At Anuga FoodTec in Cologne, Nord Drivesystems will be showcasing drive solutions for food and beverage production. The solutions impress with their efficiency and reduced maintenance.

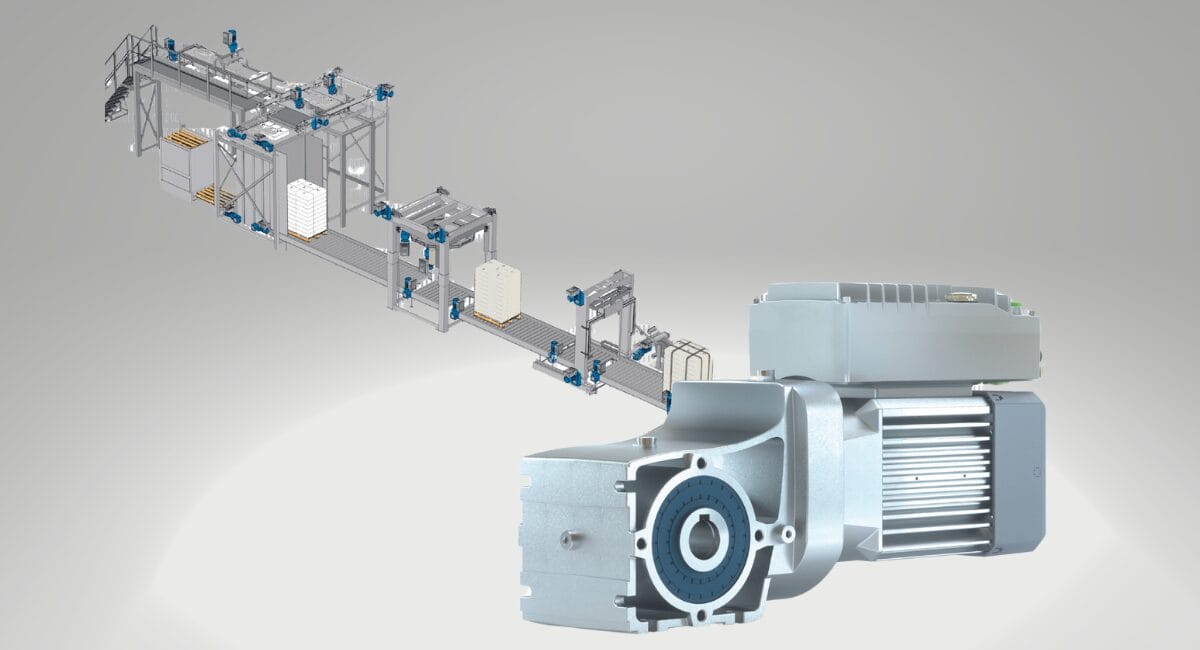

Drive solutions from Nord Drivesystems promise high energy efficiency and low total cost of ownership (TCO). In the packaging of food and beverages, for example, Nord asynchronous motors can be used in end-of-line packaging. Cost benefits of up to 50 per cent realised are used. Centrally controlled servomotors are usually used here. Controlled asynchronous motors from North are an efficient and economical alternative. When used with decentralised frequency inverters such as the Nordac On, components such as control cabinets are also eliminated, and the Reduce cabling and set-up costs clearly.

If a control cabinet inverter is required, we recommend the Nordac Pro SK 500P, which is ideal for the industry with a power range of up to 22 kW. All Nord frequency inverters are equipped with the PROFIsafe module assembly for safety functions. Nord also offers suitable solutions for other food and beverage processing stages. The Nord IE5+ synchronous motor impresses with maximum energy efficiency and exceeds the previously defined efficiency classes. As the permanent magnet synchronous motor realises its constant torque over a wide speed range, it enables Reduction of drive variants in an overall system. This in turn reduces administration costs and therefore also the TCO.

The DuoDrive has been specially optimised for the requirements of the food industry. In this patented geared motor unit, an IE5+ motor is integrated into a spur gearbox. This not only achieves a high level of system efficiency. Fewer wearing parts and reduced maintenance requirements ensure further positive cost effects.

Source: Nord Drivesystems

Nord Drivesystems at Anuga FoodTec: Hall 7.1, Stand A010