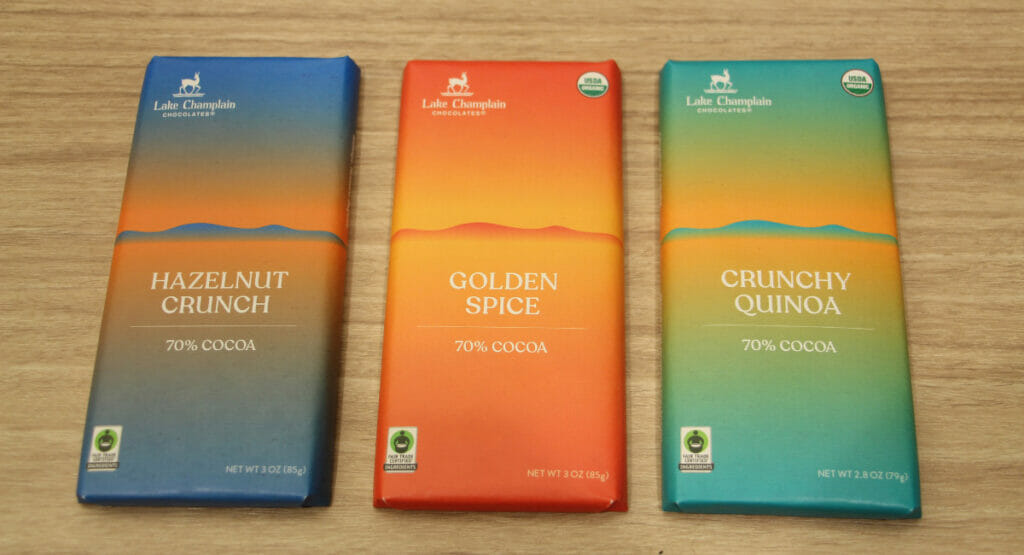

Fine chocolate specialities are the passion of Lake Champlain Chocolates. For almost 40 years, the North American family business has been using regional ingredients for its products, combining creativity, craftsmanship and efficiency. The manufacturer relies on the system solution from Loesch Verpackungstechnik for the packaging of chocolate bars.

The production of the regionally renowned chocolates from Lake Champlain Chocolates revolves almost entirely around special occasions in the calendar year, for which the fine creations in high-quality packaging be given as gifts. Chocolate bars, on the other hand, are available all year round. The family business is based on the border with Canada, in the US state of Vermont in Williston, near the lake that gives the company its name.

The praline manufactory's products differ in terms of production and packaging: some of them are produced produced and packaged by machine, automated or semi-automated, others are handmade. Accordingly, the product lines are either very complex and labour-intensive, or only a few steps are required. This applies, for example, to the table packaging line from Loesch Packaging Technology (LoeschPack) from Altendorf, which can pack up to 200 bars fully automatically in this configuration.

Solution for the new requirements

With the Further development of its products and systems for more automation the manufacturer of premium chocolates reorganised its packaging technology for chocolate bars. In order to increase the production of chocolate bars, the company Lake Champlain first upgraded its moulding plant. To ensure smooth implementation, however, the company also needed a packaging system that could keep pace with the new production. LoeschPack supplied the right Two-stage fold wrapping machine.

"We got to know the machine manufacturer years ago at the interpack and PackExpo trade fairs. When we were looking for a supplier who could help us switch from an open fold wrap to a sealed full wrap, we learnt that LoeschPack already had the right solution for our idea. The US market for chocolate bars had changed. More and more retailers were now placing the bars vertically in the carton. Our products, which were wrapped in film at the ends, were therefore less protected. We looked at a comparable machine from LoeschPack on the market and were impressed."

