Taking responsibility: Werner & Mertz, the Mainz-based manufacturer of cleaning products, has consistently pursued the „Design for Recycling“ approach for years. Not only since the launch of the Recyclate Initiative in 2012 has the company been a pioneer when it comes to not only developing sustainable products and producing them accordingly, but also promoting the reuse of raw materials from packaging.

„A Credible eco-product can only come from a company that consistently implements sustainability in its own actions - a company that lives ecological awareness, economic foresight and social responsibility every day. Sustainability in all business decisions creates trust. We are convinced that more and more consumers want to know the economic, social and ecological conditions under which their products are manufactured,“ explains the Managing Partner Reinhard Schneider the position of the family business Werner & Mertz to the point. This includes designing plastic packaging in such a way that it can be reused to a high standard.

Innovative idea, strong cooperation

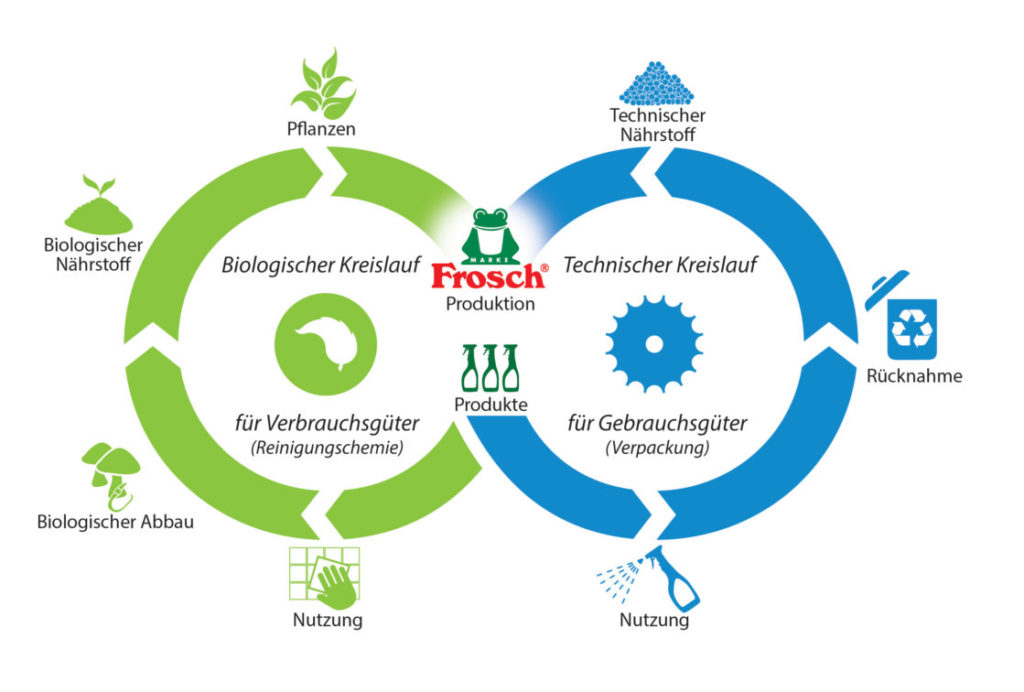

The Recyclate initiative was founded in 2012 by Reinhard Schneider. It pools its expertise in order to effectively recycle PET, PE and PP waste from the Yellow Bag and thus turn it into an environmentally friendly product. closed material and production cycle to lead. The concept is based on high-tech developments and has been designed from the outset as a „Open Innovation“ to successfully promote this sensible investment in the future beyond its own industry boundaries. In addition to Werner & Mertz GmbH, the members are Der Grüne Punkt - Duales System Deutschland (DSD), ALPLA Werke Alwin Lehner GmbH & Co. KG and NABU - Nature and Biodiversity Conservation Union Germany.

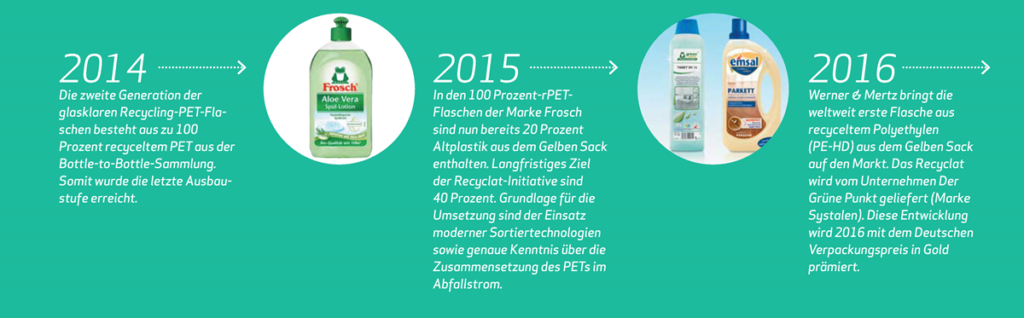

The company has consistently pursued the principle of using recyclates. Thanks to its diverse activities and projects, the Mainz-based company is several development steps ahead of the market. The focus is in line with the new packaging law, which will come into force in Germany on 1 January 2019. All endeavours are also in line with the European Commission's plans for the plastics strategy by 2030.

