The packaging industry is an important part of the printing industry. At this year's drupa there will therefore be a hot spot dedicated to the future of packaging. In Hall 3, Messe Düsseldorf has organised the touchpoint packaging (tpp) together with the European Association of Brand and Packaging Designers epda. This is where participating companies present joint projects, among other things. We took a look around on site.

With 4evergreen, Actega, Adobe, Esko, Heidelberg, Henkel, HP, Huber Group, Hybrid Software Group, Koenig & Bauer, Landa, Leonhard Kurz, Linked2Brands, manroland Goss, Mayr-Melnhof, Mondi, Saueressig, STI, X-Rite and Zecher, the following companies are participating in the programme A total of 20 leading industrial companies on touchpoint packaging. They show exciting projects and innovations in the field of packaging.

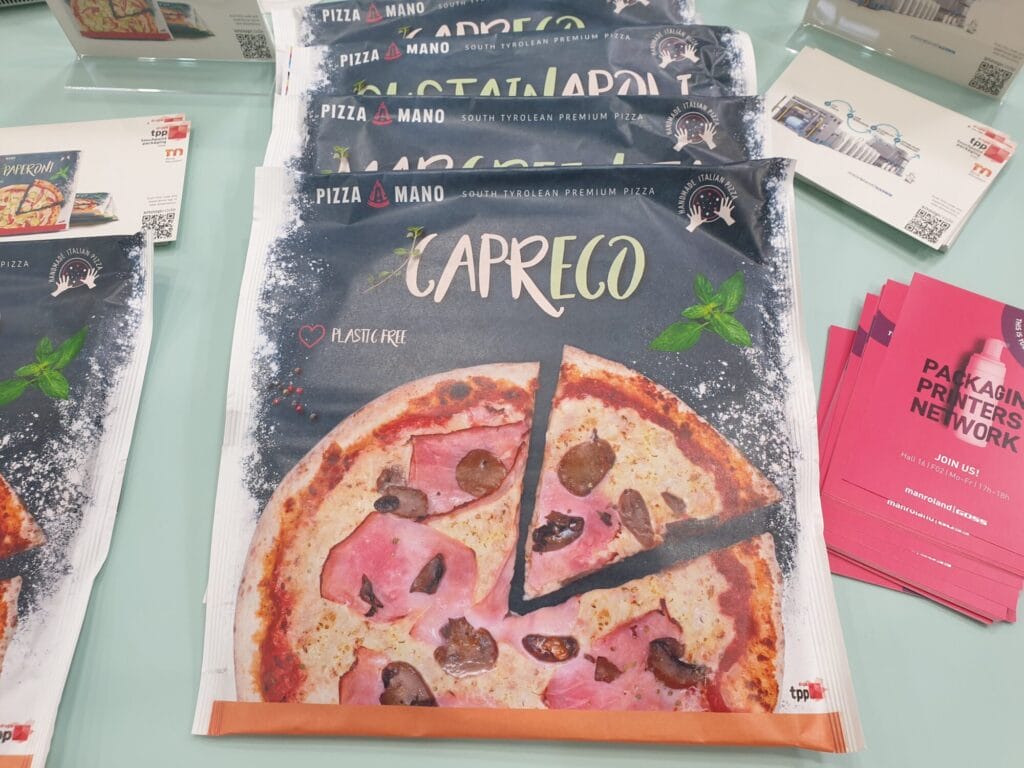

One of these projects is the EcoFlexPack: Four companies, a designer and a South Tyrolean pizza manufacturer have joined forces and developed a sustainable, flexible paper packaging solution. It uses significantly less material and produces up to 80 per cent less CO2 than conventional frozen pizza packaging made of cardboard with plastic inner packaging.

The special recyclable barrier paper comes from Koehler PaperNexPlus Seal Pure MOB is a heat-sealable packaging paper with grease, mineral oil and oxygen barrier and is recyclable in the paper cycle. It was developed at the Weiss Group printed - on a Lithoman IV web offset printing press from manroland Goss. Web offset plates are quick and cost-effective to produce and can be recycled. The specially formulated low-migration inks of the hubergroup for printing food packaging. The packaging design comes from Friederike Dietz and the packaged product is South Tyrol's first handmade frozen pizza from Pizza A Mano from the Puster Valley.

