Rising costs, labour shortages, increasing sustainability requirements - the demands on the food production industry are constantly growing. At the same time, production must become more flexible, scalable and efficient. Companies are faced with the question: How can resources, material usage and energy consumption be optimised without sacrificing quality or productivity? Answers to these questions can be found at IFFA - at the Multivac Group stand.

As a global solution provider for the processing and packaging of food, the Wolfertschwenden-based company knows the challenges of the industry very well. The company sees itself as a partner for all performance classes, from small businesses to large industrial operations. With its modular solutions and extensive product portfolio, Multivac enables companies to flexibly adapt and expand their production lines in order to position themselves for the future. At IFFA in Frankfurt, Multivac will be addressing the industry's most pressing questions under the motto #Thinkconnected: How can production processes be designed in such a way that they remain flexible and efficient? And how can automation, sustainability and cost-effectiveness be harmonised?

„Technologically, production lines not only have to work reliably, but also increasingly and more deeply connect with the customer's systems. For companies, the ability to control processes based on data, recognise deviations at an early stage and dynamically adjust production parameters is becoming increasingly crucial to success. In addition, further automation of production lines is becoming increasingly important in view of the available labour force. Fully automated and networked line solutions that allow companies to react flexibly to market changes are therefore in demand. Multivac Smart Services specifically utilise machine data for this purpose and process it in a meaningful way. We also have a wide range of innovative solutions in the field of robotics and are working on expanding our portfolio with our own products and with partners.“

Bernd Höpner, Managing Director (CTO) of the Multivac Group

Against this backdrop, the strategic investment issue is also coming more into focus than ever, as Dr Tobias Richter, Managing Director (CSO) of the Multivac Group, knows: „In view of increasing requirements in food production, it is no longer a question of whether to invest, but when and how wisely. Companies that invest in automated and resource-saving production lines now are not just creating short-term efficiency gains. They are laying the foundations for long-term stability and market success.“

Maximum efficiency despite staff shortages

Efficiency in food production is the order of the day - not only to counter the labour shortage, but also because smooth processes are crucial for profitability. The more complex the production processes and the more manual labour involved, the more error-prone the individual production steps are.