We have Property Sander, who has been responsible for the development of the company's sustainable packaging for seven years and has played a key role in shaping it, was asked about motivation, trends and other packaging-related goals.

pj: Mr Sander, how important do you think packaging development is in the context of the (Frosch) Recyclate Initiative?

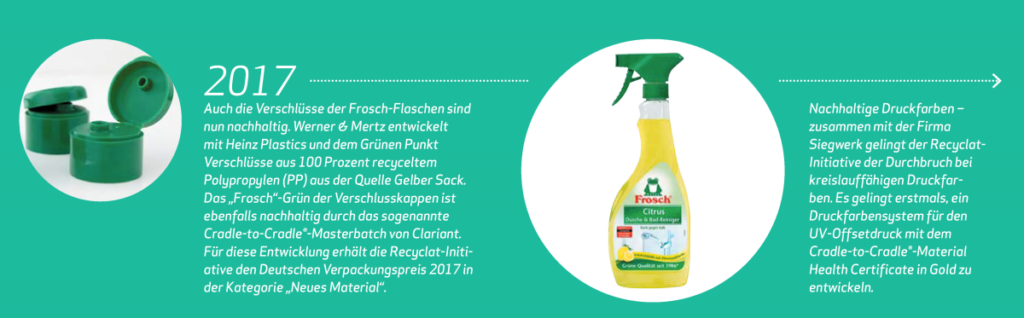

Immo Sander: The recyclate initiative as part of the Frog initiative Werner & Mertz is consistently dedicated to the development and production of recyclable packaging in accordance with the Cradle-to-cradle principle. The use of state-of-the-art recycling technology, knowledge sharing, technology transfer and high-quality recycled materials are the key to success in packaging development. By working with our partners to master the unknown challenges of using ever higher proportions of recyclate in our packaging and also making packaging fit for the circular economy, we are proving that high-quality recycled packaging is not only realisable, but its production can also be economical.

pj: What prompted the company to take on this particular challenge so consistently?

Immo Sander: Consistently sustainable action is firmly anchored in the Company philosophy. A sustainable cleaning product also needs sustainable packaging - this is the basic idea behind the Recyclate Initiative. Just like our cleaning products, the packaging should not harm the environment and should be integrated into cycles. We want to fulfil this goal, also because consumers trust in our consistent actions.

pj: As a trendsetter, Werner & Mertz is ahead of developments in many areas. To what extent do the demands of the market/consumers flow into the decisions? In other words, can the effect of new packaging variants on consumer behaviour be measured?

Immo Sander: You have recognised correctly: With our developments we want to „Benchmark“ and always be one step ahead. We have already achieved this with numerous pioneering achievements. When developing packaging, it was important to keep the consumer in mind. The plastic bottles made from recycled material are therefore characterised by their appearance and properties. similar to bottles made from virgin material. However, the consumer can recognise differences on closer inspection. Additional information on stickers and on the Internet provides interested consumers with clear and sufficient information. In addition, we do not pass on the higher raw material and manufacturing costs to the consumer.

The awards that Werner & Mertz and the Frosch brand in particular have received in various consumer polls prove that consumers honour the consistent continuation of the environmental concept.

pj: As we all know, the difficulties are in the details: What were or are the particular challenges in the developments on the front line?

Immo Sander: Working on the „front line“ is a challenge in itself. There was hardly any experience from others that we could use as a guide. We therefore had to gradually work our way up until we achieved the desired result. For example, no-one before us had ever tried to fill bottles. 100 per cent recycled, translucent HDPE to produce. Developments like these require motivation from everyone involved to pursue an ambitious goal, as well as the courage to invest the time and resources involved and accept setbacks.

But the good thing is that we are not alone in the recyclate initiative, we can pool our expertise perfectly. And the technology is also evolving. Developments that were unthinkable a few years ago can now be realised.

In the meantime, we can Modern sorting technologies with PET, HDPE and PP We already process three different plastics from the Yellow Bag household collection into high-quality recycled packaging and closures. We are also focussing on the other components of our packaging: With sustainable printing inks we achieved a breakthrough in 2017 by developing the first UV offset printing ink system with the cradle-to-cradle®-Material Health Certification.

pj: Mr Sander, finally, we would like to take a look into the future: what steps are planned for the coming years?

Immo Sander: I still have a while to go before I retire, and until then I would like to realise many of the ideas that were born as part of the Recyclate Initiative. We are currently working with the Mondi Consumer Packaging GmbH a Fully recyclable bags made from polyethylene material and thus realised a goal we have been pursuing for years. This will be used in our Frosch packaging from next year. We are also continuing to work on innovative developments for labels in order to find effective solutions for recyclable and removable adhesives.