At Kühne + Nagel (NL), returned beer crates and plastic boxes were only counted in the supermarket branches. This has now changed. A detection and sorting system from the inspection technology specialist Indspect from Neuwied plays a key role in this. Up to 15,000 trolleys with around 400,000 transport boxes have to be reliably recognised every day.

Kuehne + Nagel is an international logistics and goods transport company headquartered in Switzerland. The company has 22 branches in the Netherlands, four of which are specifically dedicated to one of the country's largest supermarket chains with almost 1,000 locations. Every day, fresh deliveries are made to these branches and empty transport boxes and returns are collected. The Returns end up in the four large Kuehne + Nagel warehouses. For many years, the company relied on the figures provided by the retailers.

Up to 15,000 trolleys per day

Bart Timmermans was the manager of the entire project, which took almost ten years from the initial idea to completion. „In our warehouse in Tilburg, for example, up to 300 large trucks arrive every day from retail outlets in the region. These up to 15,000 different trolleys are filled with empty PET bottles, empty beer crates, plastic film and packaging, products from expired promotions and, above all, a large number of black, blue and green transport boxes,“ explains the project manager. These transport containers contained, for example, meat, sausage and cheese, fruit and vegetables, but also toys.

Nobody knew the exact figures

„Over the years, we at Kuehne + Nagel and the headquarters of the retail chain relied on the documents from the branches. The pledged boxes were only randomly manually counted. We found that there were always discrepancies. If you look at the total quantity, even small differences add up to a considerable amount,“ explains Bart Timmermans. This gave rise to the idea of automatic counting, the results of which have been visible since day one. A second aspect was that the retail centre never knew for sure, How many containers are located in which branch. In order to avoid delivery problems, new boxes were regularly purchased.

99.98 per cent reliability even without an identification mark

The problems with automatically counting the boxes lie in the large volume, the high speed and the fact that none of the boxes have a barcode, QR code or other identifier that would allow them to be easily recognised. „We looked for a partner who only works with visual systems can recognise and count our boxes reliably, i.e. with a rate of over 99 percent. After a long search, we came across Indspect from Germany, which together with our partners Elten from the Netherlands, who are responsible for the transport of the Rollies and Dollies, and Intrion from Belgium, who are responsible for the technical coordination of the many different aspects of the project. It took a few years for everything to fall into place, but now it works perfectly at the four sites in Tilburg, Zwolle, Zaandam and Pijnacker,“ summarises Bart Timmermans.

Reliable detection of up to 400,000 boxes per day

Counting the black, blue and green transport boxes on the trolleys is difficult. There are low and high variants, many are rigid, the foldable ones come completely unfolded or folded, as well as partially folded. Some types also have lids. This results in a total of 24 different boxes in 37 different variants - This means a huge number of differentiations that the system has to recognise. Only around half of the boxes are stacked neatly on their roll containers and are easy to detect despite the lack of barcodes or other identification marks.

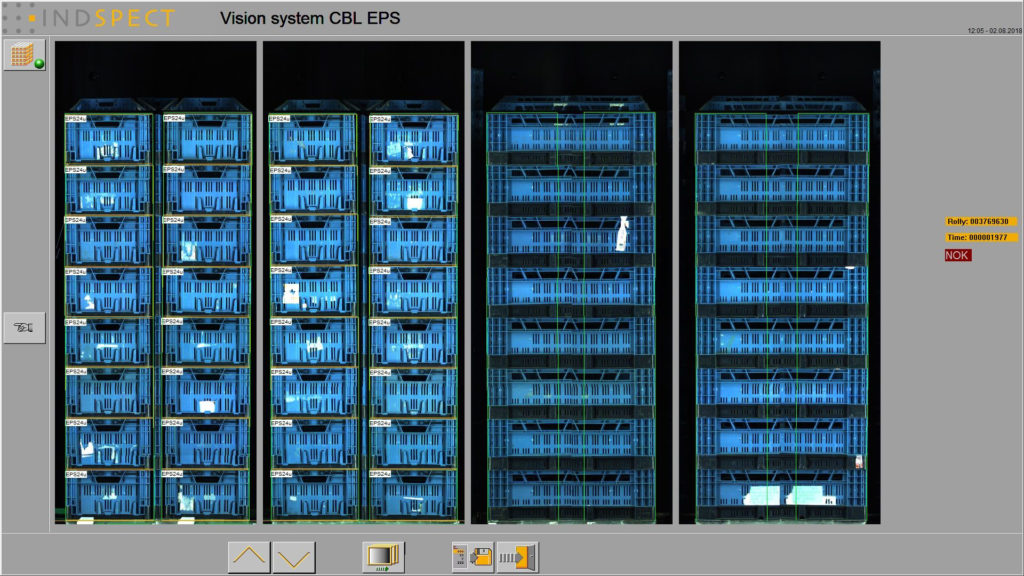

28 cameras recognise all boxes

Indspect supplied a system for the detection of up to 1,000 trolleys (rollies or dollies) per hour, consisting of a total of 28 high-performance CMOS cameras consists of. The manually separated trolleys travel between two transport rails through the entire system. Initially, the trolleys are in transverse motion. Without stopping, a yellow label attached to the stack of boxes with a safety cord is scanned into an identification sheet. This contains all the data for the respective branch, so after scanning, all the boxes on this trolley are clearly assigned to a branch.

Seven cameras are arranged to the right and left of the trolley, which count the boxes as they pass under several LED flashes. For safety reasons, the direction of travel of the trolley is changed so that it passes 14 cameras again when travelling lengthways. This creates a three-dimensional overall image from 56 individual images of each trolley, which is immediately displayed on the monitor.

The number and types of transport boxes on the respective trolley are entered in the Sorting system fed in. Once the securing cord has been removed manually, the unmixed trolleys travel to a lane designated for the respective box type, where they are unloaded by robots, separated, washed and palletised again. In contrast, trolleys with mixed boxes travel to a special lane. There, the containers are manually separated and distributed to various roller conveyors.

Perfect overview and accurate billing

Every four seconds, the Indspect system recognises a trolley with an accuracy of 99.98 percent, registering exactly how many and which boxes are on it. This means that the retailer's distribution centre also knows how many boxes have come back from which branch and how many are in circulation. For the shops, the system means Exact calculation of the deposit, „... which is why they are now very satisfied. They were sceptical at the beginning because they were afraid they would give up too much control. We are highly satisfied with the system and the performance of our partners Indspect, Elten and Intrion,“ emphasises Timmermans.

[infotext icon]The team of specialists at „Indspect “ from Neuwied near Koblenz has been developing and building inspection systems for almost 20 years. The focus is on bottling in the beverage industry. „However, we also use our systems in numerous other sectors of industry in which a 100 per cent control must be achieved,“ explains Indspect Sales Manager Michael Köppen.