The requirements for transporting temperature-sensitive products are high, especially in the pharmaceutical industry, as medicines, diagnostics and vaccines have to be moved around the world under constant temperature conditions. Eutecma GmbH from Mannheim has specialised in the cold chain and is setting new standards with modular, reusable packaging solutions.

In temperature-controlled logistics, every detail counts - from transport safety to cost efficiency and sustainability. Eutecma has specialised in precisely this interface with modular, reusable and recyclable refrigeration solutions. „Since we were founded in 2008, we have concentrated 100 per cent on the cold chain,“ says Florian Zeilfelder, who manages the company together with Markus Baumgärtner.

„Three aspects are crucial for us: we get goods safely from A to B within the required temperature corridor, we consider the costs along the entire supply chain, including air freight logistics and handling at the customer's premises, and we focus on sustainability.“

Florian Zeilfelder, Managing Director

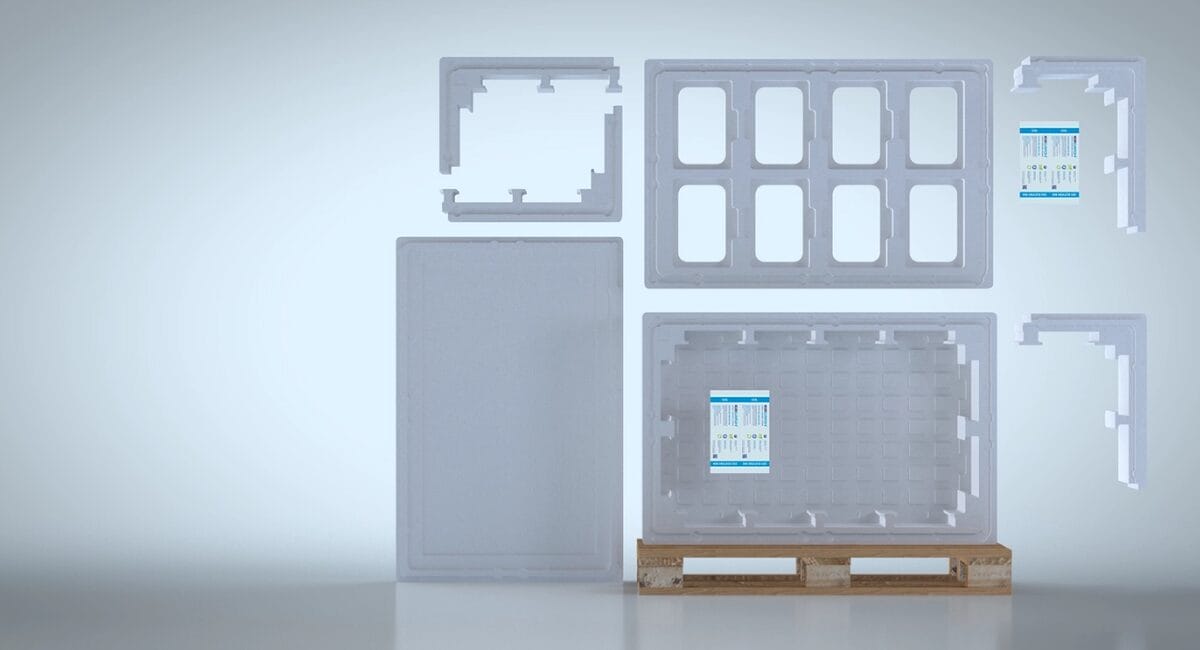

Reusable instead of disposable: the modular approach

Eutecma has developed a modular packaging system made of EPS (expanded polystyrene) for this purpose. The system packaging boxes in the Protect series are designed in such a way that they can be configured with a minimum number of different components for a maximum number of required transport sizes of between four and 1,588 litres. The passive cooling systems guarantee stable temperature control over a period of up to 120 hours. This is made possible by the Icecatch cooling elements, which cover the range from ambient (15 to 25 °C) to cool (2 to 8 °C) to frozen (-25 to -15 °C) and are compatible with all boxes thanks to their standardised format. „Our Protect boxes are equipped with slots for the cooling elements and can be fitted for all relevant temperature corridors.“ This standardisation not only saves material and weight, but also reduces costs, especially for air freight, while significantly reducing CO₂ emissions.

A specially developed software tool called Icecatch-Protect Guide also supports users during return shipment or qualified reuse by making it easy to select the configuration. The programme calculates the ideal box and coolant combination based on parameters such as transport duration, temperature range and expected outside temperatures. The result is a precise, cost-efficient and safe packaging solution.

Refreshment Centre: the washing line for the cold chain

The entire process of the resfreshment centres is documented using RFID chips and cloud-based systems, including the calculation of individual CO₂ savings per box. The result: around 97 per cent less CO₂ emissions compared to new production. Florian Zeilfelder: „Of course, you also save 100 per cent material.“

Eutecma already operates two such plants, one near its headquarters in Ludwigshafen and another in Springfield (Ohio, USA). Further sites are being planned. The aim is to establish a global network for the closed EPS material cycle of the Protect boxes and for Eutecma's customised cooling elements.

Strong partners for the next phase of growth

In June 2025, the Mannheim-based company received strategic support: US investor Great Point Partners (GPP), which specialises in the healthcare sector, acquired a stake in Eutecma. Together, the aim is to accelerate the international rollout of sustainable cold chain systems. „Our collaboration with GPP gives us the opportunity to scale our solutions globally, particularly in the USA and other important markets,“ says Zeilfelder.

At the same time, Eutecma is strengthening its innovative strength through strategic partnerships in the field of digital cold chain monitoring. The integration of sensors and data loggers enables real-time monitoring of the entire supply chain. Packaging and data are thus linked to form an intelligent overall system that offers maximum transparency and security.