Corrugated board printing with minimum set-up time and low waste while significantly improving overall system productivity: With this in mind, a new digital inkjet printing solution has been developed to help printers meet the increased challenges they face on a daily basis. We talk about this with Matt Condon, Manager at Domino.

Today, corrugated board converters are confronted with market conditions that were commonplace for label printers ten years ago: increased demands from brand owners for shorter print runs, shorter lead times and more variants. The question is how they can meet these market conditions cost-effectively.

Added to this are the challenges regarding the personalisation of packaging, shelf-ready packaging and the impact of COVID-19. The pandemic has temporarily accelerated the already predicted market growth in the e-commerce sector because safety and hygiene are becoming increasingly important. All of these factors are contributing significantly to the trend towards digitally printed corrugated board.

Following the company's entry into the label printing sector in 2012 Domino quickly with digital printing machines in the inkjet technology sector. The company now wants to repeat this success in the corrugated board printing market.

A conversation about corrugated board printing of the future

Mr Condon, with this new development, the company aims to offer its customers a more comprehensive range of services to support them and help them realise profitable market opportunities for small and medium print runs. In your opinion, what are the main reasons for this decision?

Matt Condon: Domino sees the corrugated converting market as the next segment that will be directly impacted by how brands focus on targeted marketing campaigns such as personalisation and seasonal promotions that incorporate the changing market conditions mentioned earlier. We believe that we are well positioned to meet the new marketing requirements as we have successfully adapted to these changes in other market segments such as the label converting market.

What can the highly automated, digital Domino X630i single-pass inkjet press do? Or, to put it another way, what makes it so special?

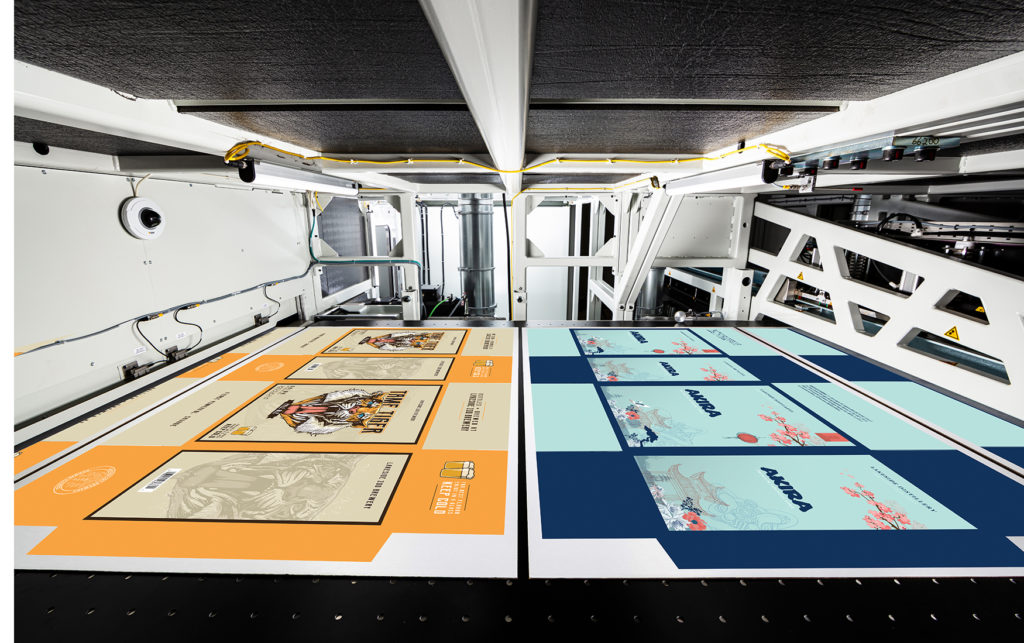

Matt Condon: The Domino X630i offers corrugated converters several unique features: Firstly, the company has one of the most compact machine configurations currently available on the market. The length of the inkjet printing machine itself is just under twelve metres. It also has an air-conditioned enclosure. These features give corrugated board processors maximum flexibility when choosing the installation location within a corrugated board production environment.

Domino has implemented Generation 6 inkjet technology with the unique Domino i-Tech features CleanCap, ActiFlow and StitchLink. It has proven itself in the market with almost 1,000 installations worldwide (Domino N-Series & K-Series). The individual i-Tech functions provide additional automation to avoid manual intervention by the operator on the inkjet printer. This automation offers corrugated converters maximum production efficiency and uptime. The system used in the X630i Generation 6 inkjet system is supported locally by the Domino service teams, as the existing structures can be utilised directly.

Finally, we offer a servo-driven sheet feeding system developed by Sun Automation with the advantage of continuous feed. Sun Automation is one of the leading companies developing robust and state-of-the-art corrugated handling systems. This reliability gives corrugated converters an added advantage in terms of line efficiency.

You call your water-based CMYK ink set Domino AQ95 an innovation. What options/possibilities does this open up for printers, their customers and, last but not least, for recycling?

Matt Condon: Domino AQ95 ink is a pigmented, polymer-based water ink that utilises Domino's unique i-Tech PolyM technology. This ink enables the Domino X630i inkjet printing unit to print on coated and uncoated corrugated materials without a separate primer, so that the corrugated board can be recycled as usual.

In addition, the ink set is also suitable for many non-direct food packaging applications that fulfil the Swiss regulation and are Nestlé and EuPIA compliant.

Domino Digital Printing Solutions had already prepared the market launch of the somewhat different printing press for drupa 2020. What has happened since then?

Matt Condon: Due to COVID-19, DRUPA could not take place this year. Domino was undeterred by this and stuck to the date for the launch of the X630i was finalised in June 2020. The development was presented to the interested public at virtual events for the British, European and North American markets.

In the meantime, the X630i is being used under production conditions at HSG in Bradford, UK.

Are there other users? What are the experiences in practice?

Matt Condon: Domino was able to install the X630i at Kentucky-based company Independent II in September 2020. COVID-19 delayed this installation, which was originally scheduled for March 2020. The system is now fully operational and the customer has produced its first jobs on the press very successfully in recent weeks.

[infotext icon] The i-Tech CleanCap-function is an automated cleaning and sealing solution for the inkjet print heads and ensures reduced maintenance. i-Tech ActiFlow offers continuous ink circulation for uniform printing results and i-Tech StitchLink enables precise alignment of the print heads to produce print results of the highest quality. Digital Printing Solutions is a division of Domino Printing Sciences. Founded in 1978, the company specialises in the development and manufacture of inkjet digital printing systems as well as its globally available aftermarket products and customer services. Domino is an independent division within Brother Industries. [/infotext]