Beauty begins not only with a newly discovered plant-based active ingredient that reduces wrinkles, but also with a dispenser or bottle whose sustainable production confirms the ecological purchase decision. At CosmeticBusiness in Munich from 5 to 6 June, over 400 suppliers will be presenting trends and developments in the areas of ingredients, manufacturing and packaging.

Sustainability remains the top theme in the packaging sector. This year, exhibitors will primarily be showing how they with monomaterial solutions further facilitate recycling and therefore recyclability. The exhibition also uses various examples to show that recycled materials can be better utilised in the form of PCR.

Eight corners and less weight

Albéa has expanded its EcoTop family. The combined cap-head system is now complemented by the octagonal OctoTop. L'Occitane already uses them for its hand cream tubes, as they correspond to the brand's traditional design. Compared to the previous solution, OctoTop is said to be weight reduced by 21 per cent have. It also reduces the CO2 footprint. The new solution is made from PE and is suitable for recycling in the HDPE stream.

100 per cent PE = 100 per cent recycling

With Mono Micro, Aptar presents its new airless dispenser from the Micro range. It is a certified monomaterial solution, The new bottle is made exclusively from PE, including the cap, container, pump and piston. It is fully recyclable and Cyclos Htp certified. In addition, the airless system enables good residual emptying, is easy to operate from 360° and offers the best possible protection for the contents due to the lack of air recirculation. Mini Micro is manufactured at the Villingen site in southern Germany.

Product portfolio made from just one material

In Munich, Corpack is presenting its mono-material packaging for lipstick, mascara and powder. All components consist of Made from 100 per cent polypropylene (PP). The packaging manufacturer is thus supporting its customers in the development of sustainable products with which they can meet both consumer demand and possible future requirements. Packaging made from just one material is easier to separate and sort, which increases its recyclability. High-quality recyclates can thus be fed back into the production cycle.

Lightweight and monomaterial in one

EPL will also be presenting a mono-material solution at the trade fair. In the flip-top version of the Tiara Ring closure, the manufacturer combines the concept with its Platina laminate product range. The lightweight fastener also saves on materials, which is both ecological and cost-efficient, according to the company. The shoulder-free flip-top fastener enables the use of 360° NEOSeam printing technology, meaning Seamless all-round printing. The initial focus will be on the 50 mm diameter. According to the exhibitor, this is intended to achieve the best possible weight saving.

PCR for coloured flip-top closures

KM Packaging is focussing on recycled material. The manufacturer is presenting its Tango and Melody Ultra flip-top closures, which it is now also producing from PCR material. According to its own information, the company uses a special PCR material with high transparency and thus enables the production of different coloured caps. The proportion of PCR is 70 per cent. According to the manufacturer, the performance of the flip-top cap material is in no way inferior to the quality of virgin plastics.

How plastics become granite and silver

The German masterbatch supplier Lifocolor is presenting two new colour effects from its portfolio. The Masterbatches for granite effect create an authentic stone look on PE, PP, ABS, PMMA and TPE. They are available in various shades and fulfil EU and FDA specifications for food contact, according to the company. They can be used for injection moulding and extrusion processes at up to 280 degrees Celsius. With its new silver and metallic masterbatches Lifocolor's main aim is to enable the recycling-orientated design of cosmetics packaging. The silver colours are to be correctly identified in the sorting system using near-infrared (NIR) and fed into the recycling process.

