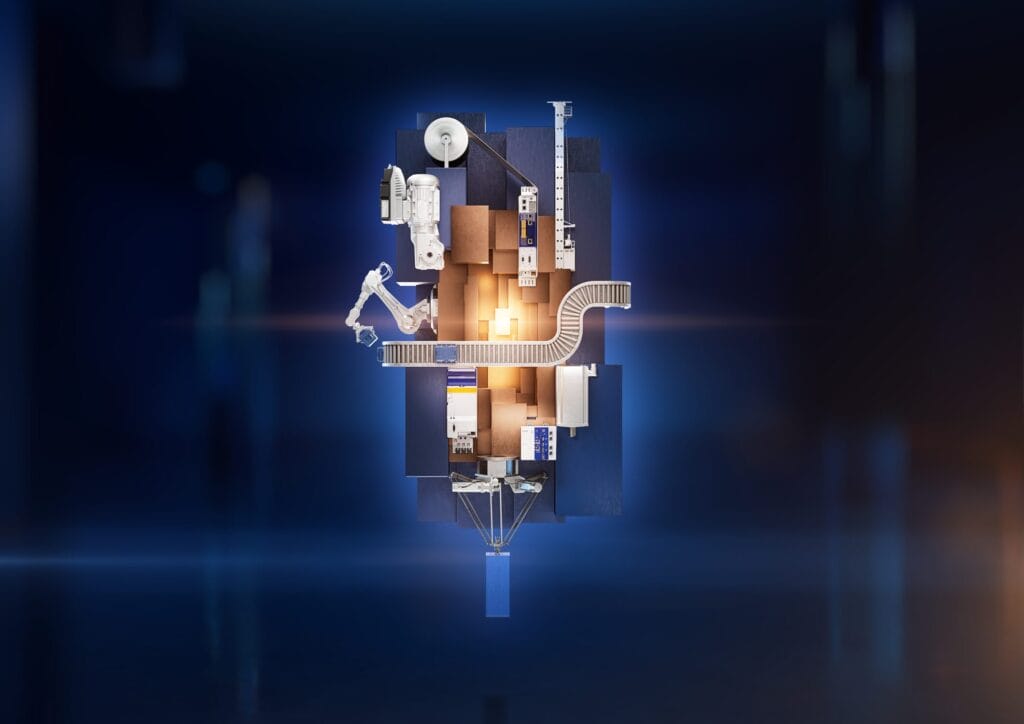

At SPS in Nuremberg, Lenze will be showcasing solutions that enable OEMs to sustainably increase their productivity and efficiency despite a lack of resources, IT expertise, high costs and pressure to innovate. Visitors will experience the new Lenze Nupano Suite, a new generation of controllers and the Edge series, as well as the new m550 Motor Drive System.

The Lenze Nupano Suite extends over the entire life cycle of the machine and provides answers to the megatrends of energy efficiency, AI and the shortage of skilled labour in development. It helps customers to significantly reduce their engineering times, fulfil cyber security requirements and develop digital revenue models.

During the planning phase, users have full access to planning and design tools such as the Easy System Designer. The wizard supports the planning of everything from single-axis applications to complex machine solutions. Lenze's domain knowledge and calculation models based on experience enable Energy-efficient drive systems. The machine process is modularised, the user can select solution elements or use wizards. Lenze also supplies the Connection to digital services such as CAD, EPLAN and supports the user in creating a PLC template.

The build phase is all about engineering, commissioning and series production. Machine builders can a ready-made software framework to integrate, test and scale ready-made software modules. Commissioning takes place virtually, which shortens the development time. Lenze focuses on parallelising the development of mechanical and electrical software. For the deployment of IT software, the company supplies a tool that simply and efficiently installs and manages containerised software on series machines.

During the operating phase, the machine manufacturer supports its customers in the operation of the machine. Thanks to the centralised machine management in the Lenze Nupano Suite, they can offer their customers service ticketing applications for machines or add anomaly detections, for example. At the same time, the user gains Full transparency about the software versions on his machines.

IT-inside controller and edge device series

Lenze also provides a Preview of a new machine controller. It can take on control and IT tasks and therefore fits in perfectly with the platform strategy. In Nuremberg, Lenze will also be presenting an edge device with a pre-installed app management tool for scaling IT outside or independently of the control system in machines. This allows the customer to transfer out-of-the-box IT applications to the device.

There is also news from the drive technology sector: Lenze presents an innovative motor system m550 - a combination of g500 geared motor, i550 or i650 frequency inverter and perfectly harmonised software. The Motor Drive System in efficiency classes IE5/IE7 is one of the most energy-efficient systems on the market. The hardware is seamlessly integrated into the Lenze Nupano Suite with the EASY System Designer. The software in the application makes the synchronous motor as easy to use as an asynchronous motor. Added value for everyone who designs and operates conveyor systems.

Source: Lenze

Lenze at the SPS 2024: Hall 7, Stand 391