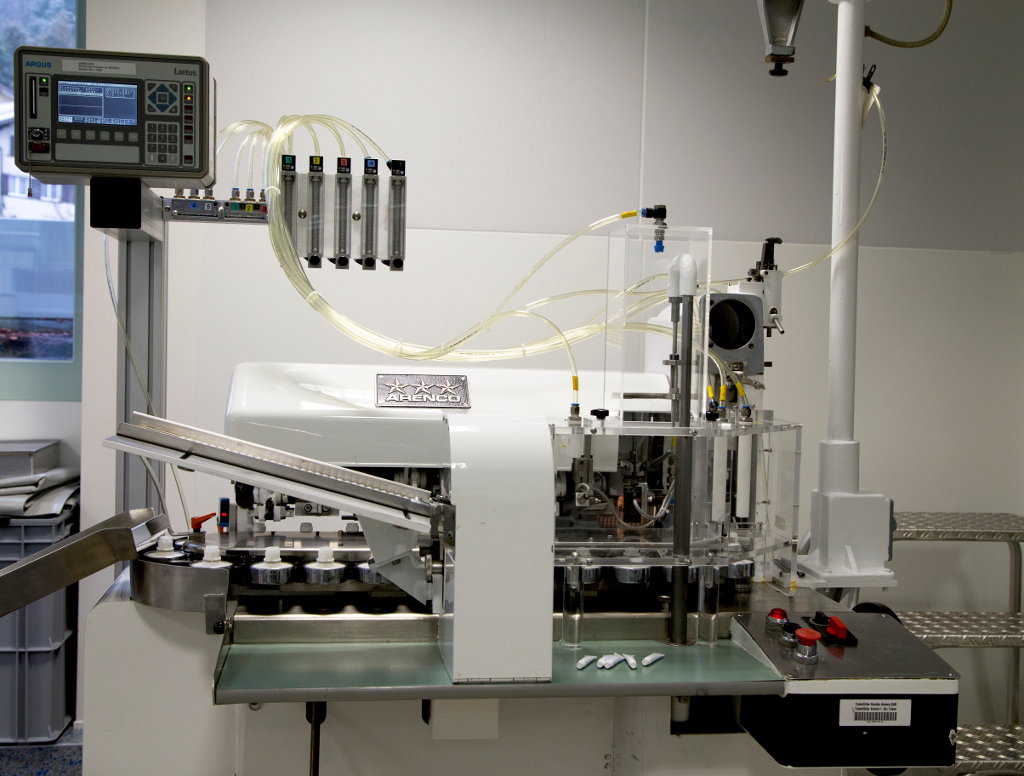

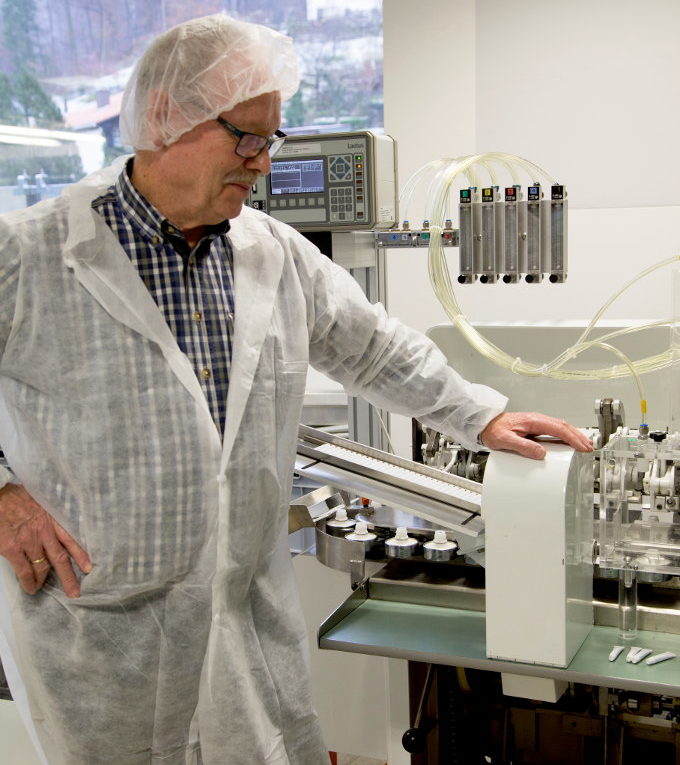

At the end of November 2017, Bernhard Leusing, service technician at NORDEN Maschinen GmbH, Ostfildern-Kemnat, travelled to Glaropharm AG in Mitlödi (near Glarus, Switzerland) to check that everything was in order: The ARENCO GAB tube filler has been reliably performing its tasks there since 1986 and continues to meet the highest quality standards.