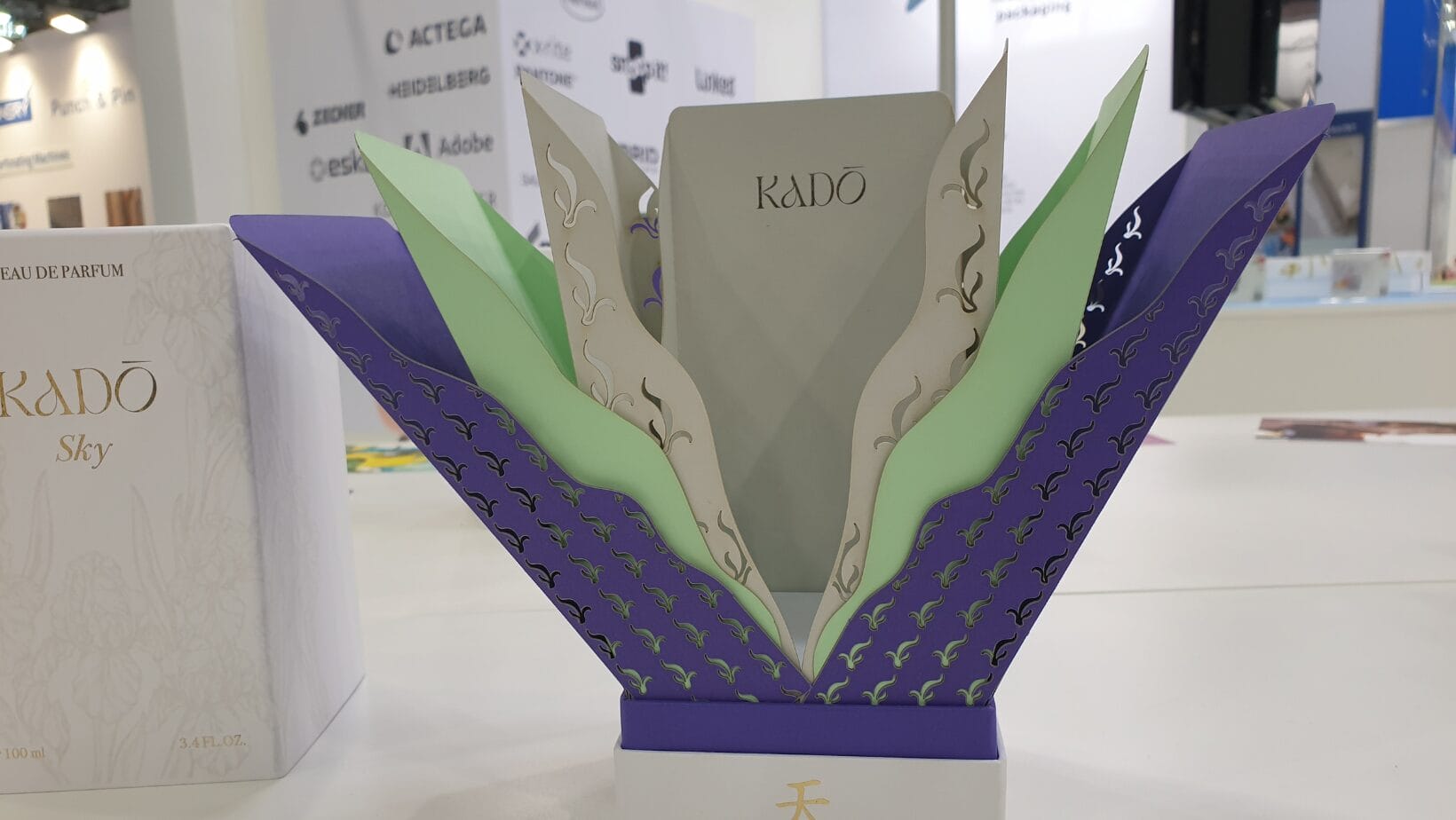

Luxury packaging is the focus of the presentation at touchpoint packaging by Mondi. The company presents its papers for luxury packaging and introduces a project that was realised in Cooperation with the Milan University NABA (Nuova Accademia di Belle Arti). As part of a joint luxury packaging project, students worked with Zoe Truchy and Marlene Langthaler from Mondi to create various designs for the packaging of a luxury perfume bottle using Pergraphica papers.

The result represents the Paper performance in printing, creasing, folding, cutting and special finishing techniques under proof. The Pergraphica range is also certified according to the „Cradle to Cradle Certified“ sustainability standard with the Bronze level, explains Marlene Langthaler at tpp. She will also be showing examples of laser engraving and demonstrating how folding carton blanks are cut and finished from cardboard using a special laser.

Leonhard Kurz presents a project with the Heidelberg Printing Machines in which cold transfer is used for the inline finishing of packaging. This material and energy-saving technology can be used to realise a wide range of packaging design options. The project also includes a recycling programme for the carrier materials used. The „Magical Shapes“ boxes on display were finished inline on a Speedmaster XL 106 v printing press from Heidelberg with the Kurz cold transfer finishing KPS slim 2.0 (patent pending), which is produced on a 50 per cent thinner carrier (6 μm instead of 12 μm). The carrier is removed during the process and can be recycled in Kurz's own recycling plant thanks to the Recosys take-back and recycling system for PET transfer materials.

In a further co-operation project with HP Indigo and the Kurz subsidiary Scribos the Fürth-based finishing expert presents a functionally designed and digitally finished honey packaging with safety aspects. It is intended to show that this type of packaging design can not only increase brand sales, but also save resources and minimise Authenticity of the products through special security features such as the copy-protected QR code Scribos ValiGate. The technology makes it possible to obtain extensive information about product properties, sustainability, ingredients and more by scanning the label with a smartphone.

The HP Indigo 6800, Kurz DM-Jetliner and DM-Maxliner 3D printing and digital finishing machines are used to link the QR code with a 2-factor authentication procedure, so that consumers can receive feedback on the authenticity of the product after scanning. A unique and variable bee distribution on the label becomes visible on the smartphone. Thanks to the Comparison of position, orientation and format of the displayed bees the distribution on the packaging can be used to verify the authenticity of the product. This interactive approach increases security through a „slot machine“-like process that combines digital printing, digital finishing, security (features), track & trace functions and consumer interaction.