Metsä Board has developed a new concept for gift packaging just in time for Christmas. The packaging is made from lightweight virgin fibre paperboard, fine flute, and can save material and CO2 compared to conventional solid board packaging.

A few years ago, the team at the Excellence Centre of Metsä Board in Äänekoski, Finland, started work on the new alternative. „We wanted to offer the same experience as current solutions. To do this, we developed a Cardboard further developed, which is strong and stable and at the same time more lightweight and environmentally friendly,“ explains Ilkka Harju, Packaging Services Director at Metsä Board. As the best solution proved to be the fine wave, which has a much smaller and lower flute size than conventional corrugated board solutions.

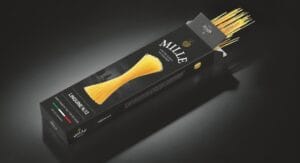

The new packaging consists of a separate base and lid, both made from fine flute. It is also designed to be production-efficient from start to finish and is suitable for the Mass production on existing production lines is suitable - without the need for major conversions. The top layer can consist of both uncoated white kraftliner and coated white kraftliner. The latter gives the packaging the best printing properties. According to Harju the new gift packaging solution is particularly suitable for cosmetics, chocolate, drinks and other premium products:

„Cosmetics are probably the most important application area. However, the material can also be easily customised for other end uses to create unique packaging solutions.“

The new lightweight solution also uses less material. The company's Sustainability Services team compared the new packaging with solid board boxes made from recycled, fibre-based material and found that the Concept with the fine wave up to 50 per cent lighter is. „Thanks to its light weight, the new packaging solution can therefore help our customers achieve their carbon reduction targets,“ adds Harju.

The cradle-to-gate footprint of the new solution - which takes into account the individual stages of the value chain from raw material extraction to leaving the cartonboard mill - was also calculated and is 59 per cent lower than with conventional solutions. And that's not all: „Since the packaging solution No harmful adhesives or other plastic laminates recycling becomes much more efficient,“ summarises Harju.

Source: Metsä Board

More news on cartonboard and fibre-based packaging

From OEM to independent supplier in cartoning machine construction

Metsä Board optimises folding boxboard for European markets

Waterscoring for precise folding carton gluing

Metsä Board plans Packaging Design Studio in Milan