Eric LampmanPresident at Lake Champlain

"Our system consists of the LOMATIC feeding and distribution system with integrated belt storage and the LTM-DUO packaging machine. The system takes the sheets from the upstream moulding machine, arranges them and feeds them to the packaging machine. An additional belt accumulator in the LOMATIC can store the products for a short time and then retrieve them again. This balances out production fluctuations and increases the efficiency of the entire system. The LTM-DUO first packs the bars hermetically sealed and then wraps them in paper or cardboard."

Christoph BächmannProject Manager at LoeschPack

It took around nine months from the start of the project to commissioning, during which the two companies worked intensively on the project. Successfully, as John Weishaar, Manufacturing Manager at Lake Champlain, confirms: "With the new moulding plant and the new packaging plant, we were able to triple our original throughput. We have also improved the quality of our packaging. In contrast to the old machine, we can now reliably hermetically seal our sheets at all ends for a longer shelf life with the new system solution."

Producing and packaging chocolate sustainably

In addition to a successful project Lake Champlain and LoeschPack also share their sustainable corporate orientation. With the system solution from Altendorf, the chocolate manufacturer can not only package its bars faster and to a higher quality, but also more sustainably. "The LTM-DUO is easy to operate and requires little service and personnel. It packs many different recipes with little effort, from milk chocolate to chocolate with whole nuts," emphasises Bächmann.

The customer can change the recipe and format easily, quickly and in a user-friendly way. Lake Champlain is flexible in its choice of packaging. The Changing from aluminium foil to OPP film at the first station is just as easy as changing from paper to cardboard in the next step. Once the sheets have come off the conveyor belt, the LTM-DUO, which is easily accessible in all areas, is easy to clean.

In addition to the partnership with LoeschPack, Lake Champlain also attaches great importance to high-quality packaging, products and ingredients: "Over the past twelve years, we have increasingly focussing on natural and green products and simple recipes. To achieve this, we mainly use sustainably produced chocolate and other raw materials and do not use palm oil, among other things. Where possible, we work with local farmers and suppliers. And for our For the most part, we use completely regionally recycled paper and cardboard for our gift packaging", reports Lampman proudly.

When it comes to packaging technology, however, the Americans rely entirely on "Made in Germany".

Shared knowledge and direct communication

Good communication and the expertise of all those involved were also key to the success of the project: "The collaboration with LoeschPack has been great so far because we have not only been able to utilise our own resources, but also the knowledge, experience and perspectives of experts from Germany were able to do," emphasises Lampman. "LoeschPack coordinated the installation of the machine very well," says Weishaar with satisfaction.

"The technicians from Altendorf correctly and professionally assessed the system and its potential right from the commissioning stage. And our machine operators were able to benefit from the skills of the German experts: We quickly realised that the new system would also set a new benchmark and move us forward as a chocolate manufacturer. We are naturally very grateful to the experts from Germany for the valuable dialogue and the successful project. The figures speak for themselves. They are proof of good technology and that our investment has paid off."

Eric Lampman

Contact with Loesch support is just as smooth. The system can remotely so that the team in Germany can carry out remote maintenance at the touch of a button. is possible. Spare parts are delivered within a very short time. Respectful and uncomplicated dialogue is just as important to the partners: "We have valued open communication right from the start. If something doesn't fit, we talk about it and look together at what we can improve or do differently and what new ways we want to try out. Authenticity and being open and honest with each other are important values for us, which we also live by as a family business," reports Lampman.

Bächmann also appreciates this approach: "We maintain a down-to-earth partnership with our customers. The working atmosphere with our colleagues from Vermont is very pleasant, the Employees are committed and proud to have worked for the chocolate manufacturer, some of them for decades. It was a great project in which we, as a packaging system manufacturer, were involved with our Bringing core expertise in chocolate packaging to a medium-sized, up-and-coming company could." He is positive about the future: "We naturally hope that we can continue to support Lake Champlain with our packaging solutions in the future and continue to grow together with them."

More news from the magazine

Translucent paper seal labels for pharmaceutical packaging

Packaging machine manufacturer in flow

Powerful automation for mills

Decentralised signal processing with the Schmersal Safety Fieldbox