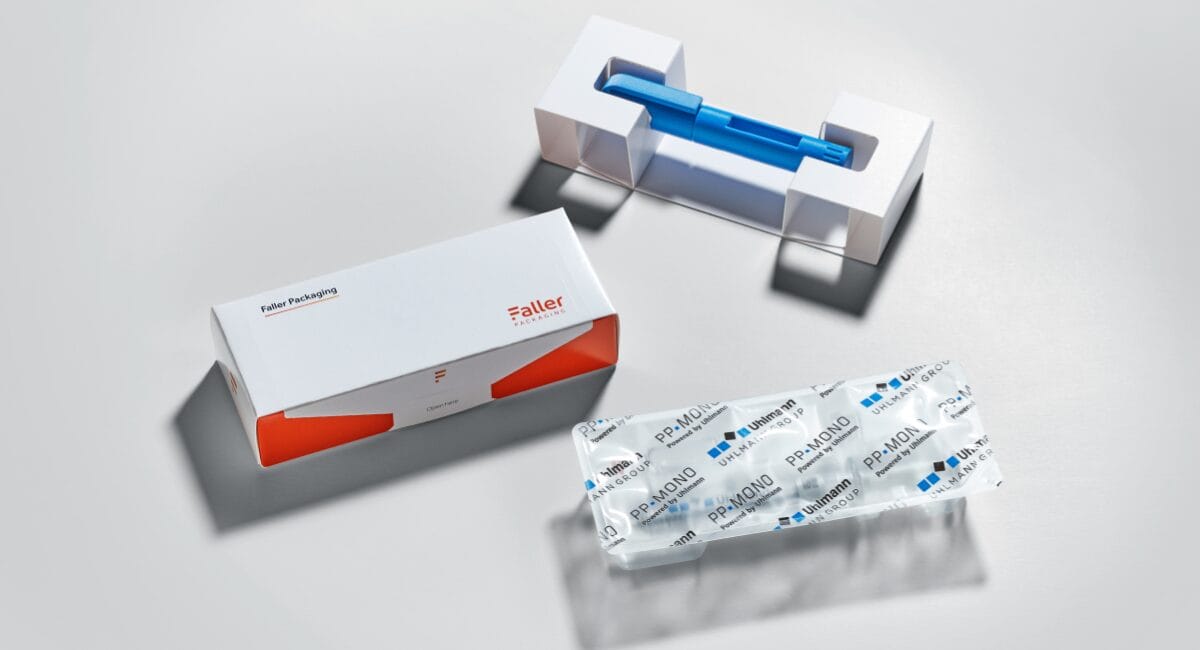

Increasing self-medication with auto-injectors and pens places new demands on secondary pharmaceutical packaging. Faller Packaging is responding to this with sustainable, customisable solutions that combine protection, functionality and user-friendliness.

New active ingredients for weight reduction mark a turning point in obesity therapy. They can be conveniently administered using auto-injectors or pens, even in weekly doses. This lowers the hurdle for patients and encourages the trend of injecting the medication themselves at home. Manufacturers therefore need to rethink not only the content, but also the packagingBreak resistance, intuitive handling, space-saving formats and sustainable materials are becoming increasingly important.

„Standard packaging often reaches its limits, especially for devices such as syringes. Our customised designs combine format, protection requirements and user needs.“

Benjamin Rist, Product Manager at Faller Packaging

The requirements are high: for pens or syringes, but also for sets with vials, ampoules or accessories, solutions are needed that offer more than just protection. The packaging should can be easily integrated into existing production lines without losing sight of user convenience. „This can only be achieved with a customised design that is precisely tailored to the product, process and regulatory requirements,“ adds Rist.

Customisable inlays made from a variety of materials play a central role here. plastic-free, recyclable materials such as fibre-based monomaterials or fibre moulding. Depending on requirements, individual packaging or multipacks can be realised.

In Cooperation with Uhlmann Pac-Systeme packaging solutions that are specially designed for parenteral products. These include the PTC 200 line. It enables the flexible processing of paper and plastic trays and their packaging in folding cartons - while at the same time ensuring the safe and gentle handling of sensitive medicines such as pens, vials, ampoules or syringes.

In addition, Faller Packaging supports pharmaceutical companies with a PrePackaging service that provides flexible, manually loadable packaging units for early market launch phases. The aim is to shorten development times and make processes more efficient.

Source: Faller Packaging