With the increasing acceptance of digital printing in the various application areas of packaging printing, the migration behaviour of ink systems is becoming the focus of packaging printers' decision-making. But what are the differences between the ink systems and for which application segments in packaging and label printing are they particularly suitable?

There is no "one" ink system that meets all applications in digital packaging printing. Printed or labelled packaging must meet other requirements in addition to the demand for minimal migration behaviour and high food safety. In Packaging printing abrasion and scratch resistance, wet strength, light fastness, as well as heat and chemical resistance are equally important criteria that must be taken into account. In addition to migration behaviour must be taken into account. The selection of the colour system used is a key factor in determining which Application segments the printing system and to which segments it can be extended if necessary.

Migration-optimised colour systems in digital printing

The ink systems used in digital printing have a very different structural composition, which also determines their migration potential. The user has the option of choosing between two different digital printing processes and their colour systems The choice is between electrophotography, the dry toner or liquid toner process and inkjet printing.

Dry toner or liquid toner?

The carrier material of the Xeikon dry toner generally consists of over 90 per cent polyester resin. During image transfer in the printing process, the toner particles are electrically charged and fixed to the substrate under the influence of heat at 110 to 130 °C after the powder image has been transferred in the printing zone. The toner particles melt during this process and coagulate to form a homogeneous, solid polyester film with a thickness of approx. 4 µm per toner layer. Due to the large-sized molecules, which are practically immobile in the polyester film, the polyester toner particles can also be called Independent functional barrier consider. For these reasons, the migration risk of dry toner is considered to be negligible.

The carrier material of a liquid toner is a polyethylene resin to which pigments, additives and an oil are added as a solvent. At the start of the liquid toner production process, the resin absorbs some of the solvent, which results in a certain amount of swelling. During the printing process, when it melts onto the substrate, the solvent evaporates from the spaces between the resin particles, whereby solvent that is in the polyethylene resin initially remains there. It takes a certain amount of time for it to complete evaporation of the solvent and swelling of the layer.

For this reason, packaging material printed with liquid toner can be not processed directly from the printing press into packaging if no additional functional barrier is present. After complete evaporation, the risk of solvent migration into the food is low. Due to the resting time, however, there is a disadvantage in the workflow compared to other digital colour systems.

Migration-optimised UV inkjet inks

The formulation of migration-optimised UV inkjet inks consists of a carrier liquid containing highly reactive monomers and diffusion-inhibited photoinitiators. During the drying process under high-energy UV light, the monomers crosslink to form a polymerised ink film.

