At the end of April 2020, Sonotronic Nagel developed an ultrasonic machine concept for manual workstations for the production of mouth and nose protection masks made of non-woven textiles, which is inexpensive, can be delivered quickly and is ready for immediate use.

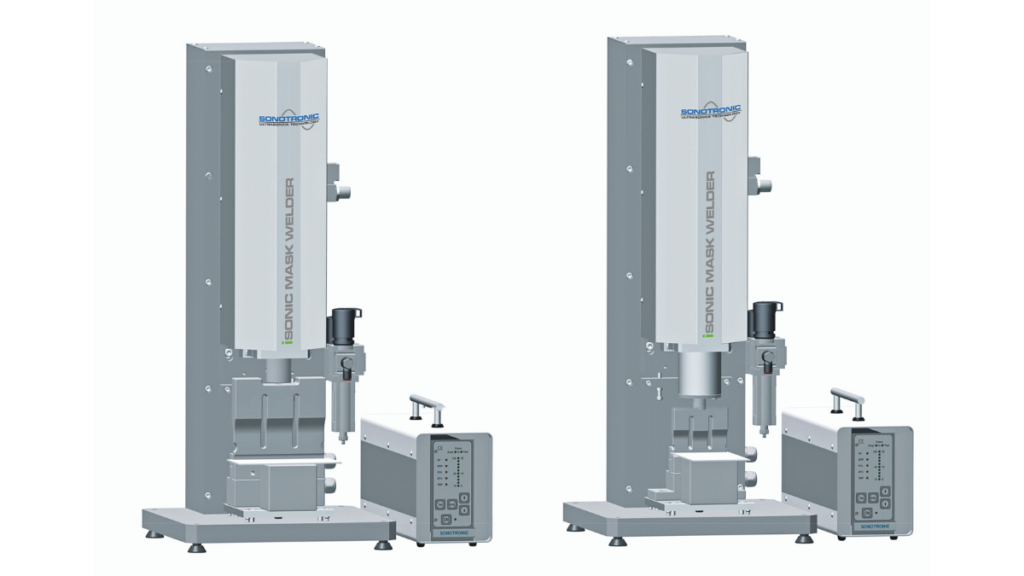

The solution consists of the iSONIC Mask Welder Duo, one 20 kHz and one 35 kHz Ultrasonic standard machine. The concept focusses on simple handling, short cycle times and user-friendliness - and Mouth and nose protection masks can be produced without prior knowledge.

The Non-woven mask blank is manually inserted into the machine for ultrasonic welding. is inserted. Pressing the foot switch then triggers the automatic welding process, which is controlled pneumatically. For production, the operator needs Only four ultrasonic welds. Including the small steps such as folding the fleece edge by hand, a mouth and nose protection mask can be produced in around 18 seconds. become.

With this machine concept, Sonotronic has responded to the strong demand for the production of face and nose masks and has recently been recognised by the Federal Office of Civil Protection and Disaster Assistance. Listed as an operator of critical infrastructures (KRITIS). All ultrasonic components are manufactured to high quality standards and manufactured one hundred per cent at the Karlsbad site. This guarantees high machine availability, attractive prices and very short delivery times.

For the classic production of face masks as well as for the manufacture of FFP masks and hygiene and protective equipment, the use of ultrasonic moulds is essential. In addition to the economic aspect, this is also an environmentally friendly solution.

Ultrasonic systems or ultrasonic roll seam units can be integrated into all semi-automatic or fully automatic production lines that process synthetic materials. Continuous ultrasonic welding or cutting and sealing (Cut & Seal) can be used. Existing systems can also be optimised with ultrasonic modules in order to increase automation within the processes.

[infotext icon]SONOTRONIC Nagel GmbH is the market leader in special ultrasonic machine construction for the automotive industry. In addition, high-tech ultrasonic systems for the packaging, food, textile, medical and environmental industries are developed and produced at the Karlsbad site. The long-established company employs over 350 people at its headquarters in Karlsbad and its subsidiaries in Spain and the USA.Source: Sonotronic