One solution for many labelling tasks is the Legi-Air 4050 B series of label printing and dispensing systems from Bluhm Systeme, which works extremely reliably even in harsh environments. Thanks to the use of print modules from leading manufacturers and the consistent modular design, it is very flexible and can be easily integrated into existing processes.

The Legi-Air 4050 B is available in four versions. Various applicators are available. For the labelling of Products with varying heights a sensor is available that detects the distance to the labelling product.

Guaranteed reliable readability of barcodes

Depending on the print module, labels with Data in 200 to 600 dpi resolution printed and applied to the product. Depending on the applicator and label size, the system can be used to print up to 240 labels per minute printed and donated. The maximum label length is 210 mm.

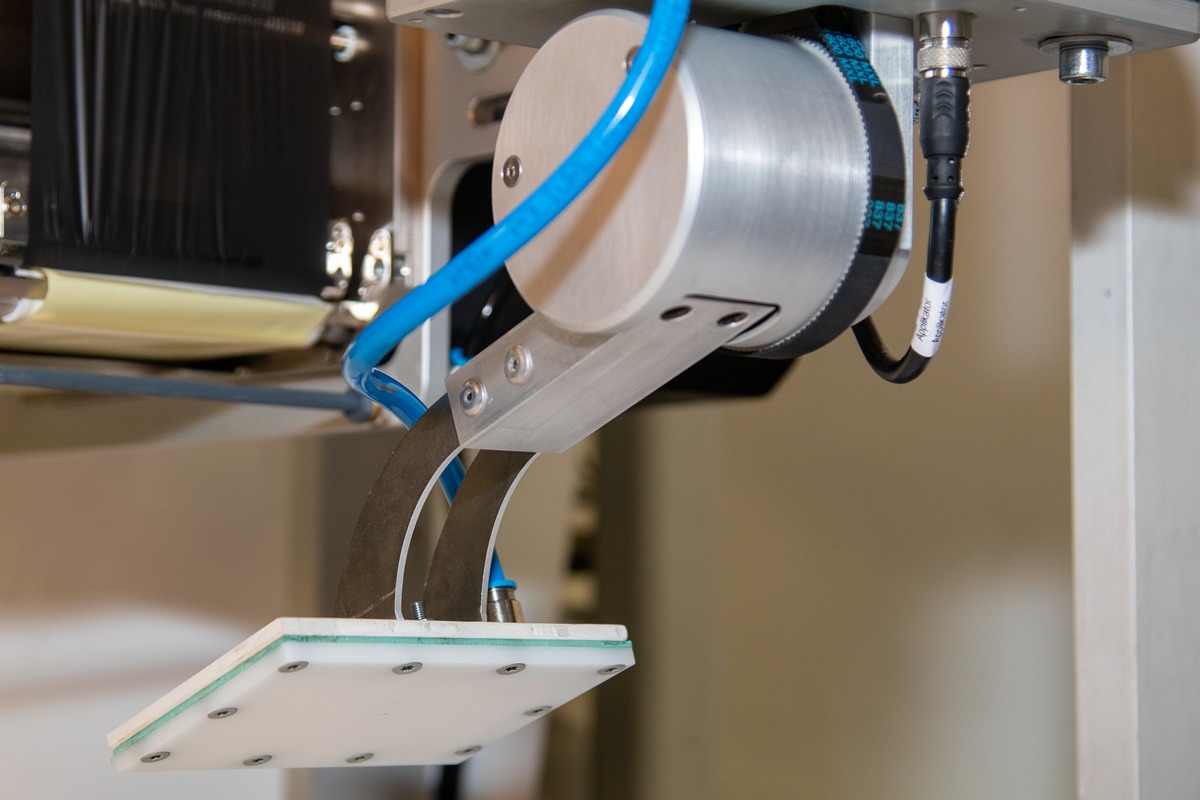

The labels are applied to products, packaging or trays, for example. Contactless using the tamp-blow or wipe-on method. The label is applied to the stopped or moving product. All labelling positions and installation positions are possible, which means that a Wide range of customised solutions realised with this standard device.

A Display controller with a large, multilingual text display enables a Simple operation. Labelling reliability is guaranteed by the label-on-tamp sensor. It checks whether there is actually a label on the pad plate. System and maintenance information ensure quick and easy diagnostics.

Everything in view

If required, the dispensing systems can be controlled by the Legitronic Labelling Software or the Nicelabel Software take place. The Networking is possible via the Bluhmware possible. This increases throughput times and production reliability.

Targeted Operator information on the machine status are displayed in plain text. Storage options for label and product-specific parameters can be called up quickly and repeatedly.

Source: Bluhm Systeme