Complexity and volatility are constantly increasing in the pharmaceutical and healthcare industry - this is also noticeable in the procurement of packaging. The digitalisation of the supply chain offers the right answers to this challenge: modern methods can make procurement processes significantly faster, more cost-effective, more reliable and more efficient. more sustainable.

The pharmaceutical and healthcare industry has developed into one of the most important global growth markets in recent decades. A rapidly growing world population and the demographic shift towards ever older societies ensure that the demand for medicines and other pharmaceutical products is constantly increasing. For most manufacturers, however, the market environment has also become much more dynamic and volatile. The reasons for this are complex and range from international competition and new forms of therapy and administration to increasing individualisation. In addition, more and more products are coming onto the market in an ever shorter time.

All of this is leading to a lasting change in production behaviour in the pharmaceutical and healthcare industry. The Batch sizes of individual orders decrease significantly, while conversely the order quantity increases. This results in more frequent changes and changing requirements in the production process. In addition, shorter lead times and high cost efficiency along the entire supply chain are essential in order to successfully meet the challenges of the market and competition. This has an impact on the manufacture of the pharmaceutical products themselves - and even more so on the procurement and production of the associated packaging.

Volatility causes unnecessary costs

The individualisation of pharmaceutical and healthcare products is leading to a increasing variety of articles, The secondary packaging, which is often designed differently depending on the customer or country, is particularly affected by this. Added to this is high time and cost pressure. This makes it increasingly difficult for packaging manufacturers to plan their production in advance and to utilise capacities evenly and efficiently. Pharmaceutical companies, meanwhile, are finding it difficult to Correctly estimate packaging requirements in advance and times as well as production and logistics processes accordingly. The result is unnecessary and avoidable costs, such as storage space, transport, machine downtime or the destruction of superfluous materials.

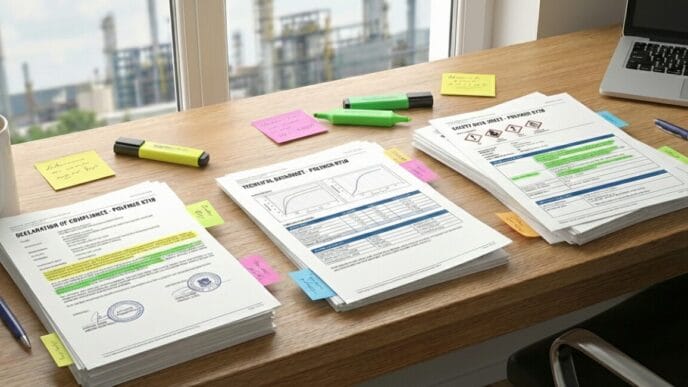

To counteract this, it is necessary to precisely analyse the entire supply chain for the procurement of pharmaceutical and healthcare packaging and to optimise it across all processes. In many cases, there is even talk of a transformation towards a „Digital Supply Chain“, in which all material, product, people and information flows are integrated across various logistics channels, from the raw material to the end customer. The potential benefits are immense: the forward-looking analysis of internal and external data makes it possible to better predict future requirements and fulfil them more quickly. Detailed information, for example about customers, opens up new opportunities for Customised products. The transparent exchange between companies, suppliers and customers makes the entire value creation process more accurate and reliable. The result is considerable cost savings in almost all processes involved in value creation.

Comprehensive data exchange as a basis

The manufacture of pharmaceutical products and the procurement of the packaging required for this creates a Variety of relevant data along the process chain. There is huge potential in storing and analysing this data and sharing it with other partners involved in the supply chain. Manufacturers of secondary packaging, for example, can use forecasts and historical order data from pharmaceutical companies to optimise their own processes from the outset, purchase materials at an early stage, prepare tools and plan production capacities.

Conversely, pharmaceutical manufacturers can, for example, analyse their suppliers' batch protocols and improve their overall plant efficiency with information on material properties. After all, properties such as the thickness of a folding carton have a direct influence on the packaging behaviour. Information from the packaging line in turn provides valuable insights for future orders - for example, which material combinations work well on a particular machine and which do not. The result is significant improvements along the entire process chain, enabling pharmaceutical companies to save both time and money.

