The Swiss mechanical engineering company Kern launched its PackOnTime 2box multi-format packaging system at the beginning of 2020. The first customers are now using it to produce customised outer packaging for online retail. Adhesive application plays a key role in this packaging system.

Photo: Kern

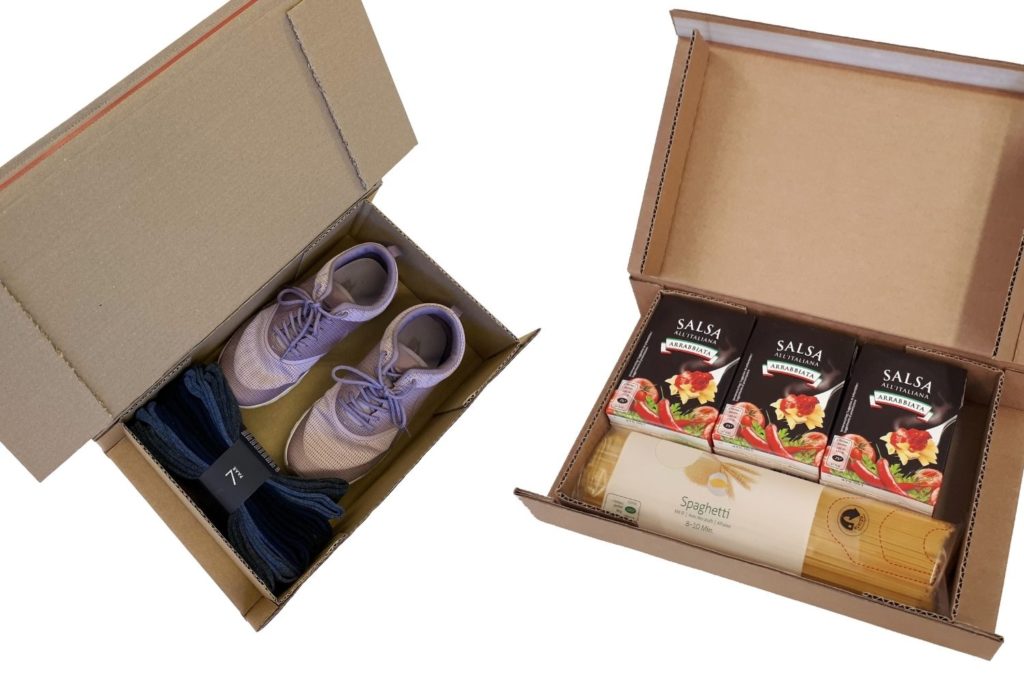

Who hasn't experienced it? The postman brings the long-awaited parcel containing an item you ordered online, but the shipping packaging is huge. Then comes the surprise: the parcel is mainly filled with padding material. The ordered product itself takes up the least amount of space.

"With PackOnTime 2box these shipping packages, which make little sense from an economic and ecological point of view, are now a thing of the past for our first customers," says Patrick Vogel, project manager for the innovative multi-format packaging system at the Swiss mechanical engineering company Kern AG.

Three systems are currently in operation, two at large online print shops and one at an e-commerce provider that packages products from two online shops.

Customised production for all products

While conventional shipping cartons are generally produced in large quantities in standard sizes using inline machines for cost reasons, standard boxes are produced in large quantities in standard sizes.cuts PackOnTime 2box cuts each sheet of corrugated board to the required size. The cut sheets are then erected, glued and transported to the inserting station. After inserting one or more items - which can also be vouchers or advertising for cross-selling campaigns, for example - the sheets are then glued together. the system closes and glues the packaging automatically. Before the parcels leave the system, it applies the shipping labels.

