With its flexibility and compactness, the new end-of-line universal box gripper from Fipa aims to score points with customers from the packaging industry in particular. It is aimed at users who want to pack constantly changing cardboard boxes in small batch sizes. The pneumatic gripper prepares the cardboard boxes, closes them and then takes over palletising tasks.

The target sectors for the new Pneumatic gripper The specialist for vacuum, gripper and lifting technology from Ismaning sees the pharmaceutical, food and cosmetics industries, among others, as the main target groups. Manufacturers with a large product range, different packaging sizes and little space for large containers are particularly targeted. End-of-line packaging systems. With the new gripper concept, which will be presented in the coming weeks, it will be possible to set up a complete end-of-line packaging station in a space measuring 2 x 2 x 2 metres. It is also possible to connect the gripper to an inexpensive small robot.

The basic model weighs just eight kilograms

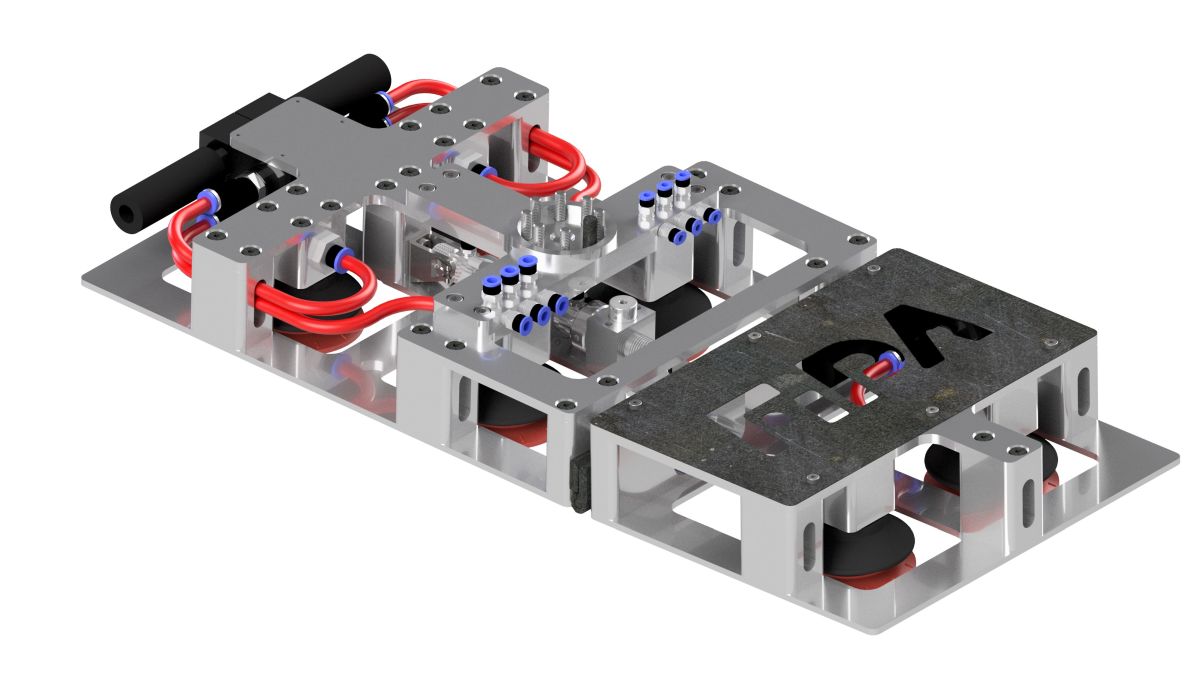

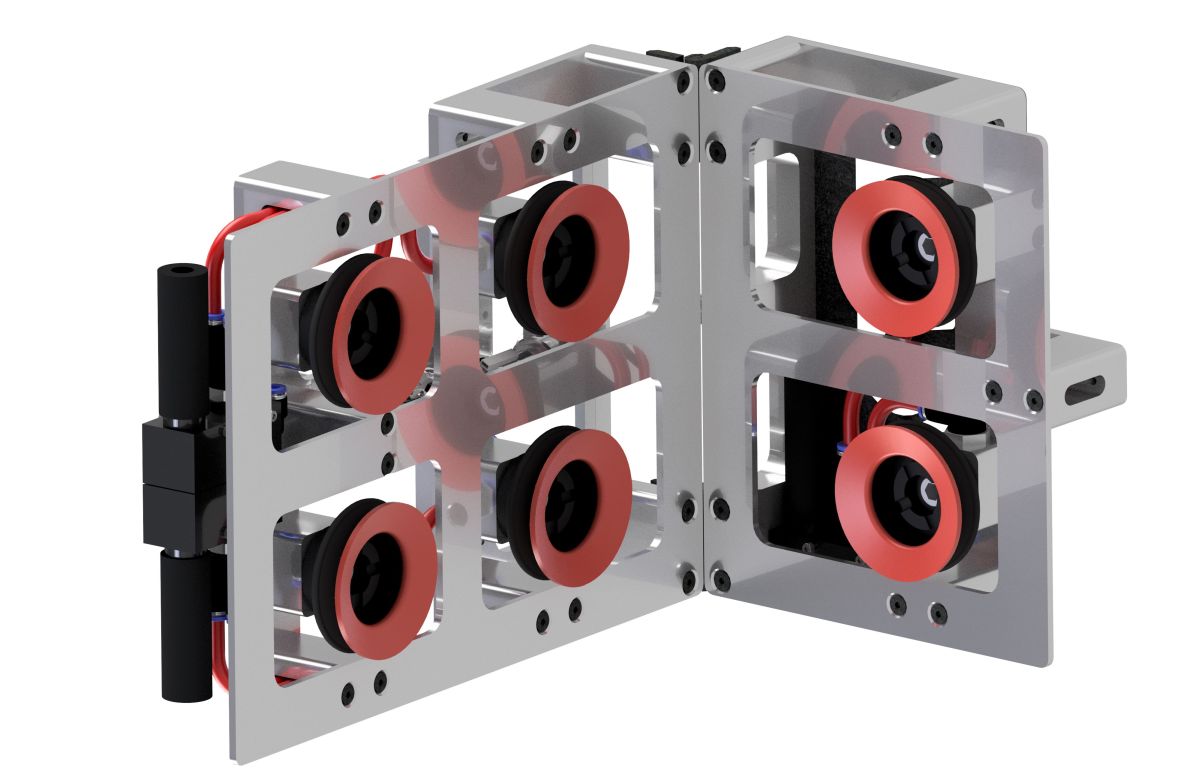

The company's own development department then designed a space-saving, modular system that can be customised to meet individual customer requirements. Gripper system on the basis of a weight-optimised Support structure made of aluminium. This can be connected to robot systems with the corresponding peripherals via the usual interfaces and is then programmed and controlled via the robot controller. The lightweight design means that the basic configuration of the gripper weighs just under eight kilograms. Despite this, loads of up to 50 kilograms can be moved.

According to information from Torsten Eifler, Director of the Packaging business unit at Fipa, the gripper fulfils three functions at once: erecting, closing and palletising. It therefore offers an alternative to the large and complex packaging gantries.

Eifler also emphasises the energy efficiency of the gripper: "Thanks to the use of efficiently operating Multi-chamber ejectors At 160 standard litres per minute at six bar, it consumes only a small amount of compressed air.

Around 100 configuration options

Fipa estimates the number of configuration options for the modular gripper at around 100. It can be extended with components from the existing range for Vacuum and gripper technology can be extended. Configurable features include the robot connection, quick changer and the mask size for adaptation to the final carton dimensions. A powerful Quick coupler for connecting the gripper to robots from other manufacturers reduces set-up times and at the same time increases flexibility in the packaging process.

In addition, the gripper can be equipped with a control unit for the Blow-off pulses to optimise the cycle times can be equipped. With optional light sensor, vacuum switch and clamping cartridge, further adaptations and optimisations of the processes are possible.

[infotext icon]You can find more information about Fipa products on the Company homepage.

[/infotext]