Flexibility is playing an increasingly important role for companies in a dynamic world. Baumer hhs now supports the application of adhesives and quality control for corrugated cardboard packaging with the CorrBox Solution.

„Legal requirements for the sustainability of packaging, zero-defect production, increasing cost pressure, a growing shortage of skilled labour and instability in global supply chains - a whole series of current challenges have prompted us to rethink adhesive application and its monitoring in the production of corrugated cardboard packaging. In doing so, we have set ourselves goals that initially seemed incompatible. The result is the revolutionary CorrBox Solution system for Flexo-Folder-Gluer (FFG). It is characterised by unprecedented performance and flexibility - and thus offers our customers significant advantages.“

Andreas Schneiders, Business Development Manager Corrugated at Baumer hhs

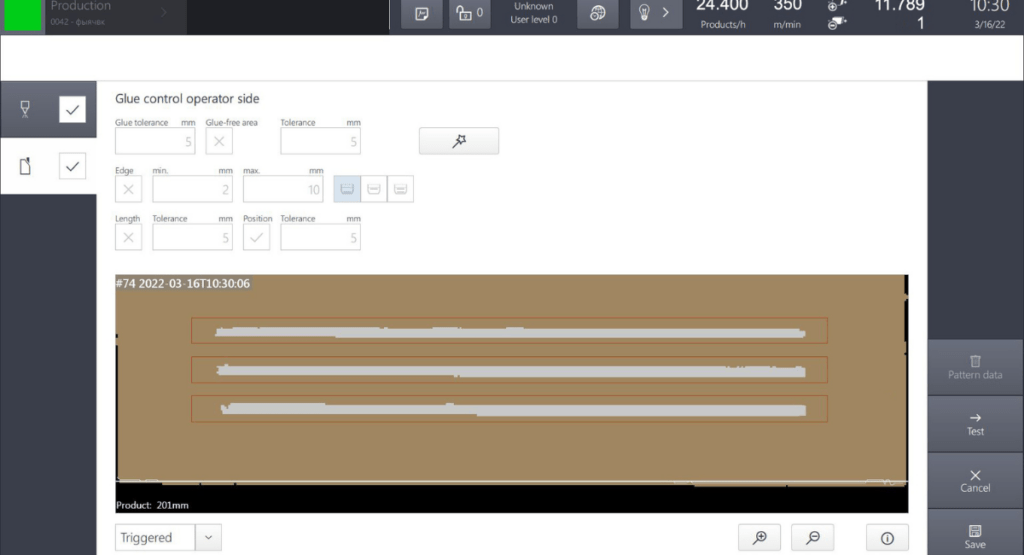

For the CorrBox Solution, for example, the company has developed the PGD 1000 Sensor with camera-like properties developed. The PGD 1000 offers corrugated cardboard processors the freedom to bond all types of packaging - without having to worry about monitoring and the condition of the material surfaces. And it saves them having to decide whether to apply their adhesive with sensors or cameras. monitor.

„Flexibility in the adhesives that can be used was one of our most important goals when developing the CorrBox Solution. In view of the dramatic situation in global supply chains, our customers benefit from this all the more today,“ says Thomas Walther, Head of Business Development at Baumer hhs. The fact that adhesives can be dispensed with fluorescent additives, This has another advantage: manufacturers of corrugated board packaging can use a wider range of different adhesives.

The CorrBox Solution also has a multiple application head. It is based on the innovative technology of the PX 1000 cold glue valve, which is more tolerant of viscosity fluctuations. This is thanks to a electromagnetic drive with a clamping force that is 42 per cent higher than that of the predecessor model PL-500. The new multiple application head guarantees the best adhesive application results even at the limits of viscosity, without the need for complex parameter settings.

„The first customers tell us that the multiple application head has doubled their trouble-free production time between two cleaning intervals. In other words, the cleaning effort has been halved. The risk of incorrect gluing has been reduced to the same extent. In addition, adhesive consumption has been reduced by up to 60 per cent.“

Thomas Walther

These savings are made possible by an optimised stitching algorithm that works hand in hand with the speed of the PX 1000 application head. Thanks to this technology, previously continuous adhesive lines can be divided into a sequence of short lines without any tailing. The result is Adhesive savings with often even increased adhesive strength. This also benefits the sustainability of the packaging.

The CorrBox Solution is modular design, which offers the choice between different product guides and between a variety of different control, monitoring and optional software functions.

Source: Baumer hhs

More news on adhesives

CCL Industries expands labelling expertise

Amcor is looking for innovations

Jowat strengthens the circular economy with sustainable packaging adhesives

Robatech starts co-operation with ABB