How can you make good things even better? Swiss company Delica AG posed this question to packaging machine expert Schubert. A successor solution for the existing picker line is now being used in the packaging process, which achieves even more efficient product handling on the same footprint using the double-pick method.

Whether for an afternoon snack or as a tasty snack between meals, Delica's biscuit specialities, which have been produced since 1928, are a piece of Swiss confectionery tradition. Over the years, the „Guezli“, available in different varieties with and without a chocolate coating, have gained a large fan base far beyond their country of origin. Delica employs a total of around 2,200 people under the umbrella of Migros Industrie. The production site in Meilen in the canton of Zurich also employs Schubert-machines have long been an integral part of production. In August 2023, Delica turned to Schubert to Replacement for a picker line which was used in the biscuit packaging process.

Flowpacker to increase efficiency

While a one-to-one exchange was originally planned, it became clear during the course of the consultation that the possibilities of today's technology would allow a one-to-one exchange. more efficient solution for handling a total of ten packaging formats could be realised. A key challenge was to find a solution for this product range that was able to process both flowpack and tray products and enable format changeovers without major time and labour costs. To achieve this, it seemed advisable to fundamentally scrutinise the efficiency of certain process sequences.

In this context, the post-process for flow-wrapping without trays, which was previously carried out manually by four workers and required further transport to another floor, promised great potential for optimisation. As Delica also favoured smooth running, quick and easy cleaning and high Flexibility in format changeover were at the top of the wish list, it quickly became clear that the Schubert Flowpacker would be the ideal solution.

More throughput, less effort for cleaning and maintenance

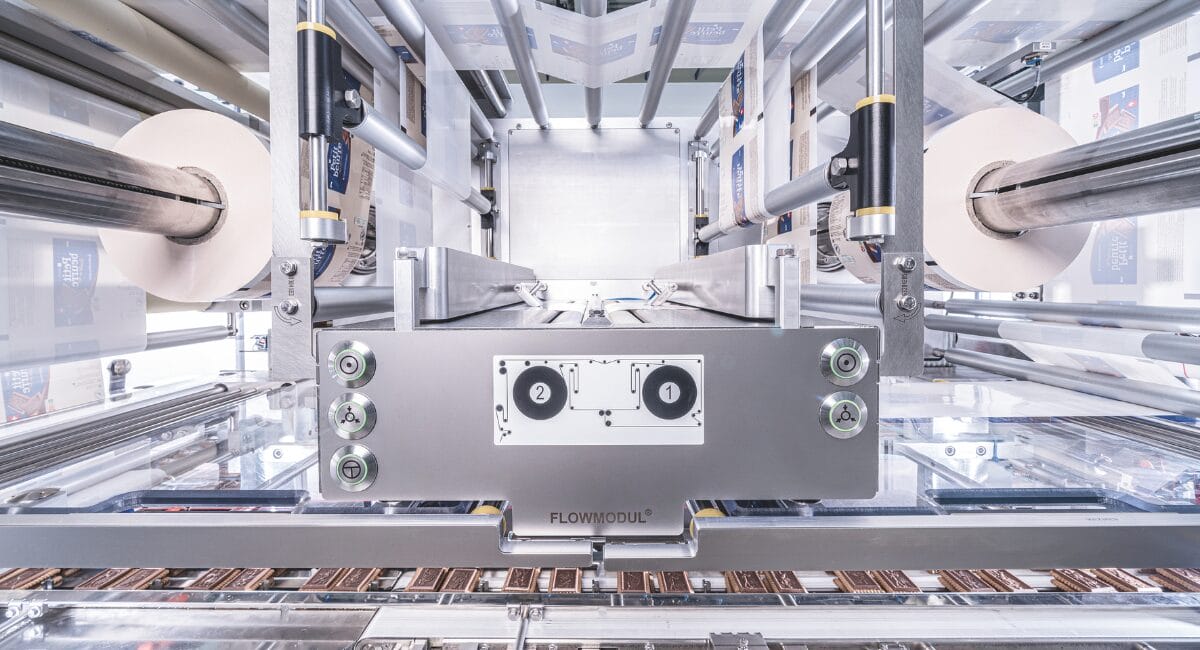

With its space-saving machine layout, the new Flowpacker blends seamlessly into its installation site and offers significantly more space. Functionality and performance. Instead of the previous ten, eight F4 arms in the double-pick process now enable a throughput of up to 728 products per minute, without compromising the smooth running of the machine at this cycle rate. Schubert's advanced image processing system ensures that the products are not only deposited quickly, but also always in perfect condition from the centrally positioned product belt onto the chain with the tray formats or optionally onto the belt for the flowpack format.