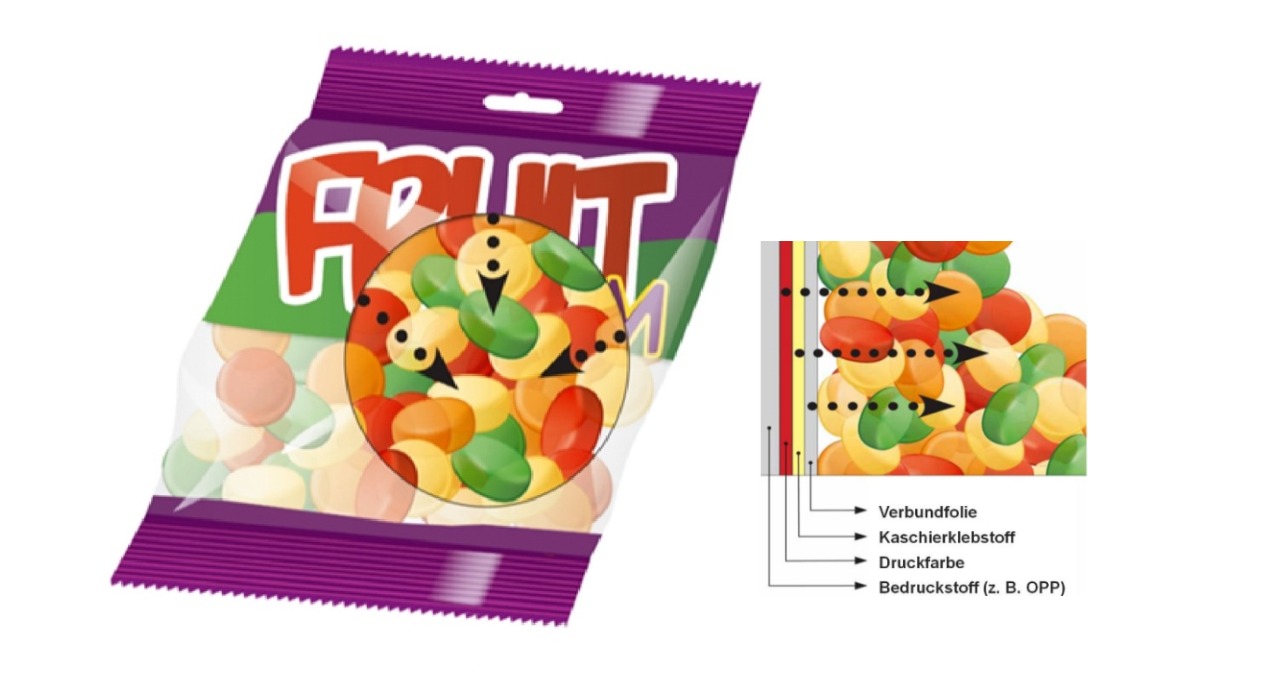

To maximise the degree of cross-linking, it is necessary for the cross-linking to take place in a nitrogen atmosphere, which means that a degree of cross-linking of up to 99.9995 percent can be achieved. This means that the proportion of reactive monomers in the dry colour film is extremely low. On selected substrates, for example PET or very thick PP, it is possible to Food-safe packaging can be realised. Nevertheless, non-crosslinked photoinitiators or monomers can remain in the colour layer and form a Residual risk for migrationwhich in turn can be minimised by a functional barrier. However, laminating this barrier layer requires an additional work step and makes the product more expensive to manufacture.

Solutions for label and packaging printing

How do the properties of the ink systems affect their suitability for use in end-user applications and for which segments is which ink system suitable? The different segments have different requirements for which, in addition to the migration behaviour, the above-mentioned requirements for an ink system must also be met.

"Different applications require different solutions. "With Xeikon's broad digital printing portfolio, there is a suitable solution for every end-user application." David ReiserSales Manager L&P DACH

The application is crucial

If the focus of the portfolio is primarily on the food segment and the other segments of pharmaceuticals, wine & spirits, beverages and health & beauty, the Dry toner process with its clear strength in the Food safety. With a resolution of 1,200 dpi, it fulfils all requirements in terms of print quality and counterfeit protection in the pharmaceutical segment. With machine widths of up to 516 millimetres, it offers a high print volume and, with this print width, is competitive with UV inkjet narrow web machines.

If these segments Authenticity properties If high abrasion and scratch resistance, heat resistance and chemical resistance are required, these properties can be achieved with UV varnishing or film lamination. UV inkjet printing is ideal for high-strength labels, chemical labels, health & beauty or beverages. Its ink system is characterised by high abrasion and scratch resistance, heat resistance, wet strength and resistance to chemicals. Its higher printing speed in the narrow web area is also an advantage. If other segments need to be covered temporarily, for example the food sector, these can be bridged by investing in inert conditions or by laminating barrier films in a separate work step.

Colour systems - Complementary solutions

All of this demonstrates the complementary solutions that dry toner and UV inkjet printing offer in migration-optimised packaging printing. Both colour systems have their strengths and clear application segments. However, they can also be used in a wider range of applications if required. And together they offer a Robust solution portfoliothat meets the needs of demanding end customer markets.

[infotext]This guest article was written by Dr Lode Deprez. He is Vice President Technology Digital Solutions at Xeikon.[/infotext]