be stored outdoors. The smooth surfaces make the CabFold Hybrid easy to clean and minimise the risk of injury.

Source: Cabka