Customers of Siemer Verpackung value their packaging manufacturer for its customised advice and flexibility. With the commissioning of the new, modular Visionfold 80 with handypack packaging system from Bobst, the company has once again improved its responsiveness in folding carton gluing.

Delivery times of just a few days used to be unthinkable in folding carton production. Thanks to the ease of operation and the high degree of automation of the latest production technology things are different today. At least with the Siemer Packaging GmbH in Ronnenberg near Hanover:

„We are currently processing an order for which our customer was only able to decide on the material at a late stage. We have a total of five days to produce his folding boxes. However, we have also delivered orders within three days.“

Laura Grondey, who runs the company together with her sister Maren

Of course, this is only done when there is actually a fire at the customer's premises. „We owe this responsiveness to two factors in particular: the special commitment of our team and the efficiency of our production process,“ says Maren Grondey. The investment in the Visionfold 80 folder gluer from Bobst fits seamlessly into this scenario. With it, Siemer Verpackung now has a total of four machines from the Swiss manufacturer for further processing: an SP 102 E and a Novacut 106 E for flatbed die-cutting. In addition to the new machine, an Expertfold 110 is also available for folding carton gluing.

Further processing optimised

Siemer Verpackung GmbH was founded in 1906 as Kartonagenfabrik Ernst Siemer in Hanover. Today, the fourth-generation family business, run by sisters Laura and Maren Grongey and based in Ronnenberg, supplies customers throughout Germany and Switzerland, who in turn distribute their packaging to many parts of Europe. The Visionfold 80 has replaced an older machine at Siemer that was getting on in years. Most recently, the Expertfold 110 was used for all orders that had to be checked for sub-mixing.

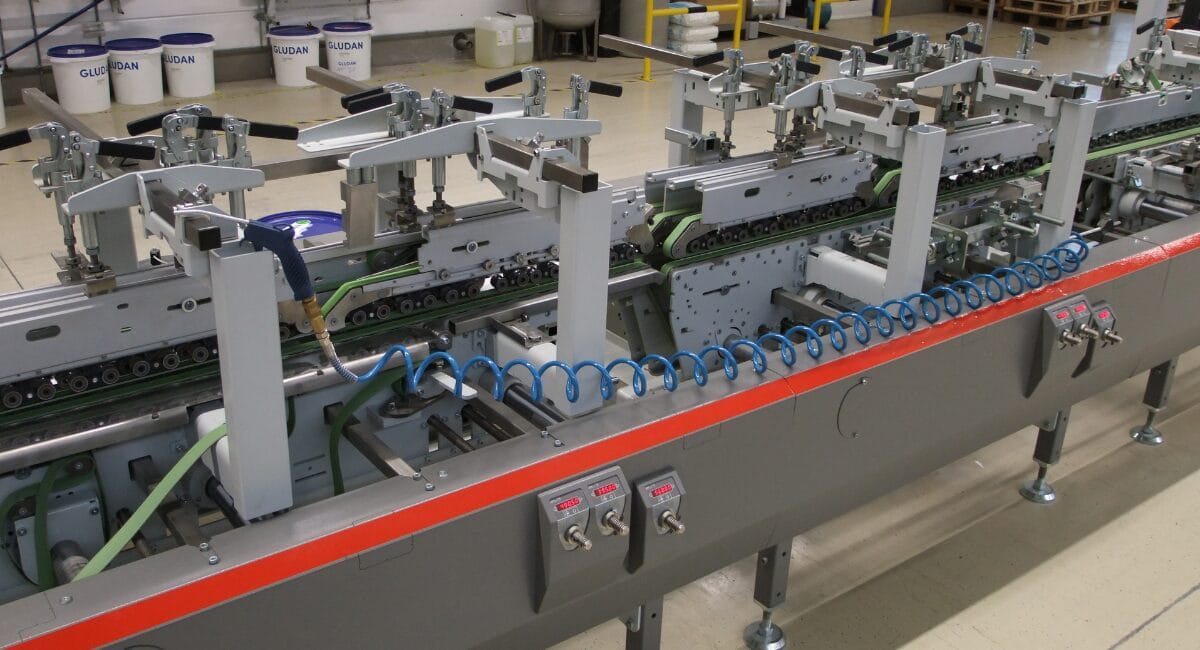

With just over 30 employees, the company produces a large number of Folding cartons for food supplements and pharmaceutical products, among othersproducts for which sub-mix control is essential. As a result, a large part of the Expertfold 110„s capacity was taken up with these orders. For this reason alone, a new machine was needed. “We wanted to maintain our flexibility in production," says Maren Grondey, looking back. The Visionfold 80 with handypack packaging system, which was recently commissioned and enables a particularly simple removal process for manual packaging in the optimum orientation, has enabled the company to expand even further.

