The trend in the food industry is towards more variations in packaging sizes. With the help of robot-supported systems for repackaging and palletising from ABB, an American pretzel stick manufacturer was able to achieve fast product changeovers and high productivity.

Although the „Dot's Homestyle Pretzels‘ brand was only founded in 2012, it is already the third largest manufacturer in the USA in terms of turnover. In addition to the existing production facilities in North Dakota, Arizona and Kansas, the company recently opened a fourth factory, also in Kansas, to meet the growing demand for its products. The site is characterised by a Consistently automated product preparation, handling and packaging out. Like the other Dot's plants, this facility also operates according to a 24/7 production schedule.

An investment in flexibility

When building the new plant, Dot's invested in forward-looking automation. For this, a system had to be found that can handle a whole range of different packaging sizes. Dot's twisted pretzel sticks are available in three flavours and in eight different packaging sizes. The most popular retail size of around 450 grams is also available in two different boxes: in standard boxes, in which the packs are laid flat as well as special display boxes for the point of sale, in which the packs stand upright.

To achieve the necessary flexibility, Dot's turned to automation specialist Viking Masek Robotics & Automation (VMRA).

„The biggest challenge for VMRA was to develop packaging systems that cover all the different packaging sizes and can be configured for both upright and horizontal bags. Basically, we had to use robotics and automation to pack all the products that we had previously handled manually.“

Kent Schmidtberger, Project Manager at Dot's Edgerton location

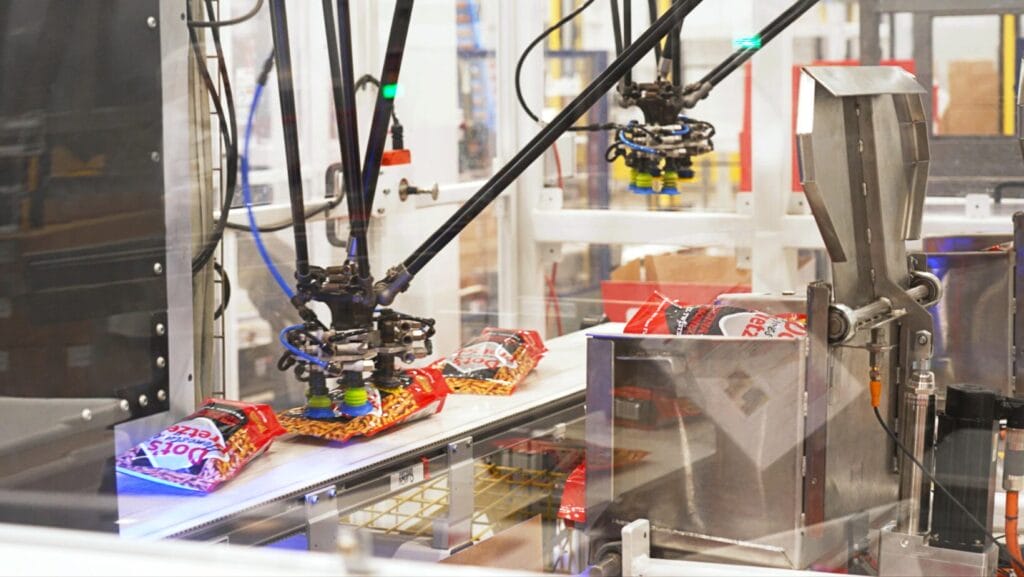

VMRA designed two parallel packaging lines, one with three ABB delta robots of the type IRB 360 FlexPicker for the smaller bags and one with two FlexPickers for the larger ones. The Delta robots from ABB can handle payloads of up to six kilograms. They take the packaging from a conveyor belt and place it in the different sized boxes using different vacuum grippers.

The three smaller bag sizes are vertically filled tubular bags with heat seals at each end. The packaging line for these bags is optimised for maximum throughput, with automated changeover to meet the different requirements for each size. Changing from one bag size to another only takes a few minutes and is started by pressing a few buttons on the operating display. The machine automatically adjusts various parameters to process the next bag size.

The 450 gram bags are picked up by the robots and placed flat in a tipping container next to the box. As soon as the container is filled with the appropriate quantity, it automatically tilts and places the bags upright in the box. As a result, they are in the display boxes already correctly positioned for presentation at the point of sale. The bags destined for distribution centres are packed flat in the standard boxes.

The line for the large bags also includes a mould changer that switches between two different grippers - each adapted to the corresponding product size. VMRA worked closely with the Dot's production team, to optimise the vacuum grippers. Their geometry, suction cup design and robot programming are designed to maximise performance and service life.

One palletising robot for both lines

The packaging lines lead to a single palletising robot from ABB, the IRB 660. With a The robot can reach the cartons on both conveyor belts within a range of 3.15 metres. By alternately picking up cartons from each conveyor belt, it can build separate pallets for each product size in parallel. The palletising robot utilises a vacuum-assisted foam surface gripper designed by VMRA. This means it can also pick up several cartons to ensure optimum throughput. Finished pallets are transferred to an exit conveyor belt before being wrapped in stretch film for dispatch and sent to the warehouse.

System designed with ABB RobotStudio

VMRA used RobotStudio, ABB's offline simulation and programming software to design the robot lines. With two application-specific RobotStudio add-ins, PickMaster for the packaging lines and the Palletising PowerPac for the palletising system, VMRA tested realistic simulations of different configurations, to achieve the optimum design for each line.

Source: ABB