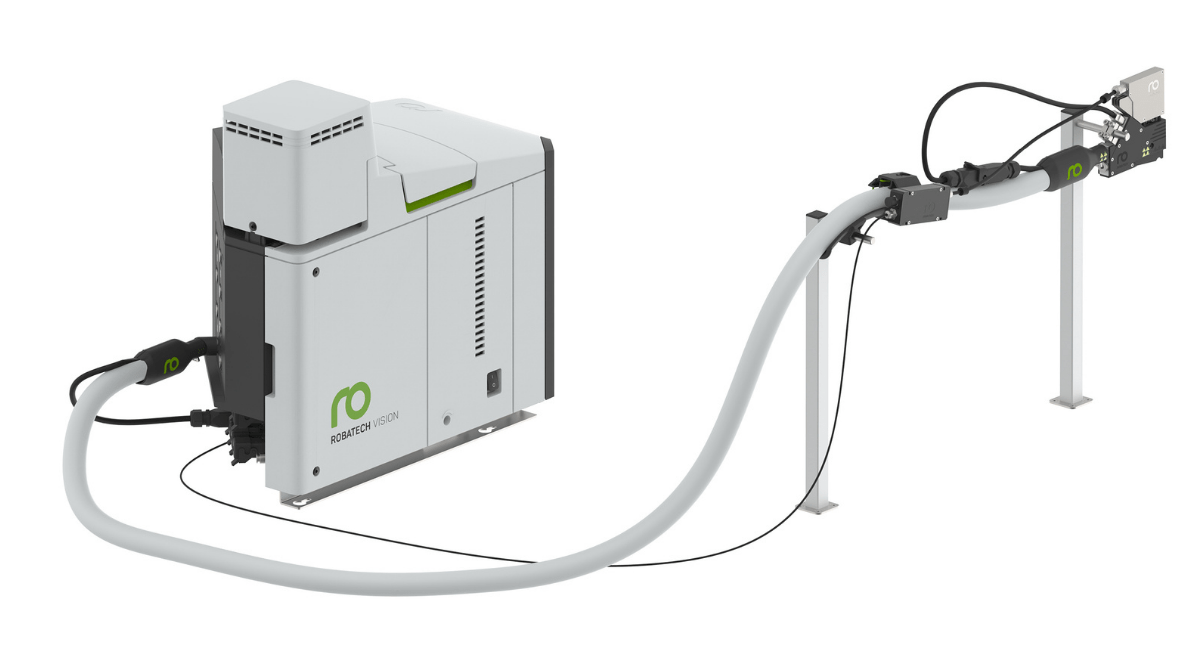

With Vision, Robatech has developed an energy-efficient melter with a space-saving design and new features for safe product bonding and favourable operation.

Vision can melt even demanding thermoplastic hotmelt adhesives gently, keeps the adhesive viscosity constant and delivers hotmelt to the application head with stable pressure. The reliability in precise adhesive application, the especially for the bonding of primary packaging is thus significantly increased. Compared to the previous Concept model, Vision requires 20 per cent less energy.

"Vision is a completely new melter that opens up a new dimension in bonding. The adhesive application is as repeatable and even as a Swiss watch." Martin SpalingerDirector Strategic Marketing & Innovation

Smart Terminal takes the strain off operating personnel

With the Smart Terminal Robatech a new feature on the melter market. Current operating and status information is displayed in changing colours via an LED bar on the appliance. The advantage: Even From a distance, the operating personnel can recognise whether the gluing process is running smoothly or adhesive needs to be refilled, for example. The display of the current pump pressure, status codes and four function buttons facilitate operation and quick intervention.

Flexible melter

Vision offers machine builders many possibilities. The melter can be installed lengthways or crossways: it can be operated remotely or via the optional touch display, which is mounted on the front or side. About the innovative 45-degree FlexPort connection surface heating hoses can be connected at different angles to save space. This gives customers the flexibility to position Vision at the shortest possible distance from the application heads and thus keep the heated hose length short. The Robatech Control System also offers open interfaces and standardised fieldbus protocols for easy integration into overall systems.

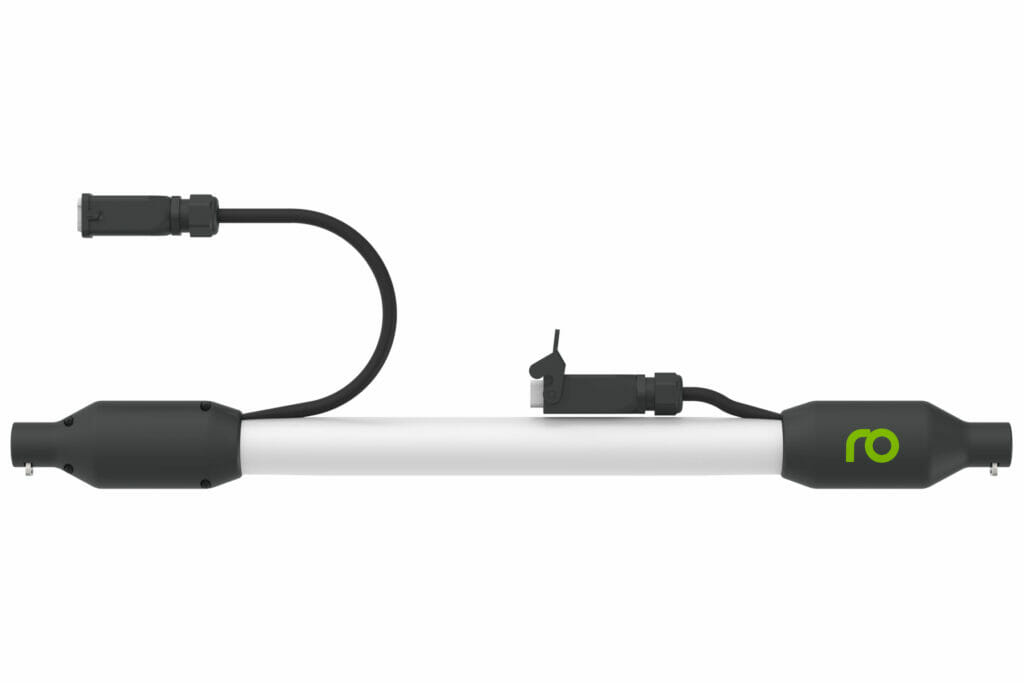

New heated hose for precise adhesive application

The new Performa heated hose is suitable for viscosities from 100 to 20,000 mPas and requires up to 45 per cent less energy than conventional heated hoses such as Robatech's Enduro. With the development of the PrimeConnect plug-in coupling, Robatech has achieved several goals at once: customers can use Performa Connect quickly and error-free without special tools using the plug-and-play method. In addition, the adhesive viscosity also remains constant at the connection points to the melter and application head. PrimeConnect is fully insulated and eliminates the usual cold bridges.

Robatech also fulfils the promise of high backwards compatibility with its latest products. Vision is compatible with heated hoses and application heads manufactured up to 2000. Performa can be used with Concept series melters in combination with Enduro heated hoses. This enables customers to successively retrofit their existing systems with energy-efficient system components and optimise the adhesive application quality.

[infotext icon]Die Robatech-Gruppe mit Hauptsitz im schweizerischen Muri ist ein weltweit führender Hersteller von innovativen und nachhaltigen Klebstoff-Auftragslösungen für den industriellen Heissleim- und Kaltleimauftrag. Seit 1975 produziert und liefert Robatech hochwertige Steuerungen, Auftragsköpfe, Schmelz- und Dosiersysteme.[/infotext]

Source: Robatech