„In folding carton production, complicated gluing is increasingly in demand. For example, multi-chamber boxes and inner gluing. That's why we needed a modular machine that we could configure flexibly to realise the most complex bondings.“ Laura Grondey

Conventional folder gluers have to fold inner chambers in a confined space. If the flaps of the blanks are folded too quickly, this can impair the quality of the packaging. For this reason, folding carton manufacturers who only have standard machines run them more slowly for orders with customised gluing. They can therefore Do not fully utilise the productivity of their systems.

Additional modules expand the range

Siemer Verpackung has chosen a different path and has equipped its Visionfold 80 with an additional folding bottom module, 1.5 metre long module for additional folds can be configured. „The machine produces the packaging reliably and in perfect quality, even at high running speeds,“ emphasises Laura Grondey: "The company works with a range of different folding and pre-breaking devices in the Visionfold 80. They can be positioned quickly and easily in the machine's additional module.

„Pre-scoring is more important than ever for our customers. It benefits them in their filling processes because the folding cartons are reliably erected here and therefore run smoothly through the machines.“

Maren Grondey

Significantly higher productivity

With the new machine, Siemer Verpackung has become significantly faster in folding carton production, both in terms of set-up and production. Compared to the old machine, the Visionfold 80 is characterised by at least 30 per cent higher mileage out. At its peak, it reaches speeds of up to 350 metres per minute. Even more important is the fact that it can produce more complex packaging in a single machine cycle. Laura Grondey cites automatic bottom boxes with additional flaps at the top as an example. „We used to have to send such orders through the machine twice.“

Set-up times are also reduced, especially for more complex folding cartons. With Up to 15 production changes in one shift this is also an important aspect. No manual settings are required for the Accueject ejection system, for example. On the Accufeed feeder, the right/left cutting alignment module supports fast set-up.

Thanks to its compact design, the machine is easy to operate. Smaller folding boxes in particular are easier to produce with it. The Intuitive operation via the touchscreen display of the Sphere HMI interface is easier than ever before. „I don't know what could be done better with this machine,“ says one of the company's machine operators. The fact that they enjoy working with the new technology is also particularly important in times of a shortage of skilled labour.

Effective division of labour

With the commissioning of this folder gluer, the company has also optimised its work process in further processing in other respects: since then, it has increasingly been using its Expertfold 110 for automatic bottom boxes, while the new machine produces the majority of length-seam boxes and packaging with special gluing. Thanks to this division of labour, the Changeover effort minimised during production changes.

Siemer Verpackung will have additional options for optimising its further processing in the future with the cloud-based digitalisation platform Bobst Connect can tap into. It provides powerful functions for monitoring the most important machine data as well as efficient control and optimisation of production in real time.

Siemer Packaging offers No minimum order sizes. Depending on its customers' requirements, the company produces packaging in quantities of less than 100 units. In other words, orders that other packaging manufacturers would turn down. The largest runs are produced for customers whose products can be found in drugstore chains.

„Around 60 to 70 per cent of the packaging we produce is for organic products, a large proportion of which is for cosmetics. Typically, our customers are open to our personalised advice. They come to us with their ideas. But we often end up producing their packaging in a completely different way. For example, by reducing the colours to what is necessary.“

Maren Gronday

Focus on cost optimisation

One example of cost optimisation is so-called combination prints. These are produced for customers with very extensive product ranges that include hundreds of Pack sizes in different print runs need. These orders can easily total half a million or even more folding cartons. „We enjoy working out the perfect production method at the most favourable cost in each case. Our customers trust us to do this in their interests,“ says the expert.

The topic of sustainability has always been of central importance at Siemer Verpackung. The company therefore welcomes the high energy efficiency of the new technology. And as the packaging is produced reliably, waste is also reduced. And while there is much talk of corporate social responsibility (CSR) in other companies, here, too, things are done with heads down: more than 30 per cent of employees have health impairments and are fully integrated into operational processes.