Engel is showcasing the automated production of caps at drinktec in Munich. The focus of the fully automated production cell is the all-electric e-cap 380 injection moulding machine.

The produced Caps from United Caps correspond to a standard widely used in the beverage industry. The notch of the safety ring - also known as the guarantee ring - is created in the mould and then folded in downstream on the underside. When the cap is opened for the first time, the ring separates from the cap body and clearly indicates whether the product has already been opened.

Manufactured in a 48-cavity mould with a cycle time of four seconds. In the fully automated production cell integrated into the Engel CC300 control system, the 38-metre caps are transported via a cooling conveyor belt with waterfall sorting to the folding station, where the lower edge of the ring is bent inwards - for a secure hold on the bottle neck.

Fully electric and efficient

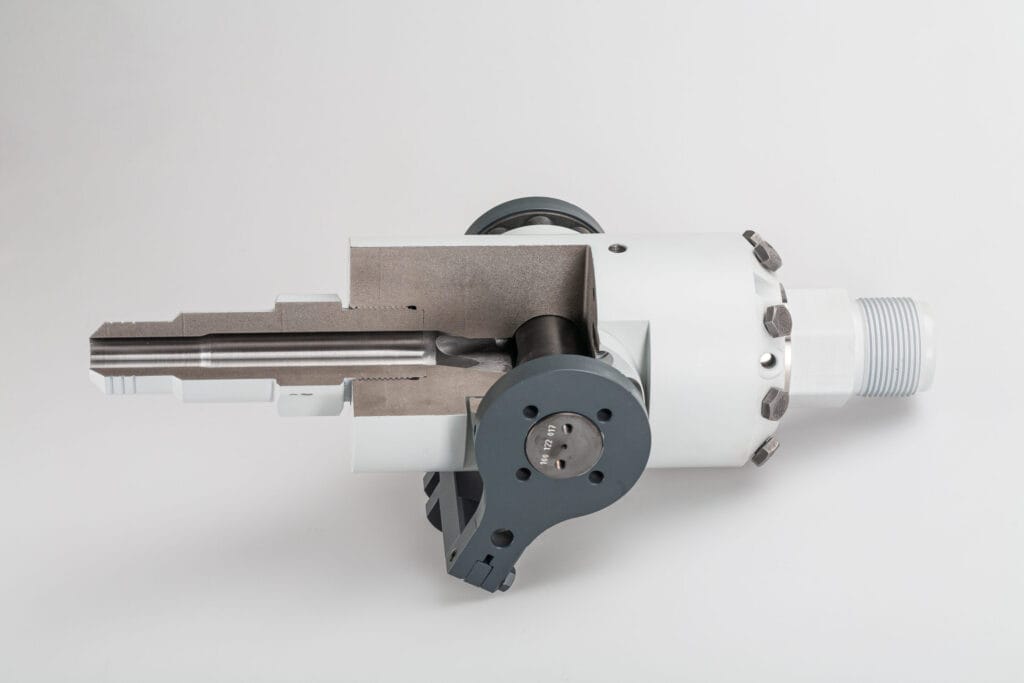

The e-cap machine series was specially designed for the production of beverage closures. It impresses with short cycle times, high reproducibility and low energy consumption. The e-cap machines can be used flexibly with different clamping force sizes and a compact design and are designed for continuous operation under the highest demands.

The e-cap is fitted as standard equipped with the Engel Packaging Package, which significantly increases the performance of the machine. This includes a high-clamping unit that is optimised for extremely short cycle times, a reinforced, higher moving platen, high-performance machine shoes for a stable and quiet stand and powerful high-performance injection units.

Digital support

Thanks to digital assistance systems such as iQ motion control and iQ weight control Cycle times automatically optimised and fluctuations in shot weight compensated for. The new injection unit 2465, which increases the injection speed by almost 67 per cent and is particularly easy to maintain, is already being used in the trade fair exhibit. In addition, the new e-flomo one cooling water distributor ensures constant cooling conditions and reduced waste.

Engel is one of the world's leading manufacturers of injection moulding machines for the production of caps and closures. With a broad machine portfolio, outstanding automation expertise and many years of experience in the industry, the company realises customised solutions for both for standard caps as well as for demanding special applications such as slit-and-folded caps.

Source: Angels

Engel at drinktec 2025: Hall C6, Stand 140