At Fachpack, CETA Testsysteme GmbH and Polman Aimes will be presenting a new inline testing system for leak testing flexible blister packs.

The solution is aimed at sectors such as Pharmaceuticals, food and consumer goods, where the highest standards of product protection and quality assurance apply.

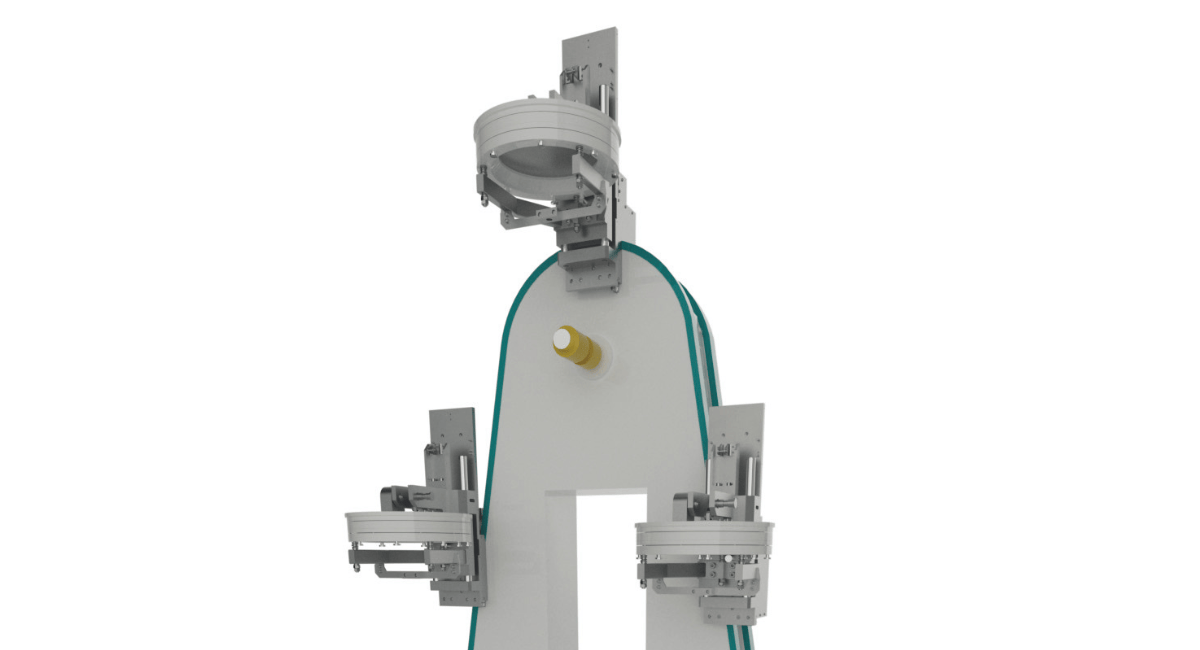

Inline test bench with QLOOP technology

The centrepiece of the trade fair presentation is a space-saving, continuous testing system developed in collaboration with Polman Aimes. It enables the Fully automatic inspection of blister packs with negative pressure and uses specially developed CETA testing devices. These measure possible pressure changes caused by leaks - down to 20 micrometres - at cycle rates of several hundred parts per minute.

Traceability included

The system allows complete traceability of the measurement results through the connection to higher-level control systems. The test pressures between -100 and -800 mbar are generated directly in the devices. This solution combines high testing speed, short cycle times and reliable quality control.

Cooperation between two experts

CETA and Polman Aimes have been working together successfully for many years. While CETA, with over 35 years of experience, specialises in the manufacture of leak and flow testers, Polman Aimes brings its Expertise in industrial robotics and process automation in. Together, they provide practical testing technology for the modern packaging industry.

Source: CETA test systems

CETA Testsysteme GmbH at Fachpack 2025: Hall 7, Stand 7-625