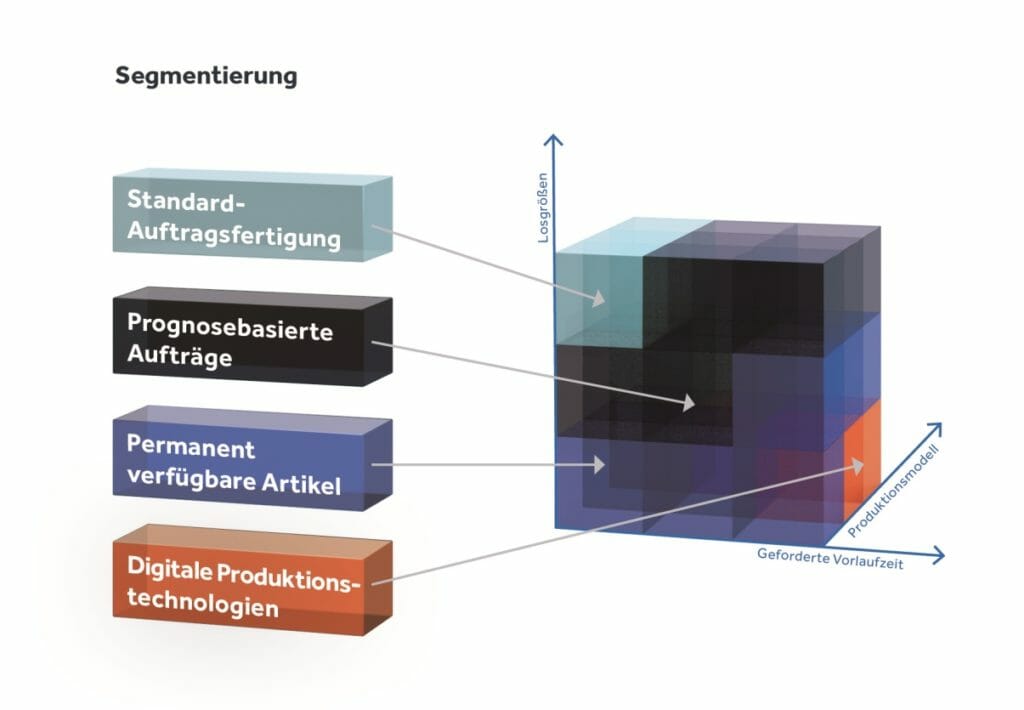

In order to utilise the data obtained profitably, a In-depth analysis required. Secondary packaging for the pharmaceutical and healthcare industry differs in a variety of parameters, including batch size, lead time and order cycle. The historical and forecast data that the packaging manufacturers receive from the pharmaceutical companies makes this possible, Organise orders into several clusters and differently within production.

Consistent orders in large quantities with long lead times, for example, can be produced and delivered as usual on an order-related basis. For items with more chaotic order patterns and fluctuating quantities, on the other hand, it can be worthwhile planning them for production in advance if the forecast data indicates a corresponding demand. Products that are usually only ordered in small quantities but need to be available quickly can even be produced for stock and stored until the corresponding customer order is received. Digital production technologies are also ideal for particularly customised orders in small batch sizes with extremely short lead times, as they are significantly faster and more flexible in such cases compared to the traditional manufacturing process.

