Packaging machine manufacturer Schubert is countering the increasingly complex market requirements with greater product diversity and smaller batch sizes with flexibility. The modular TLM machine concept, additive manufacturing and the new co-operative robots offer opportunities here.

Faster, more flexible, more sustainable - the packaging industry is currently faces some challenges. In order to realise these requirements economically and ecologically as a manufacturer in the packaging process Highly flexible machines and consistently efficient processes necessary. Schubert offers the modular system of its TLM systems This is already an advantage that the Group is continuously driving forward by developing new robots and digital solutions.

In order to capitalise on trends such as Demand for alternative packaging materials the manufacturer is focussing on flexible application options and the ability to adapt to new requirements when developing new systems. tests new materials for quality and process suitability, even with its own machines. Schubert meets the industry's need to launch new formats onto the market at ever shorter intervals with machines that enable fast format changes through the use of state-of-the-art technologies and immediately deliver error-free production results without a start-up curve.

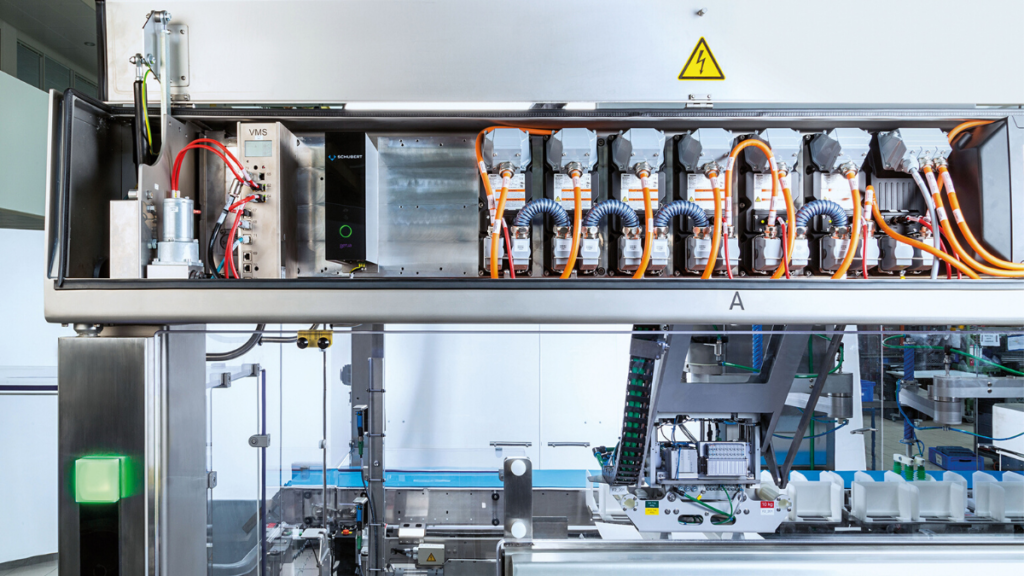

Pick-and-place robots for higher power density

Who above all A lot of power in a small space must accommodate or More manoeuvrability for product handling now gets the specialised T4 and T5 robots the right solution. The design of the new Pick-and-place robots is based on the well-known Delta robot type. Their limited rectangular working area predestines them for a High performance in the smallest of spaces: In a up to six of the new four-axis T4 robots can work simultaneously on a single TLM frame. work. Another new option for automated processes is offered by the Variant T5. It has a fifth axis, with which products can be swivelled and tilted.

Virtual parts warehouse with 3D printing on demand

The 3D printing revolutionises not only the machines, but also warehousing. Because Electronic design data can be generated „on demand“ in a matter of seconds.“ all over the world. Schubert is now making this access to verified and certified print data possible - with the new Part streaming platform of the subsidiary Schubert Additive Solutions GmbH. The virtual warehouses is fast, reliable and economical and represents a major step towards safe, flexible production. The digitally stored parts are Available everywhere, eliminating long waiting and delivery times.

In addition to simple Spare and wear parts can be used to 3D format parts for robot tools print via the part streaming platform. Permanently used equipment and devices also offer many possibilities. One of the most secure data connections between the customer's own printer and the new platform, the Industrial Gateway GS.Gate from Schubert. The digital gateway also opens up new options for even more fail-safe and economical production thanks to the targeted collection of machine data.

Industrial Gateway GS.Gate now standard in every new TLM system

Big data is the new currency - also in the packaging industry. But storing machine data alone is not enough. If you really want to benefit, you need a Sensible analysis of the important key figures and a One hundred per cent protection against attacks from the Internet. Schubert now makes both possible in series production: a GS.Gate is integrated into every new TLM system as a Industrial Gateway integrated. This can be used to Detailed analyses of system productivity can be called up. The results are available either on the Customer platform GRIPS.world or on the machine's operating terminal. This analysis can then be used to derive potentials and possibilities for improving the OEE (Overall Equipment Effectiveness) of the system and thus the added value.

Cobots - the next level of automation

With the co-operative robots, that operate without a safety cage can be Automate packaging processes for small batch sizes and optimise it significantly. For its new Cobot construction kit Schubert is developing a complete system. The new co-operative robots from Schubert will be presented at the interpack 2021 from 25 February to 3 March 2021 in Düsseldorf.

Source: Schubert