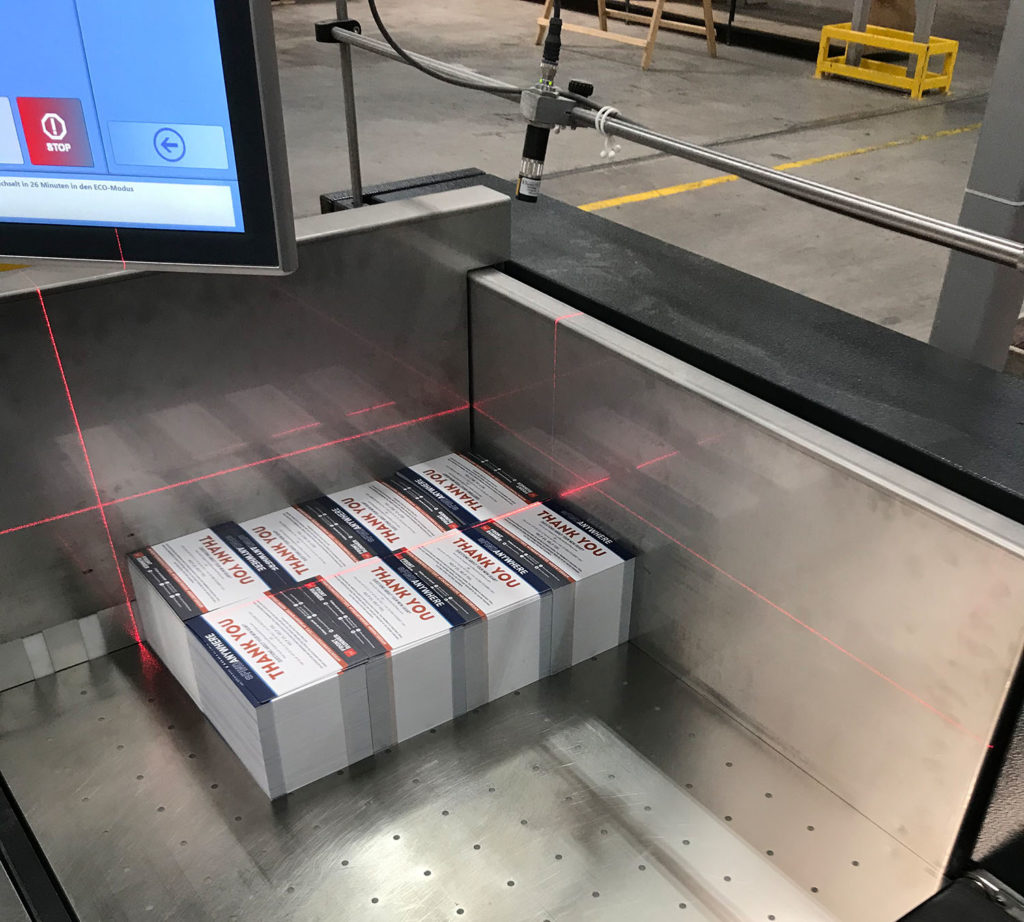

Each individual pack is therefore customised according to the dimensions of the items to be shipped. To do this, the system automatically measures the products to be packaged in three dimensions. As a result, the boxes are barely larger than the packaged goods. "PackOnTime 2box handles the products to be dispatched particularly gently. In addition, the erected cartons are inherently stable even when empty. We have focussed on high packaging quality right from the start," says Vogel, differentiating the innovative system from the wrap-around solutions of the competition.

With the Swiss Packaging Award 2019 and the "Best Product 2020" award in the Identification, Packaging and Loading Technology, Load Securing category at LogiMAT 2020, it has already won two prizes.

Customised bonding with hot glue

Adhesive application plays a key role in the multi-format packaging system. In order to guarantee the stability of the packaging throughout the entire logistics chain right up to the consumer, all components must work together perfectly in the adhesive application. "The topic of hot melt application was new territory for us at the time. Baumer hhs was at our side right from the start with his practical expertise in optimising the hot melt application," Vogel looks back. Which hot melt is best suited for this application? At what temperature do we achieve the best results with the hot melt adhesive? Which adhesive application patterns for which packaging sizes guarantee perfect durability of the bonds while minimising adhesive consumption? "There were many detailed questions that we had to answer together with Baumer hhs," continues project manager Vogel. "The company was and is an important strategic partner for us."

The tesla hot melt valves support the efficient production of high-quality e-commerce packaging.

Above all, the technical concept of the hot melt valves in the tesla family from Baumer hhs was a decisive factor for Kern. "These electromagnetically driven valves are extremely compact. In every PackOnTime 2box-system uses a total of eleven tesla valves, each of which is mounted on linear axes. The compactness of the valves brings advantages for controlling the movements of these linear axes," explains the expert.

Photo: Baumer hhs

The eleven tesla valves are supplied with liquid hot melt via heated hoses by two particularly energy-efficient Xmelt melters from Baumer hhs. This offers the advantage of being able to work with short hoses. The entire adhesive application technology therefore comes from a single source.

Highest precision in adhesive application

The tesla valves apply the hot melt with maximum precision. "That's why our customers can use them in hot melt applications to apply either lines of adhesive or defined rows of adhesive dots. The latter reduce adhesive application by 50 per cent or more. And they usually even improve the reliability of the bonds - after all, dot gluing ensures ideal heat distribution in the adhesive seams, which prevents cohesive fractures and increases the quality of the packaging bonds," says Martin Kotecki, Business Development Manager End of Line Packaging at Baumer hhs, emphasising the flexibility that high-precision adhesive application offers customers.

Also in PackOnTime 2box-system, the tesla valves apply lines of adhesive or defined rows of adhesive dots depending on the box size. "We tend to work with glue dots for small shipping boxes and lines for larger shipping packaging," says Vogel. When the system works with which adhesive application patterns is regulated by the control of the hot melt valves, which in turn is carried out via the system control.

Economic and ecological advantages

Thanks to their electromagnetic drive, tesla hot melt valves are characterised by a particularly long service life. This is because, unlike electropneumatic hot melt valves, they work without dynamic seals, which are generally subject to high wear. Furthermore, tesla valves do not require a compressed air supply. This means that they are considerably more energy-efficient than electropneumatic hot melt valves. And they are practically maintenance-free.

Customised shipping packaging brings considerable advantages to the entire online retail logistics chain. They reduce the space required for storage, sorting, transport and distribution. Filling materials are also no longer required. The volume of waste is drastically reduced. All of this increases profitability and supports the industry's endeavours towards greater sustainability. With their high energy efficiency and the resulting reduction in CO2-emissions and optimised adhesive consumption, the adhesive application systems from Baumer hhs contribute to this.

"In manual packing, online retailers manage to get 80 to 100 parcels ready for dispatch per employee per hour. Our multi-format packaging system easily achieves a multiple of this output," says Vogel, emphasising the short ROI of his company's system. "Working with the Kern project team was fascinating for us, from the first adhesive test to the finished machine. Today we can watch a remarkable machine at work with our first customers," says a delighted Martin Kotecki.

Flexible for individual requirements

PackOnTime 2box has a modular design and can therefore be configured flexibly. The system can be equipped with several loading stations for the products to be packaged. The same applies to the sheet feeders for different corrugated board formats.

The system was developed for the production of customised shipping packaging from corrugated cardboard sheets with a thickness of three millimetres. "It now effortlessly processes corrugated cardboard sheets with a thickness of 2.3 millimetres. This is in line with the trend towards packaging made from thinner corrugated cardboard," concludes Vogel.