Packaging machine manufacturers are increasingly demanding integrated solutions with fieldbuses for ever higher data throughputs in order to meet the complexity and demand for constantly improving performance. Servotecnica offers customised fluid, fibre optic and hybrid rotary feedthroughs for this purpose.

In automatic machines, such as those used in the Packaging industry Combined rotary transfer units are of great importance in applications where the power transmission is used. They guarantee efficiency and reliability in hard-to-reach places. Slip rings and combined rotary transmitters have been a central part of the Servotecnica range for more than 30 years. The product catalogue includes a wide range of standard solutions as well as products that can be customised. Individual customer wishes and are highly recognised on the market thanks to the company's in-depth technical expertise.

Increasing demand for hybrid rotary feedthroughs

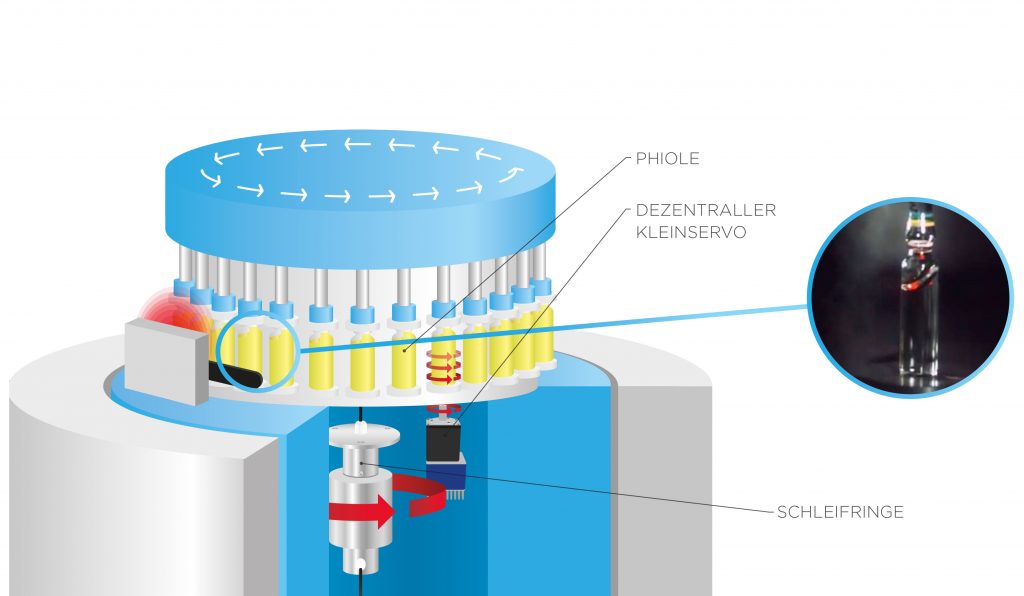

Combined rotary joints are used when different media, such as electricity, electrical or optical signals and liquids, need to be transferred from a fixed structure to a continuously rotating structure. The demand for hybrid rotary unions is increasing. "The need for combined slip rings that combine fluid and electrical parts is constantly increasing," explains Matteo Salgarello, Product Manager for rotary joints at Servotecnica. "The user wants a product that fulfils all the requirements for the rotating part of the machine."

This requirement also results from the cross-industry need to minimise the footprint of the machines without reducing their throughput. "And we are actually witnessing the transition from inline machines to machines with one or more carousels, where rotary transfer units are playing an increasingly important role in the efficiency of the new generation of machines," adds the expert.

In the field of rotary transmitters, there is an increasing demand for products that involve integrated solutions, in particular combined electrical and fluid rotary transmitters with fieldbuses. These products require the utmost care during the planning and development phase in order to avoid interference and noise coupling within the machine. In the packaging industry in particular, the Trend towards hybrid cables increasingly observed.

In almost all cases, slip rings are located in inaccessible places in a machine. It is therefore essential for designers to install a reliable component in order to prevent long machine downtimes due to malfunctions. To ensure this reliability, Servotecnica relies both on its experience and on the intensive manual and automatic testing of all rotary transmitters and their complete traceability.

Optimised products thanks to close cooperation

Combined rotary transmitters are often developed on a customised basis for specific individual applications. "It is therefore very important to us to build a partnership with our customers. The quality of our products is recognised on the market," emphasises Matteo Salgarello. "We advise our customers as early as the machine planning and development phase. This enables us to recommend the best possible rotary transfer unit in terms of customer requirements, performance and costs at an early stage. This increases confidence in our products."

Every order presents the designers with different challenges. With many years of experience and engineering expertise, Servotecnica meets all expectations when developing customised solutions. The electrical part of the rotary transmitters is manufactured by the company, while fluid components are supplied by Dynamic Sealing Technologies and glass fibre components by the specialist Princetel.

Customer-specific individualisation

However, the consultation does not end after the planning and development phase. Servotecnica is also a reliable partner during prototyping or machine set-up. This enables the experts to resolve potential problems and critical conditions during the test phase. For the initial test phase of a customer-specific enquiry, a Standard product as a sample delivered. This determines all the information required for the customised design. On this basis, throughput times can be minimised.

It is becoming increasingly important for machine manufacturers to obtain combined rotary transmitters in the shortest possible time. "This is a major challenge for us, as these are products with a high degree of customer-specific individualisation," says Sagarello. Thanks to its combined expertise and know-how, Servotecnica is able to deliver effective solutions quickly.

"Servotecnica stands for economical products with the highest quality standards. A team of around 50 experienced engineers and experts is on hand to provide customised, cost-optimised solutions for every task," emphasises Christian Becker, Managing Director of SERVOTECNICA GmbH, Raunheim.

Example: Rotary heat exchanger for a detergent filling system

Servotecnica prioritises close cooperation with the customer. This was also the case for a manufacturer of a filling system for cleaning agents. Carousel machines are used when the filling process has to be carried out quickly. For this, Servotecnica supplied a Customised fluid feed-through. "Our customer involved us right from the planning and development phase," explains Matteo Salgarello. "This ensured that we were informed about all individual project requirements."

The specially manufactured rotary heat exchanger is used in a demanding environment that is characterised by the combination of a high degree of sterilisation and the passage of highly aggressive liquids. In view of these different requirements, particular attention had to be paid to the chemical compatibility of the materials used, specifically the metal part and the polymer layer.

"When it came to selecting the right material," explains Matteo Salgarello, "our experience in this area was crucial, as we had to assess the behaviour of the materials during operation and not just under static conditions."

The large dimensions of the machine also had to be taken into account and at least four inputs and almost 100 outputs had to be controlled. "Once we had all the necessary information, we started the design process and offered various solutions until we found the ideal design for the machine. 'the heart of the filling machine' had found."

Servotecnica supplied a large-format (0.5 x 0.5 metres) fluid feedthrough made entirely of AISI 316 steel, into which highly specialised inlet channels were integrated. This results in a significant reduction in overall dimensions and weight. The rotary union supplied guarantees the system manufacturer maximum reliability, which is crucial as maintenance of the rotary union is very difficult due to its difficult-to-access position inside the system after installation.

[infotext icon]Servotecnica was founded as a family business in Milan and has made an excellent name for itself as a partner in mechanical engineering over the past 30 years. The company's slip rings and mechatronic drive products, which are optimised for automation, are used in robotics as well as in packaging machines, for example. In addition to its own subsidiary in Raunheim, the company works with qualified sales partners in all German-speaking countries to ensure intensive application support and excellent local service.