Especially when handling the partially or fully chocolate-coated biscuits, the Integrated film dispenser with short chain makes the most of its advantages. Since the pre-grouping takes place on a belt, cleaning is easier. Due to the shorter chain length, fewer carriers need to be replaced when changing formats. Only one operator is required for the process, and as no carrier cassette is needed for this, costs can be saved.

From tray to flowpack with one click

As the magazine plate is the same for all formats due to identical tray dimensions, the changeover can be carried out by a single person. If, as in the case of Choc Petit Beurre, there is both a flowpack and a tray format, a single click on the operating terminal is all that is needed for the changeover. If the products are to be packed directly into flowpacks, the tray denester is simply removed from the packaging process without any further conversion work. In the flow module, the proven Combination of longitudinal sealing using ultrasonic technology and subsequent transverse sealing with heat sealing for a gentle and secure seal. The flying cross-sealing unit also ensures that the sealing time and temperature remain constant in the event of an uneven flow.

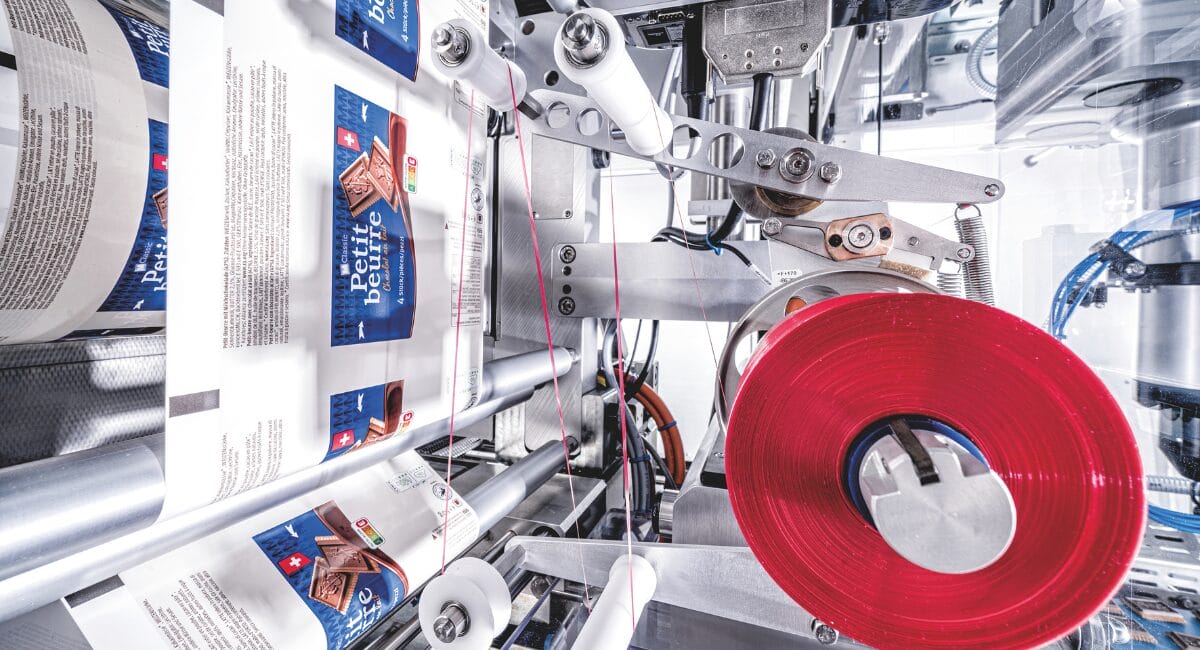

As the packs produced in this way are very narrow, two different forming shoulders are used to cover different formats. A novelty and - for space reasons also a small challenge - was the Integration of a tear strip in the flowpack which was solved by the Schubert engineers. The red plastic thread is unwound parallel to the Flowmodul film, to which it adheres by means of an adhesive layer, and then sealed.

Equipped for the future

Sustainability is playing an increasingly important role in the confectionery industry. At Delica in Meilen, where a new process cooling system that uses water from Lake Zurich was put into operation in 2021, the responsible use of natural resources is also being practised. Therefore, the design should also take into account the possibility of later switch to more environmentally friendly paper trays by integrating a second F2 robot. In the current version, the tray denester has therefore been dimensioned somewhat more generously. And another requirement scenario has also been taken into account: if products are to be placed in the tray not only flat but also along their longitudinal edge in future, this can also be realised using the integrated swivelling chain conveyor. Delica was impressed by these performance features across the board.

„With its ability to process tray and flow-wrapped products, the new Flowpacker basically combines two machines in a single, highly efficient and flexible solution. We can now productively utilise the personnel capacities freed up as a result elsewhere.“

Kaspar Huber, Deputy Technical Manager at Delica's Meilen site