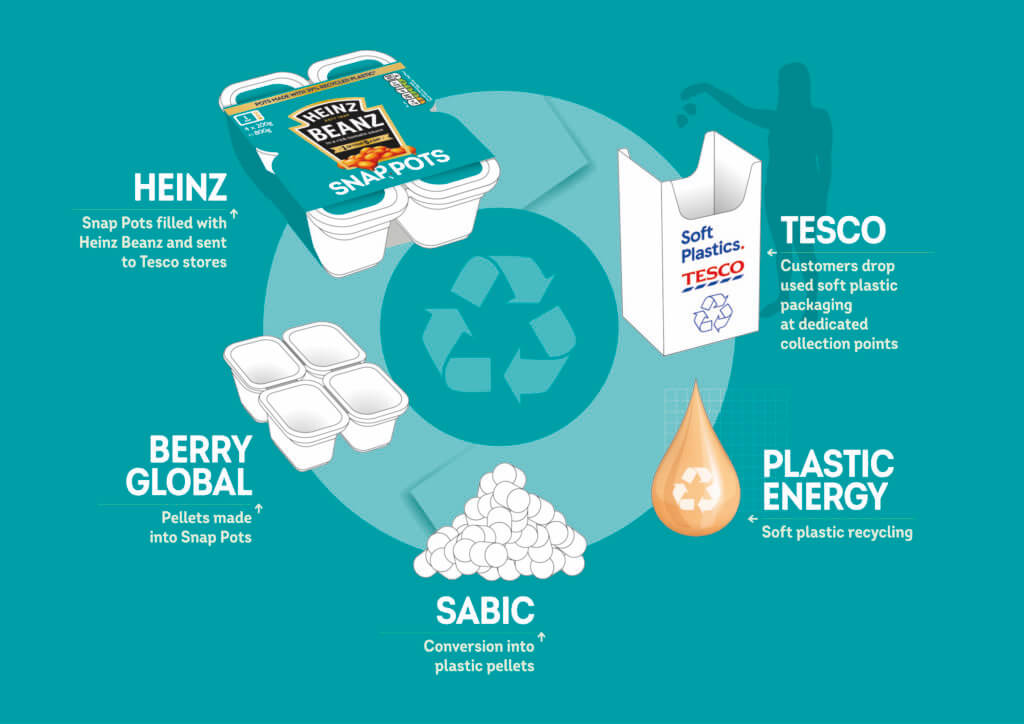

Together with Heinz, Tesco and Berry, Sabic is taking part in a recycling trial in the UK to close the loop for food packaging made from soft plastics.

Chemicals group Sabic has joined forces with Heinz, Tesco and Berry Global in a joint recycling project. Used soft plastic packaging from collection points in Tesco stores is utilised to make Certified circular polypropylene (PP) for the Trucircle portfolio from Sabic and use it to produce microwaveable Heinz Beanz Snap Pots. The new Snap Pots are made from 39 per cent recycled soft plastic.

Consumers are called upon to bring used soft plastic packaging to collection points that Tesco has set up in its supermarkets. Some of the plastic packaging collected there is used in an anaerobic thermal recycling process to produce so-called Tacoil oils. Sabic then uses this to produce a certified recycled polypropylene in granulate form with the same quality as fossil-based virgin material.

Packaging manufacturer Berry Global finally uses this granulate to for the production of new Snap Pots and delivers them to Heinz for filling with Beanz and despatch to Tesco. Empty pots and the sleeves can later be disposed of at collection points close to consumers.

The cooperation fits in with the Trucircle programme and is intended to Transforming the plastics packaging industry into a circular economy to push ahead.

"In addition to our material expertise, we were able to bring together value creation partners and provide significant support, such as in the area of certification or calculating life cycle parameters, in order to help prevent valuable plastic from being lost to landfill or incineration."

Lada KurelecGeneral Manager PP, PET, PS, PVC, PU & Elastomers Businesses at SABIC Petrochemicals

The Snap Pots recycling trial is part of the global promise of Heinzto make all of its packaging recyclable, reusable or compostable by 2025.

"We hope this will sharpen the industry-wide focus on how to address the lack of recycling solutions for soft plastics in the UK. When it comes to developing better packaging that works for consumers and the planet, we can do it together."

Jojo de NoronhaPresident of Heinz Northern Europe.

Jean-Marc Galvez, President of Berry Global's Consumer Packaging International Division, explains: "Such circular solutions help to recover and reuse all those plastics that are not yet recycled today to keep them in circulation and out of our oceans and landfills."

Drop-in alternative to PP virgin material

Flexible packaging is still difficult to recycle, and by 2020, according to Wrap only six per cent of all soft plastic packaging is recycled. Tesco has now started to do so, set up collection points for soft plastics in all of its wholesale stores in the countryto close this gap.

"This innovative collaboration is just one of the ways in which we are recycling the soft plastic returned by our customers into new food packaging. In addition to our endeavours to reduce plastic consumption, we are determined to develop further circular packaging solutions."

James Bullpackaging manager at Tesco

The new microwaveable Heinz Beanz Snap Pots are made of 39 per cent from a certified circular Sabic PP homopolymer for the injection moulding or thermoforming of food packaging. The material fulfils the requirements of safety regulations for food contact and is suitable for this thin-walled application. an ideal drop-in alternative to PP virgin materialwithout restrictions in terms of processability or mechanical performance. The proportion of recycled material in the snap pots is validated by means of mass balancing in accordance with the requirements of the International Sustainability & Carbon Certification (ISCC) PLUS programme.

SourceSabic

Sabic - More news

Packaging made from cooking oil

Bread packaging made from post-consumer recyclate

Packaging with renewable content for rice

In-mould labelling solution with renewable polymers