Functioning automation technology is essential for food manufacturers and processors: they need intelligent technologies and services to fulfil the high food safety standards as efficiently, compliantly and resource-efficiently as possible.

Consumers not only demand a long shelf life, but also permanent availability of the entire product range. The food should also be of high quality and free from any impurities or foreign bodies. In addition, the demand for food is becoming significantly more differentiated and therefore more fragmented. This not only represents an additional challenge, but also an increased effort for the production process.

Producing the required quantities of food requires an increasingly automated process chain. And not only consumers, but also retailers are placing high demands on food manufacturers and processors. In addition to complying with legal regulations, they are increasingly demanding additional certifications from their suppliers. Issues such as transparent product traceability and fast response times in the event of product recalls play an important role. There are also increased requirements for logistics systems and supply chains.

Picture: Sesotec

The customer is king

Sesotec, a leading manufacturer of product inspection and material sorting systems in Schönberg, Bavaria, has set itself the task of helping the food production industry to produce safe food profitably and at the same time waste less of it. To this end, the company offers suitable application solutions for all process stages, products and conveyor types, as well as for all critical control points in the production process.

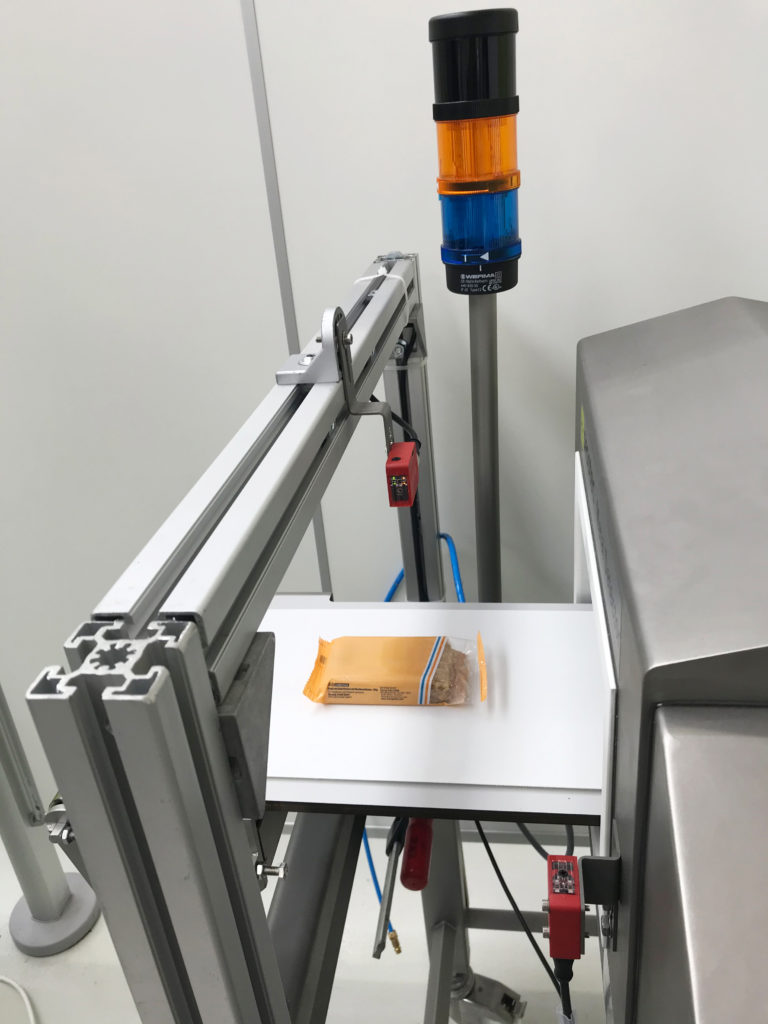

In the area of conveyor technology at the Foreign object detection systems use various sensors from the Leuze electronic GmbH in use, that have proven themselves over the years. The DRT 25C from Leuze is being tested in the Sesotec technical centre especially for complex, customer-specific applications that cannot be solved with standard detection. Its completely new functional principle is based on Contrast Adaptive Technology (CAT).

Precise technologies for efficient processes

The food industry has become a complex, globally intertwined system with many stakeholders. „Manufacturers need precise technologies to comply with legal food safety standards,“ explains Hermann Sammer, Head of R&D at Sesotec. However, an increasing degree of automation means fewer staff and less control by employees in the production chain. This also increases the risk that any foreign bodies in food are not recognised.