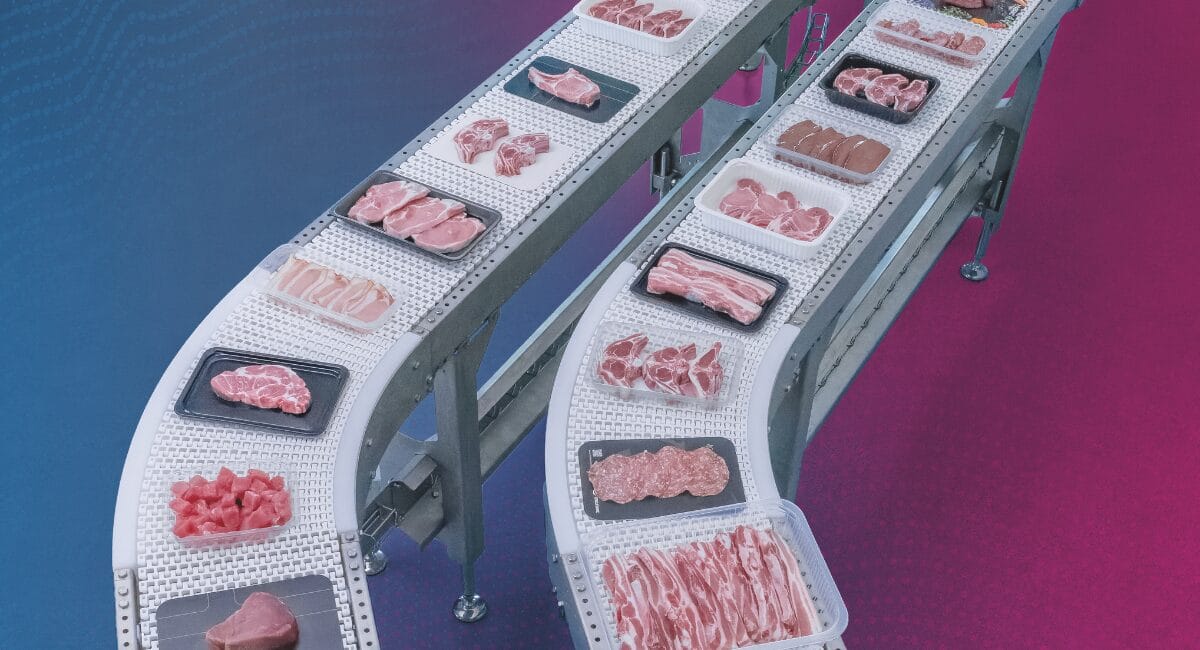

This is where Multivac's solutions, which the company is presenting at the trade fair, come in. Automation, networked machine controls and innovative operating concepts not only optimise personnel deployment and processes, according to the company from Unterallgäu. Errors can also be reduced and unplanned machine downtimes avoided. This helps to significantly increase the output quantity and production times of the lines. For example, in the thermoforming packaging of meat products: While conventional systems evacuate according to predefined time specifications, the RX 4.0 machine relies on sensor technology as standard. It continuously measures relevant parameters, records the current values and compares them with the target values. According to Multivac, the evacuation process runs automatically until the optimum vacuum is reached.

Efficiency is also ensured by Multivac Line Control (MLC), even with fewer personnel: Unlike stand-alone solutions, where each machine is monitored and controlled separately, the MLC provides a standardised control platform that minimises this effort and reduces operating errors. The connectivity functions of the MLC, which enable orders to be transmitted directly to the machines in the line, further simplify the production process. A new function of the MLC, a quick and uncomplicated article change „on the fly“, also contributes to this. Article changes can be carried out directly during operation - without stopping production or time-consuming idling of the line. While the last packs of the previous product are still coming off the conveyor belt at the end of the line, the line automatically switches to the new article section by section: The slicer cuts larger portions, the robot adjusts the insert, the thermoforming packaging machine changes the draw depth for larger packs and the label is automatically printed with the updated product information. This allows companies to optimally utilise their production capacities, emphasises the packaging specialist.

Vision systems can be used to automate pack inspections as well as labelling and print checks, even at high production speeds. Multivac's AI-supported vision systems can classify products according to predefined criteria, check portions and verify pack contents. With automation measures such as these, line efficiency and production capacity can be increased even with limited human resources.

Less material, energy and loss

Another decisive factor is the reduction in the use of resources. Innovative packaging solutions play a central role here.

„Our machines ensure that the use of packaging material is minimised - without compromising product protection or presentation. For example, innovative heating and forming technologies and the optimisation of pack geometry can minimise film thickness without compromising product protection and shelf life. Clever solutions also enable considerable material savings in other areas: The use of so-called full-wrap paper labels instead of cardboard slipcases reduces the amount of material used to a minimum in many cases, despite a comparable look and feel. By spraying tiny amounts of vegetable oils as a release agent between slices of meat, such as raw ham, the usual use of release film becomes completely superfluous. All of this not only reduces material costs, but also helps companies to fulfil the increasing requirements for sustainable production.“

Bernd Höpner, Managing Director (CTO) of the Multivac Group

Modern technology also helps to noticeably reduce both environmental impact and operating costs when it comes to energy consumption. With the help of Multivac's Consumption Monitoring, the consumption of compressed air, cooling media, energy or packaging materials is recorded across the entire line and analysed in real time. This enables creeping excess consumption to be recognised at an early stage. Where sliced products are traditionally frozen with high energy consumption for processing, the strength of slicer technology becomes apparent: thanks to the optimised slicing system, precise slicing is possible at higher product temperatures. Less cooling requirement means less energy consumption.

In addition to materials and energy, the product itself is also at the centre of increasing efficiency. The aim is to maximise product yield and minimise give-away. In volumetric portioning of meat, a process for maximising yield in which Multivac subsidiary TVI is a leader, the meat is pressed into shape from several sides during cutting. The process is monitored and adjusted by integrated measuring and control systems. The „Line Give-away Analysis“ can be used to determine exactly how much yield was achieved from the raw material and what influence manual corrections had on the „give-away“. According to Multivac, this offers a completely new level of transparency.

Dr Tobias Richter explains: „Rising costs, labour shortages and strict sustainability requirements mean that the food industry needs solutions that focus on all aspects of the value chain - from raw material processing to packaging. Smart processing and packaging technologies are real competitive factors here: not only do they help to sustainably optimise machine operation, they also enable agile production that can be adapted to the growing demands of a changing market.“

IFFA 2025: Hall 12.1, Stand A41