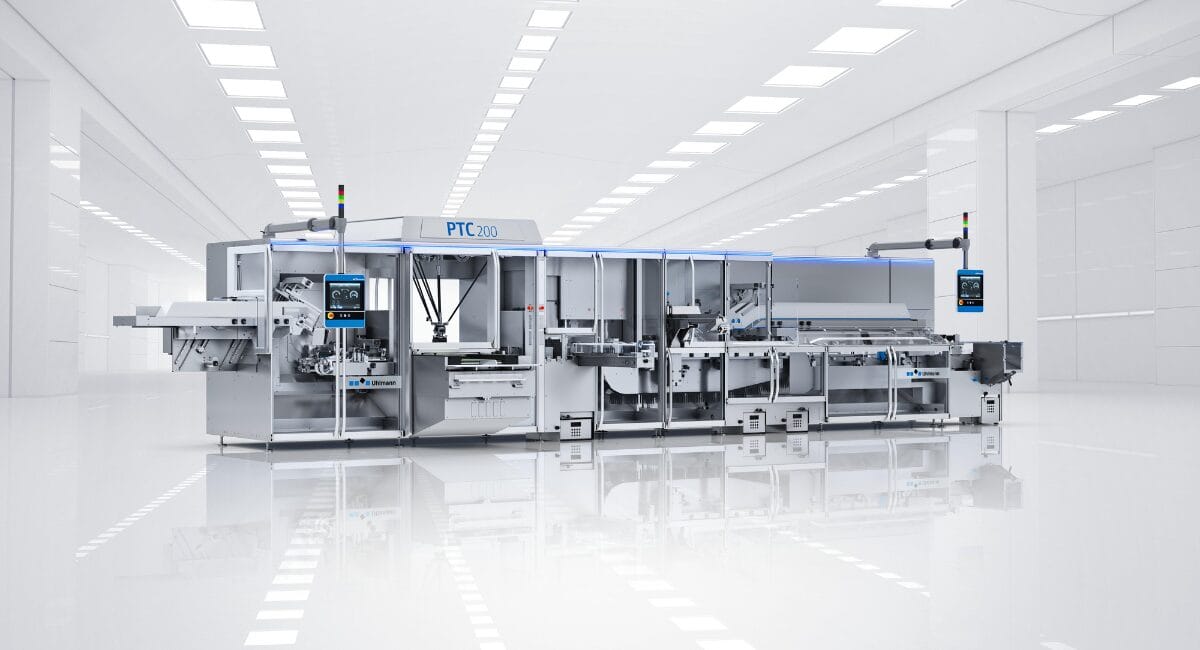

Pharmaceutical companies want to use fewer resources when packaging parenterals, reduce emissions, offer safety and pack flexibly and efficiently. At the same time, packaging is becoming increasingly complex and versatile. Uhlmann Pac-Systeme offers a solution for these diverse requirements with its PTC 200 Parenteral Tray Centre cartoning line. The line packs ampoules, vials, syringes and pens sustainably.

„The aim of product development at Uhlmann is to make our packaging solutions highly flexible so that our customers can process different parenteral product shapes and sizes as well as different packaging materials and shapes reliably and efficiently. The Parenteral Tray Center PTC 200 makes this easy to implement - with a high degree of automation and digitalisation.“

Werner Blersch, Strategic Product Manager Parenteral Packaging at Uhlmann Pac-Systeme

Thanks to the modular machine concept, the PTC 200 is able to produce a wide range of product configurations with high efficiency. With up to six feeders, syringes, ampoules, vials and associated accessories such as adapters or leaflets are packed quickly and reliably. With optimum settings up to 200 trays or folding boxes per minute possible. An efficient stacking unit allows several trays to be stacked on top of each other and then inserted into a folding box. This makes the PTC 200 space-saving and efficient.

Parenterals are usually secondary packed in sealed blister packs or unsealed plastic trays and then inserted into folding cartons together with the package leaflet. However, the growing importance of parenterals and the desire for greater sustainability require alternative packaging solutions that are not just safe and efficient, but also in terms of CO2-Balance sheet and resource consumption convince. Packaging made from mono-materials such as cardboard is not only environmentally friendly, but also versatile. With the PTC 200 Uhlmann now offers a flexible solution that can pack in both cardboard trays and conventional plastic clip blisters. The ability to process a wide range of product formats and pack sizes means that pharmaceutical companies can adapt their production to the requirements of the market with complete flexibility. In addition, the intelligently designed changeover process allows particularly Fast batch changes.

Seamless monitoring and gentle product handling are essential, especially for parenterals. The PTC 200 is controlled via a human-machine interface that utilises the SmartControl operating system. The PTC 200 can also be managed via the modules of the Pexcite software solution. Pexcite offers a special Track & Trace module, which can be used to track and trace products in the interests of patient safety. Track every single product individually and seamlessly via a UDI code from production to the pallet. The UDI code also ensures that a faulty product is recognised. This means that instead of the entire packaging unit, only individual products are disposed of and waste is reduced. Furthermore, gentle product handling across all machines enables high machine availability and low downtimes.

Source: Uhlmann Pac-Systems

Uhlmann Pac-Systeme at the Achema: Hall 3, Stand F25