Technotrans will be exhibiting cooling and temperature control solutions for digital printing at drupa. The range of thermal management systems extends from compact devices with a minimum cooling capacity of 50 watts to high-performance systems with 50,000 watts and more.

Thanks to capacity-controlled components, the use of natural refrigerants and a high energy density, Technotrans solutions enable users to significantly reduce their CO2-footprint - with high efficiency and productivity at the same time. Digital printers also benefit from maximum flexibility: all systems can be customised to the requirements of the respective printing press become.

„The performance of digital printing presses is constantly increasing - and with it the demands on thermal management. After all, constant thermal parameters are needed to maximise their performance and ensure the quality of results in the long term. We make this possible by supplying cooling and temperature control systems that are precisely customised to the machine requirements for all areas of application.“

Peter Böcker, responsible for the print area at Technotrans.

The fact that the solution expertise of the thermal management specialist has already convinced numerous customers is underlined by this year's drupa. the devices can be seen on several printing machines from well-known manufacturers. Technotrans offers its solutions as integrable systems whose housing is customised to the design of the digital printing machine and as compact add-on units.

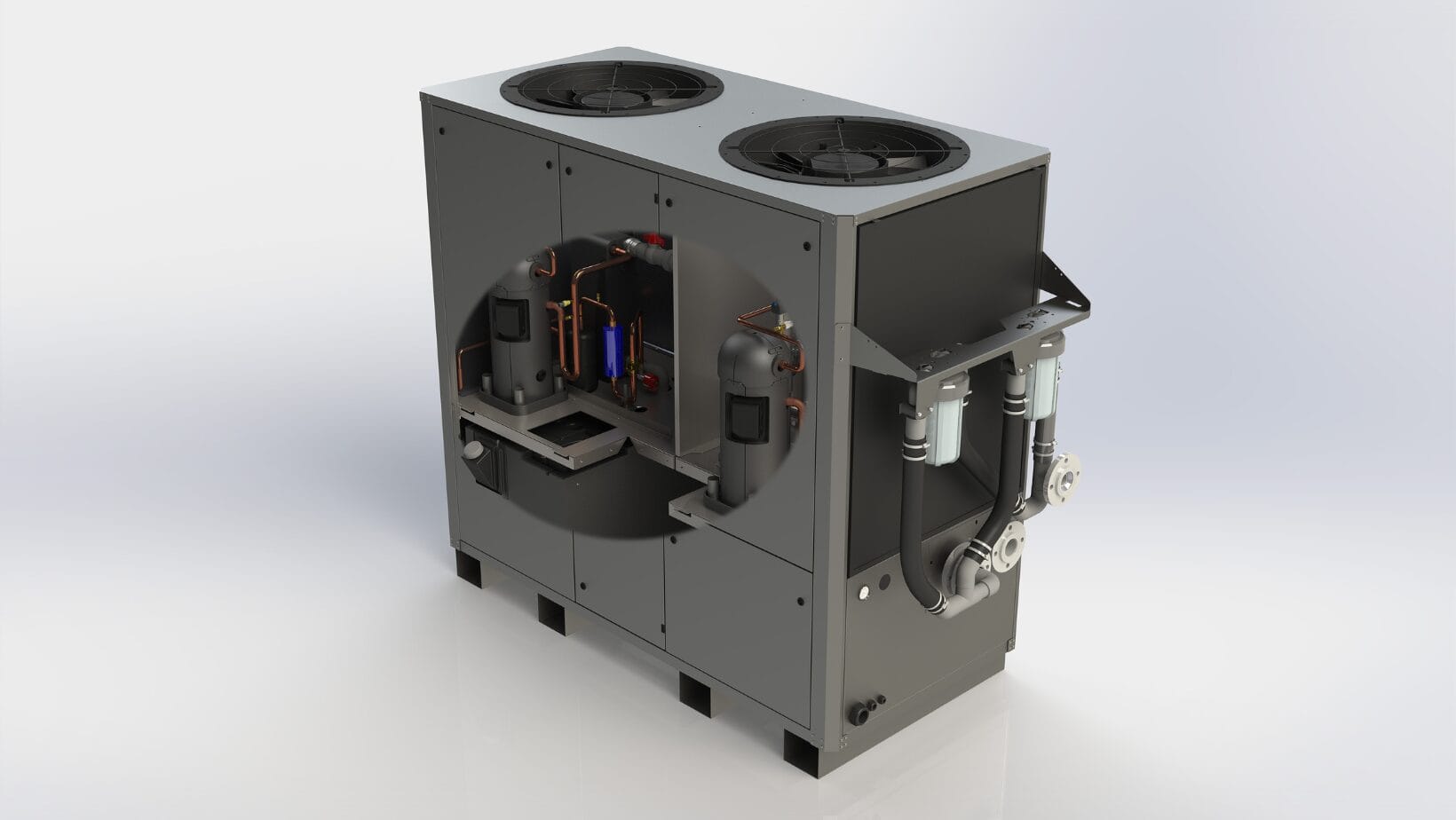

Technotrans will be focussing on the ECOtec.chiller xtend with natural refrigerant R290 at the digital printing trade fair. The low-vibration and quiet-running cooling solution works at all times thanks to power-controlled drives. Energy-efficient with up to 60 per cent less refrigerant used than with conventional solutions. Users reduce their CO2-footprint significantly. At the same time, the compact device is particularly powerful with an energy density of 60 kilowatts per square metre. The modular design of the ECOtec.chiller xtend allows maximum flexibility to customise the device precisely to the requirements of the respective printing press.

High control accuracy, comprehensive service

In the field of compact cooling systems for digital printing, Technotrans is presenting the miko, a particularly small compressor cooling unit with high performance. The 350 x 200 x 330 millimetre mini tower has a high power density with a temperature stability of +/- 0.1 Kelvin. Like all other thermal management solutions from Technotrans, the compact unit is characterised by High control accuracy and user-friendly design out. The cooling systems are available with a communication interface on request. This enables process parameters to be monitored and controlled in dialogue with the digital printing press in order to ensure that it is optimally supplied in every operating state.

Technotrans also pursues a holistic approach to customer care: as a long-standing and internationally active partner to the printing industry, the company has a wide range of expertise at its disposal. A comprehensive service network and thus ensures the availability of its customers„ systems. “Fast response times, high spare parts availability and comprehensive all-round packages are just as much a part of our service offering as the consistent expansion of sustainable digital solutions," emphasises Böcker.

Source: Technotrans

Technotrans at drupa 2024: Hall 1, Stand B10