Dematic automates the new warehouse of Vöslauer Mineralwasser GmbH. As part of the expansion and modernisation of the logistics centre at the company's headquarters in Bad Vöslau, the intralogistics specialist is building a five-aisle automated high-bay warehouse for the Austrian mineral water bottler.

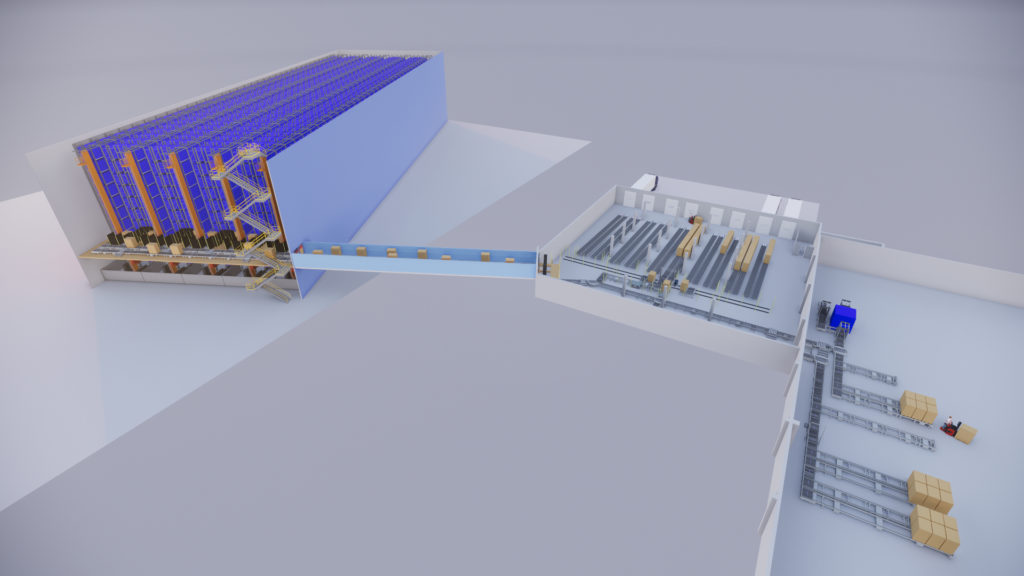

The new silo-style warehouse will have 20,000 storage locations and a pallet conveyor system with automatic precision measurement and control. The customised solution is connected to the existing dispatch building via a conveyor bridge and two pallet lifters. In the high-bay warehouse, Dematic storage and retrieval machines with telescopic forks ensure the automatic and double-deep storage and retrieval of pallets.

Through The beverage company is not only increasing its capacities with the new plant, but also raising the level of automation at the site. Completion and commissioning of the plant are planned for the first quarter of 2022.

The order comprises the complete intralogistics automation including software solution for the new high-bay warehouse as well as the connection to the dispatch area, which is centrally located between the new building and the existing block storage halls. The new concept for the central warehouse in Bad Vöslau was developed by the technical consulting and planning company Xvise innovative logistics GmbH.

Ten storage levels and five aisles

The Dematic solution has a high-bay pallet warehouse with ten storage levels and five aisles, each of which is supplied by storage and retrieval machines. With the help of telescopic forks the pallets are automatically stored or retrieved double-deep. Two pallet lifters then transport them onto a conveyor bridge that runs over a public road and connects the warehouse with the dispatch building. There, the pallets are distributed on inclined roller conveyors and automatically staged at the loading gates.

„The solution enables us to achieve a fully automated and smooth material flow between the new high-bay warehouse and dispatch.“ Reinhard Deimel, Supply Chain Manager at Vöslauer Mineralwasser GmbH

The intralogistics specialist has integrated the software for the high-bay warehouse directly into the existing SAP WMS using the Dematic SubSuite extension. The one hundred per cent SAP solution does not require external software. The mineral water company expects to be able to process up to 250 pallets per hour with the system.

The conveyor technology supplied by Dematic also includes BK25 heavy-duty unit load conveyors, roller and carrier chain conveyors as well as roller lifting and turntables. Dematic has also installed fire protection doors at the conveyor system passages. The logistics system is controlled using programmable Siemens S7 controllers. Dematic has also integrated the WinCC process visualisation system developed by Siemens into the solution to monitor the technical processes. It enables a simple and clear flow of information for all data and at the same time acts as an interface between the system and the operator. „In this way, we are informed about the current status of the system at all times. We can also visualise and derive potential for optimisation,“ says Reinhard Deimel.

[infotext icon]Dematic is an intralogistics innovator that develops, builds and supports intelligent, automated solutions for manufacturing, warehousing and distribution environments. The company employs around 10,000 people in more than 25 countries and has realised more than 6,000 customer installations. Dematic, headquartered in Atlanta, Georgia, USA, is a KION Group company[/infotext].Source: Dematic