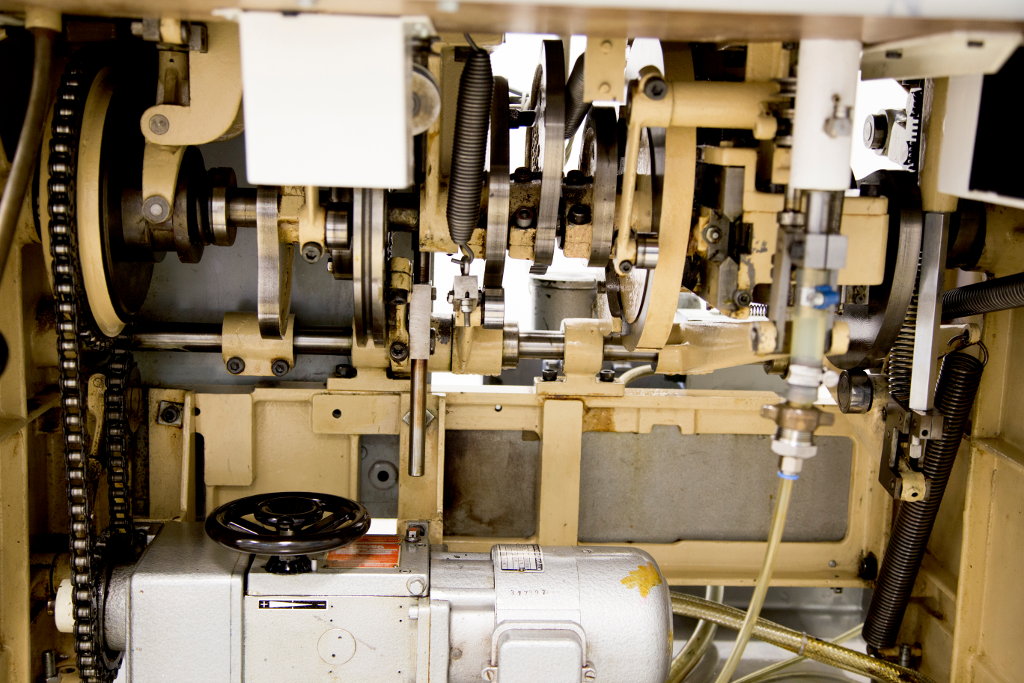

The Tube filling and sealing machine was delivered to Grünenthal Pharma AG in Mitlödi in 1975. It dates back to the time before the ARENCO tube machine division became today's NORDEN Machinery AB. The technology was primarily designed for handling metal tubes, but can also weld PE tubes with additional units. It can also be used to fill cans, vials and ampoules.

The machine type is used for filling Toothpaste, skin, shaving or shoe polish, Colours, Adhesives, various Food such as caviar, meat and fish pastes, tomato paste, mustard and mayonnaise, and Cosmetics and Medication for use.

Single, double and saddle seams are available as tube closure options. In this particular case, the saddle seam is used, which is particularly demanding. This enables coding on both sides.

Absolutely clean tubes

Thanks to the special design of the pump and the progressive filling system, it is guaranteed that no product enters the pump. Sealing folds can be reached. The tube is automatically raised to the filling mouthpiece, which almost reaches the bottom (the cap end) of the tube before filling begins. The rest of the filling adapts exactly to the tube being lowered. The consistency of the paste is not changed. There is no mixing of air with the filling material during the filling process.

The filling mechanism is easily adjustable to different volumes. The correct filling quantity is guaranteed by adjusting the pump accordingly. The Easy cleaning of the pump and the quick format change make it easy to change the filling material and tube size. Operation is made easier because a large number of tube holders are accessible for inserting empty tubes.

The machine impresses with maximum reliability in production and continues to meet the highest quality standards. Even today, in the age of digitalisation and Industry 4.0.

Use at Glaropharm

When Bernhard Leusing arrives in Mitlödi, a gel is being filled into 2 ml aluminium tubes, which is used to treat certain types of cancer. The products, such as gels and creams, are filled in a corresponding aluminium tube. Clean room zone in a capacity range of 10 to 60 pieces per minute, depending on the consistency of the filling product. Since 2011, the machine has only been used for 2-gram and 10-gram tubes.

The tube filling and sealing machine also fulfils the ever more stringent requirements for hygiene and traceability. All of the Filling material All parts that come into contact with the device are made of non-corrosive material and can be easily removed for cleaning. The authorities (Cantonal Medicines Control, FDA - Food and Drug Administration) regularly check that the specifications are fully complied with in accordance with the GMP guidelines.

Quality and reliability

Silvia Knobel has been working on the machine for more than 20 years. She cannot remember any unplanned interruptions to production. The machine is equipped with a pump and corresponding format parts, the dimensions of which correspond to the tube dimensions used by the customer. The tubes are sealed step by step in several stages. Folding stations executed. On request, a code consisting of letters and/or groups of numbers can be embossed into the closure seam. The alignment of the tubes is supported by a photoelectric arrangement. For semi-automatic operation, there is a Tube feeder. This is followed by filling, tube alignment and then the fold and ejection of the finished tube.

In the last four years, the annual production volume has been between 80,000 and 150,000 tubes.

Glaropharm AG is one of the five production sites that belong to the Frike Group holding company. While pharmaceutical products are manufactured in Millödi, the other holding locations specialise in products for the chemicals, cosmetics and aerosols sectors.

Yusuf Avci, packaging manager at Glaropharm, reports that customers have very high quality requirements, which can only be met with perfectly aligned tubes and a perfect saddle fold, among other things.

The highly qualified staff are familiar with the demanding legal requirements. Consistent and uncompromising implementation guarantees impeccable quality and product safety. The site is GMP-certified by Swissmedic (Swiss Medicines Agency). Plant manager Markus Häner explains that many well-known companies are among Glaropharm AG's customers.

[infotext icon]Norden Maschinen GmbH has developed into the world's leading manufacturer of tube filling and packaging machines. Every year, more than 150 machines are delivered all over the world. The feedback from the more than 5,000 machines installed and the close communication with its customers provides the company with the expertise it needs to further develop its products[/infotext].