In the 1950s, the development of plastics technology made it possible to use polymers in the packaging sector. A decade later, they were already able to compete with other packaging materials in the first competitions. Since then, the award-winning objects have made it possible to follow the advance of these versatile packaging materials into our daily lives.

According to the German Federal Statistical Office, plastic packaging is currently (as of 2015) one of the leading categories, accounting for over 40 per cent of the value of packaging. The requirements for this packaging group are not only the fulfilment of the Main tasks product protection, rationalisation, information and advertising. Modern packaging has a memory, reminds us of expiry dates and the degree of ripeness of food, can be heated in the microwave and is indispensable in the healthcare sector thanks to its functional design, compliance with hygiene regulations and protection against counterfeiting. Integrated codes and RFID chips make logistics easier. They speak to all our senses to advertise the contents. In addition, plastic packaging must also comply with legal requirements, be cost-effective and fulfil the ecological problems place.

Excellent packaging as a development indicator

The award-winning plastic packaging reflects the different focal points of the plastics industry. In the 1960s and 1970s, there were numerous awards for barrels, canisters, pallets, bottle crates and other products. Reusable transport packaging made of plastic. Although polymers were initially seen primarily as a substitute for metal, wood and glass, they soon won over customers with their outstanding properties and manufacturing advantages. This was confirmed by the transport packaging and cushioning elements that won prizes in the first German packaging competitions, such as the „innovative plastic canister for antifreeze with a secure closure and easily stackable shape submitted by Farbwerke Hoechst in 1963 and BASF's wine bottle packaging made of PS rigid foam.

In the 1990s, with the introduction of the Packaging Ordinance and the Green Dot, the focus was on the Reduction of the operating weight of the packaging. Plastics whose licence fees placed a particularly heavy burden on the industry as a result of difficulties in recycling were awarded a prize if they were assigned to the „Lightweighting“, extended their service life at the customer's premises as a storage container, or were made more durable through the use of Recyclate in transport packaging. There was also demand for packaging with tighter closures and improved removal options or packaging that was suitable for the Transport of dangerous goods such as the multi-award-winning WERIT plastic containers for liquid hazardous goods.

The latest requirements for plastic packaging

More recently, the focus has been on Sustainability, environmental protection, better Handling properties and effective advertising design. Food packaging made from technologically outstanding film composites also makes a significant contribution to the Environmental protection They contribute to a longer shelf life of the product and thus reduce the mountain of almost 70 million tonnes of food losses that occur in the EU every year, according to statistics from the Food and Agriculture Organisation of the United Nations (FAO). One example of this is the vegetable and fruit packaging with intelligent micro-perforation in the multi-layer film barrier from Mexico, which received the German Packaging Award (DVP) in 2016.

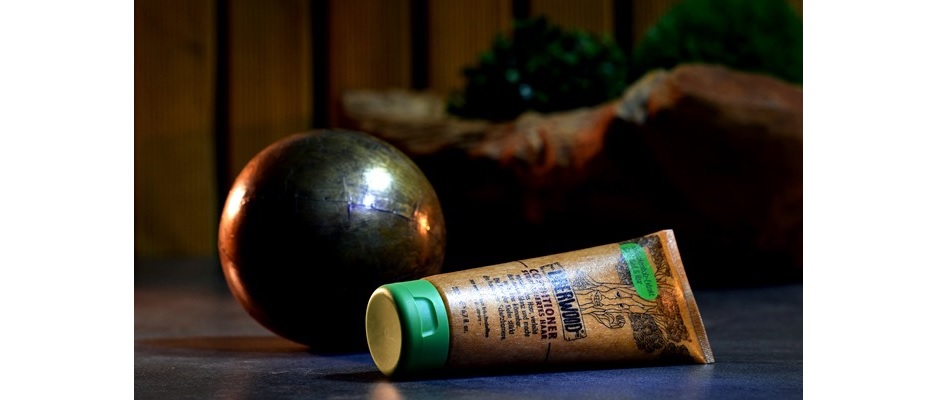

A successful combination of plastic and renewable raw materials is the Überwood tube from TU-Plast in Hungary, which was honoured as Tube of the Year 2016. This PE tube has a wood-based material content of over 25 percent and stands out with its colouring and surface texture, where you can almost feel and smell the wood.

Plastic packaging has also proven to be an indispensable aid in the medical sector, as demonstrated by the syringe applicator from Gaplast GmbH, which also won the DVP in 2016. It makes local anaesthesia superfluous thanks to the sterile, targeted subcutaneous application of long-term medication.