Busch Vacuum Solutions, a leading global supplier of vacuum pumps and systems, will present its innovative vacuum solutions for the process industry at Achema 2024, demonstrating its commitment to sustainable technologies and environmental protection.

In chemical and pharmaceutical process engineering, vacuum plays a decisive role in accelerating reactions, protecting materials, cleanly separating individual substances and enabling economical processes. Busch Vacuum Solutions offers Customised and reliable vacuum technology for a variety of processes in these industries.

Flexibility for sensitive processes

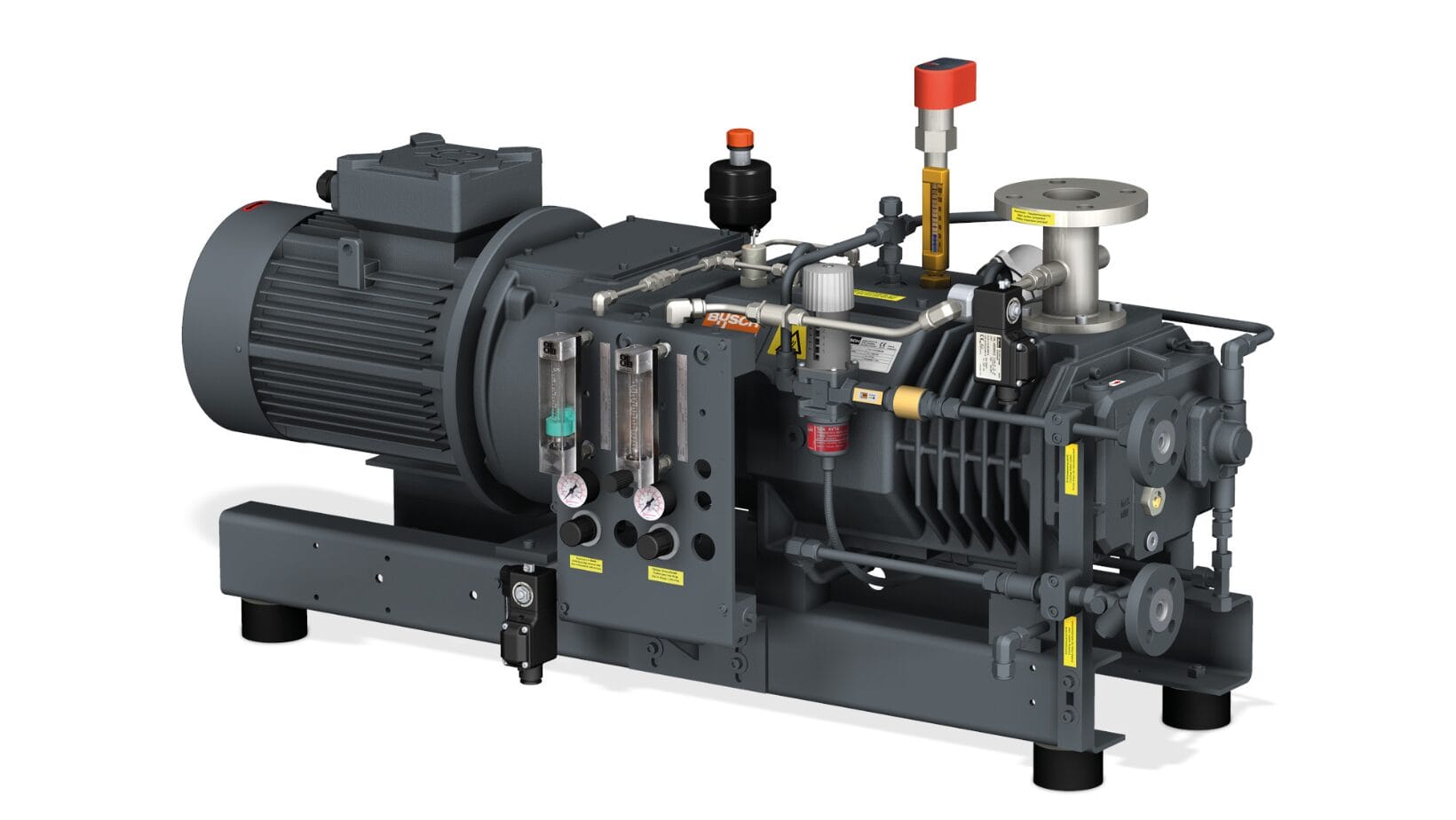

The COBRA NC 0100 B screw vacuum pump is a versatile solution for pumping sensitive and explosive gases or vapours. Its design enables safe operation at ultimate pressures of 0.01 hPa (mbar) without the risk of contamination by operating fluids. Their modern screw technology, including the patented self-balancing screws, achieves high compression efficiency and ensures reliable operational safety. The flexibility of COBRA screw vacuum pumps enables customised configuration, which can be perfectly adapted to the requirements of different processes. Their speed control and oil- and contact-free operation make them particularly environmentally friendly and energy-efficient.

The DOLPHIN LX 0430 liquid ring vacuum pump sets new standards in terms of efficiency and reliability. Even demanding applications such as the Evacuation of saturated gases and vapours is possible without any problems. The operating fluid is usually water or, if required by the process conditions, another fluid. Thanks to its sealing concept with optimised Viton or FFKM seals, it is ideally suited for use in chemical and pharmaceutical process engineering.

Efficiency for a greener future

The MINK MV 0080 D is a powerful dry claw vacuum pump that is suitable for a wide range of industrial applications. Thanks to its high efficiency and reliability, it helps companies to reduce their ecological footprint.

Busch's dense service network guarantees smooth processes and efficient operation in the process industry. Supported by intelligent IoT solutions, downtimes in production can be minimised even further. For high operational safety in potentially explosive atmospheres, Busch offers the ATEX check. Specially qualified and certified service technicians from Busch thoroughly inspect and document all ATEX-relevant components of the vacuum pump, blower or compressor.

Source: Busch Vacuum Solutions

Busch Vacuum Solutions at Achema 2024: Hall 8, Stand H38