Steps towards a more efficient supply chain

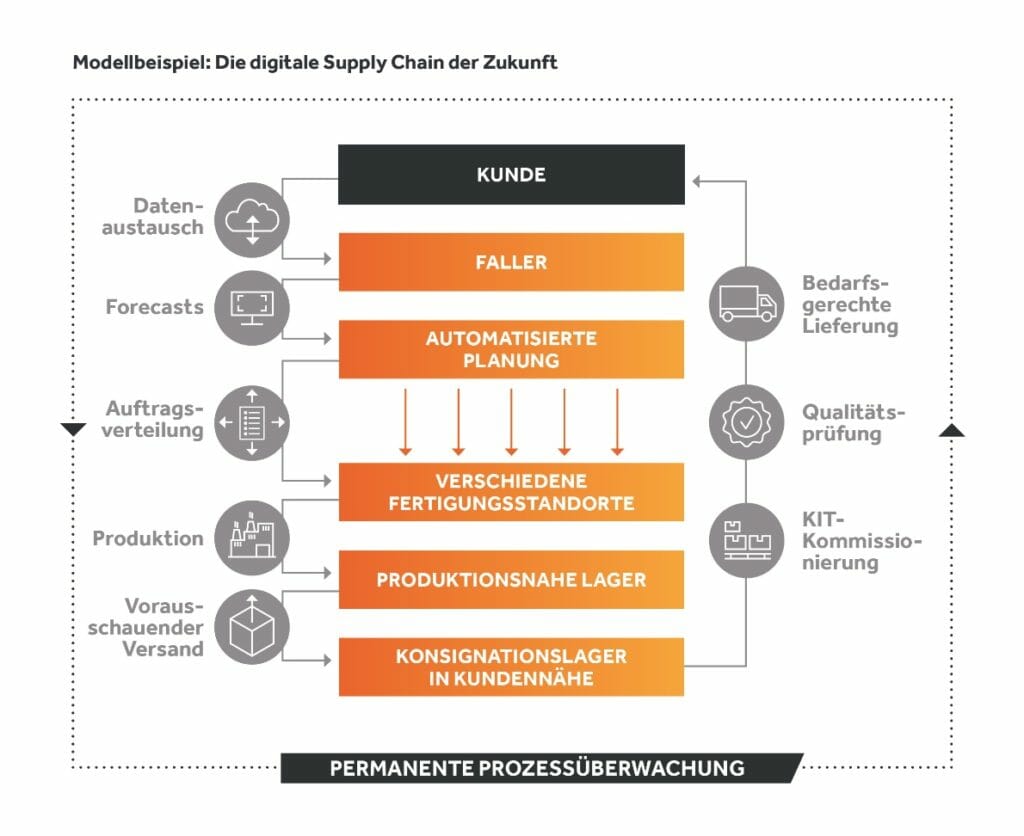

The results of the data analysis and segmentation also lead to specific recommendations for action. There are a variety of approaches and methods along the entire supply chain: for example, the packaging manufacturer can assume complete responsibility for inventory management for its customers, distribute orders to various production sites via a central platform and then consolidate them again, or take responsibility for the quality inspection of the delivered goods as a so-called certified supplier. By implementing the individually suitable steps and integrating them into a Overall system controlled across processes integrated, procurement can be organised in a more time- and cost-efficient, reliable and sustainable manner.

In order to drive forward the digitalisation of the supply chain for pharmaceutical packaging, it is important to have the right partner at your side - like Faller PackagingHeadquartered in Waldkirch, Baden-Württemberg, the company has specialised in customised solutions for pharmaceutical secondary packaging for more than 30 years. As a full-range supplier, Faller Packaging develops and produces folding cartons, leaflets, labels and combination products from a single source - and all from a single source. both standard packaging and customised packaging according to customer requirements. In addition, the manufacturer also has a high level of expertise in the implementation of digital supply chain solutions and supports its customers in sustainably optimising their procurement processes.

Modular consulting with specific recommendations for action

The process is usually as follows: Faller Packaging first determines the complexity of the supply chain between itself and the customer by simply analysing the available order data - free of charge and without obligation. This is supplemented by experience-based estimates of potential cost savings. The result is a Immediate indication, how much savings potential is available and at which points in the supply chain it can be found.

In addition, Faller Packaging offers modular supply chain consulting with various service modules: Data analyses and recommendations for action help customers to independently optimise their processes and generate savings. Training courses raise awareness of the behaviour that can be used to manage the increasing complexity of the supply chain. And during an on-site process and data analysis, companies receive a detailed action plan and specific savings calculations.

The result is a collaborative partnership that makes the procurement process significantly more efficient, dynamic, faster and more cost-effective thanks to a high level of transparency. Faller Packaging supplies the suitable complete packaging solutions from a single source - and, as a competent consultant, also ensures smooth logistics. This pays off: With its digital supply chain solutions, Faller Packaging enables its customers to achieve savings in total operating costs of around 20 per cent.

[infotext icon]Faller Packaging has specialised in customised complete solutions for pharmaceutical secondary packaging for more than 30 years. Digitalised and optimally coordinated processes ensure maximum efficiency, sustainable production and reliably fast delivery times. Faller also offers customised logistics services and supply chain concepts[/infotext].The article "How the digital supply chain is making packaging procurement more efficient“ is the cover story of the packaging journal June issue 2021.