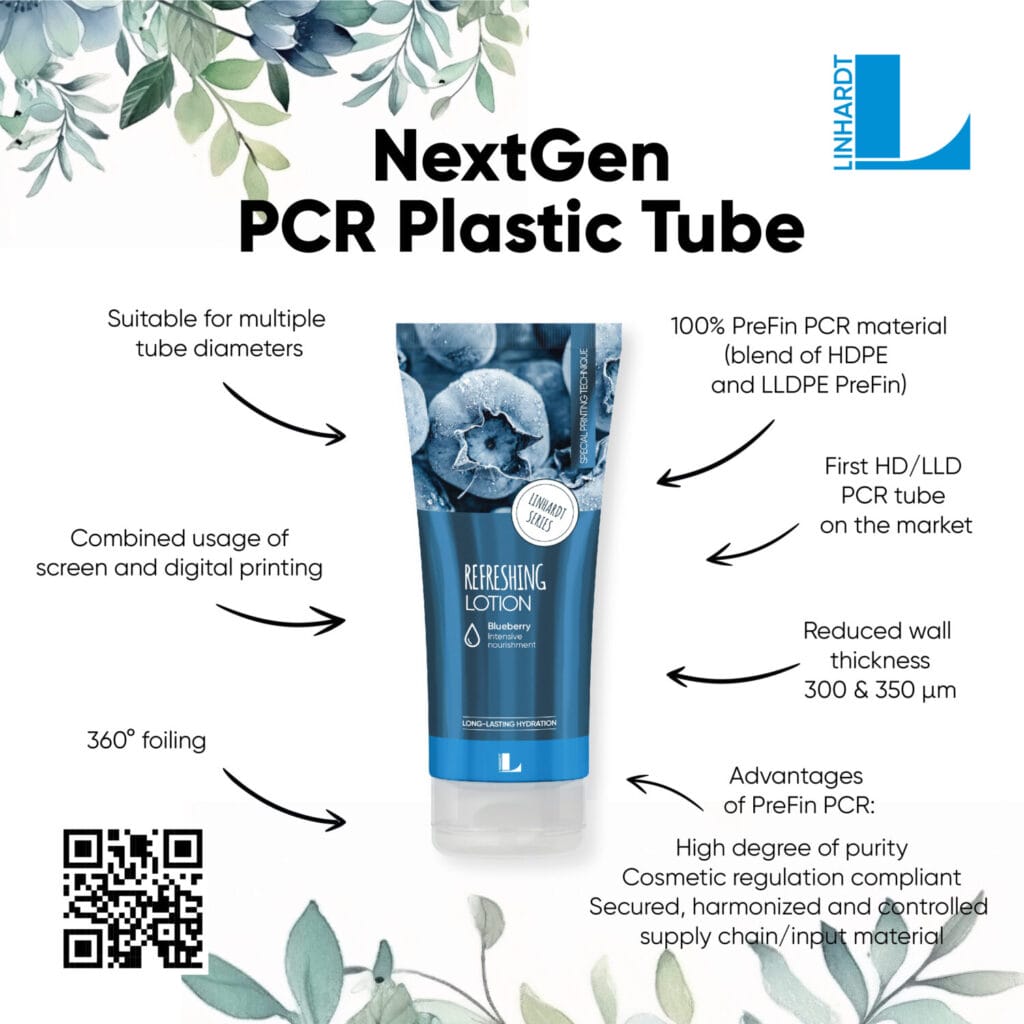

Next generation PCR tubes

Linhardt describes itself as a pioneer in the use of PCR plastics in tubes. This year, the company is presenting its NextGen PCR Plastic Tube. It is therefore the first tube of HD and LLD PCR. It is made from a mixture of rigid and flexible PE, which consists of 100 per cent cosmetics-grade PreFin PCR. According to the manufacturer, this has a high degree of purity and comes from a safe, controlled supply chain. The tubes can be customised using screen and digital printing as well as 360° foiling.

Bio-based packaging designs - as versatile as nature itself

The Japanese company Nissha presents a new 50-ml round jar for water-based cosmetics. It is made from the biobased and industrially compostable material Sulapac. It is available in different colours and different material variants, each based on different natural fabrics. This allows the look and feel to be customised for different brand designs. For example, while a natural look with visible wood shavings conveys the message of natural cosmetics, the clay-based version gives the consumer a luxurious impression, according to the manufacturer.

The stick content becomes the extended brand design

Quadpack is presenting its ShapeUp Stick at the trade fair. The innovative packaging shape makes it possible to Beauty products are dispensed from the dispenser in a personalised, predefined form. A logo, emoticon or other graphic design is cut out at the top. This moulded opening gives the product the shape of a rose, a smiley face or an iconic logo when dispensed. The stick has a capacity of 12.5 ml. It is Easy to refill, recyclable and made from the mono-material PP. The cap and base are made of PCR PP, according to the manufacturer.

New container for the „zerooo“ reusable cosmetics system“

The start-up SeaMe presents its new PET mono-material bottle „designed for Reuse and Recycle“. It will be available from the middle of the year as part of the „zerooo“ reusable system for cosmetics and drugstores operated by the start-up. In the In a closed pooling system, standardised containers from several brands are used. The young company says it wants to prove that „zero waste“ is suitable for the mass market. The reusable system comprises a take-back structure with retail partners, a return and cleaning service, as well as communication including life cycle assessment, serialisation & tracking (GRAI) and deposit handling.

Without air, but with 100 per cent paper

The company Tianshi presents its airless dispenser rebo Paper. It is made entirely of paper. According to the manufacturer, it is suitable for use with a wide range of cosmetics, personal care and pharmaceutical products. The environmentally friendly concept combines the advantages of airless technology, which include a high level of product protection and ease of use, with those of customisation. According to the manufacturer, the dispenser can be with hot foil and other embossing. The dispenser can be refilled with PCR cartridges.

Aluminium tube for refilling

Packaging manufacturer Tubex is presenting its latest development, MonoRefill, in Munich. According to the company, the refill packaging consists of 100 percent recycled aluminium, 95 percent of which is PCR material. The lightweight tube is easy to recycle. The tube is available in different sizes and is designed for refilling perfume bottles and various types of jars and vials.

Source: Leipziger Messe GmbH