Metal detectors, such as those manufactured by the company, are suitable for detecting metallic contaminants such as wires or chips. X-ray systems are available for detecting contaminants from non-metallic materials such as glass or plastics. Sammer has been working with Leuze for many years. Always with the aim of finding even better and more efficient solutions for its customers' demanding applications. Optical technologies from Leuze are used for reliable detection and correct labelling and assignment. They ensure that the packaging contains what is labelled on it.

Picture: Leuze

Minimising waste together

Sesotec is very satisfied with the Leuze sensors that have been installed as standard in the machines and systems for years. Nevertheless, the company is always open to new ideas and technologies, which is how the test operation came about of the completely new Leuze sensor DRT 25C

"Our corporate philosophy is very much in line with that of Leuze. We also do not see ourselves as a standard supplier of individual metal detectors. Rather, our aim is to offer our customers specific, complete solutions tailored to their specific application and requirements. And these do not just consist of our own components. They also include the complete sensor technology. This is the only way we can help our customers to increase their profitability despite the additional costs of automated product inspection.“ Hermann Sammer, Head of R&D at Sesotec

Brigitte Rothkopf, Director Corporate Communication at Sesotec, emphasises: „Despite all the economic efficiency, it is just as important to us to make a positive contribution to minimising food waste. For us, this is not only an ethical problem, but also an economic one.“

New at the start: The DRT 25 C

The new DRT 25C switching Leuze sensor promises to reliably detect any type of object and product packaging, such as those inspected by metal detectors and tested for contamination in the food industry. Regardless of their colour, shape and surface texture. Whether flat, shiny, perforated or transparent. „Such objects are not so easy to detect with conventional sensors that scan from the side. This is mainly because the front edges of packaged products cannot always be reliably recognised,“ explains Andreas Eberle, Key Account Manager Packaging at Leuze. „The problem manifests itself particularly at high conveyor belt speeds in the form of multiple triggering,“ adds Hermann Sammer. He experiences this above all with irregular shapes such as fish and meat. These are usually individual pieces that do not have exactly the same length and shape. The same applies to plastic packaging for fruit and vegetables.

Putting it through its paces

Sesotec is currently testing the DRT 25C in its technical centre on a wide variety of objects and packaging. The objects travel on the conveyor belt into the Metal detector in. The DRT 25C always detects them at the front edge and along the entire length of the product before they enter the metal detector from above. „The view from above is a great advantage. Irregular shapes are recognised much better. Existing sensor solutions on the market only fulfil this task to a limited extent,“ confirms Sammer. So far, testing experience has been very positive, even in difficult working environments, for example with fast-moving and sometimes highly vibrating conveyor belts.

Positive test results for complex applications

The DRT 25C shows its advantages precisely where conventional sensors that scan from the side reach their limits. In the Sesotec test environment, detailed tests are carried out under „real“ application conditions. For example, Sesotec conveyor belts are deliberately wetted, soiled or stuck together in the test situation, as is often the case in practice due to stuck labels or chocolate residue, for example. „We derive possible product improvements or further developments from these test results,“ says Michael Schafferhans, Technical Sales Consultant at Leuze. Leuze takes feedback from customers and partners very seriously and is actively working on further sensors based on the CAT technology. After all, the ultimate aim is always to provide the customer with the best possible support for their specific application and to make them even more successful.

CAT increases throughput

„The DRT 25C is based on a completely new technology: Contrast Adaptive Teach technology (CAT),“ explains Eberle. The basic idea behind it is simple: the object can change at any time. This is why the sensor does not work with the object, but with its surroundings as a constant reference surface. In packaging technology, this is the conveyor belt. This serves as a teachable reference. As soon as the sensor has learnt the contrast information of the belt („teach“), it simply has to be intelligent enough to adapt this knowledge to a possible change in the environment. This is exactly what CAT technology does. With this reference technology, Leuze has developed a new functional principle in switching sensor technology.

The DRT 25C learns the signal parameters of the conveyor belt at the touch of a button and saves them as „normal zero“. Each object that is transported on the conveyor belt now generates a signal. If this deviates from the zero state, the DRT 25C safely and reliably recognises the object as a „deviation from the reference“. The performance of the device is optimised by selecting the teach level. For example, there is a teach routine for belts that become heavily soiled over time.