At Automatica in Munich, Weiss will be focussing on linear workpiece transport. With the linear transfer systems from the automation specialist, a large number of process stations can be accommodated in a very small space. At the same time, the linear transfer systems serve as functional subsystems in combination with the other automation components.

Weiss has four linear transfer systems in its portfolio. Thanks to the different drive types, which are either used in a fixed cycle by a cam drive or freely programmable thanks to a linear motor, a wide range of requirements are covered. Weiss supplies the linear transport solutions pre-configured, pre-parameterised and pre-commissioned. This saves users and integrators valuable time. The repeat accuracy is between 0.02 and 0.06 mm in the x, y and z directions. Depending on the system, workpieces weighing up to 50 kg can be moved. The wide range of applications and the combination options with pick and place modules, linear axes or rotary indexing tables make the LS series an interesting subsystem for projects with short project times.

The potential of digitalisation

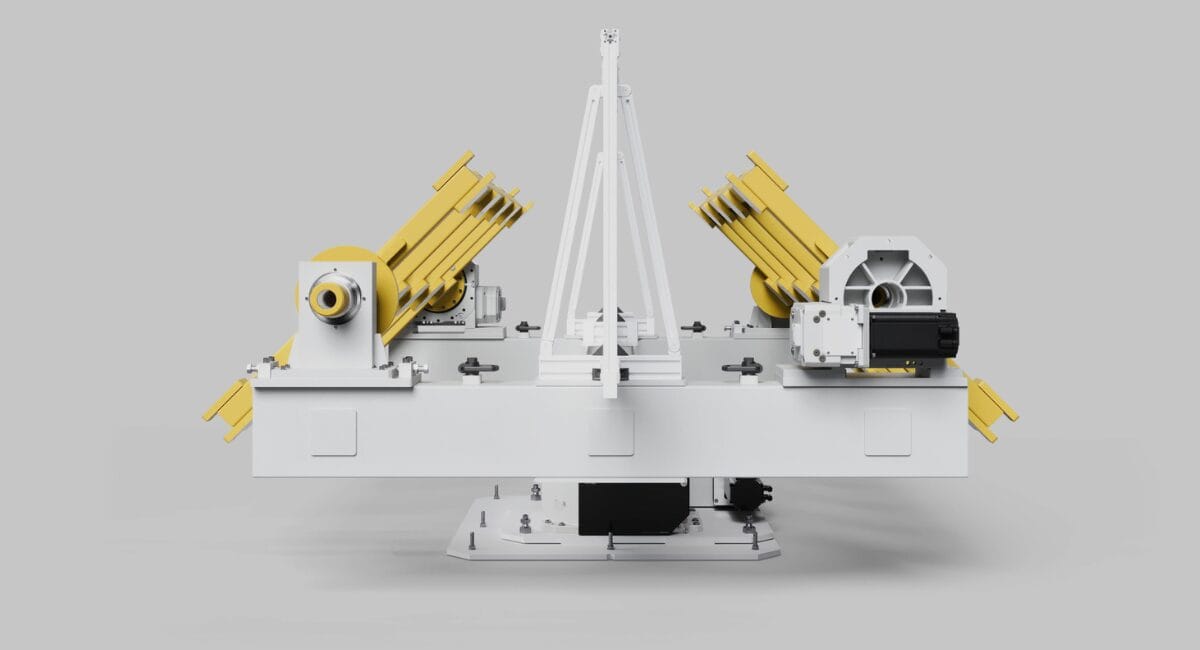

In addition to subsystems for linear workpiece transport, positioning solutions for robot applications complement the portfolio on show in Munich. The Trunnion and H-turners reliably position heavy and large workpieces in applications such as robot welding. The Trunnion and H-turners add additional axes to industrial robots and thus enable efficient production. The Weiss positioners are based on the proven rotary indexing tables of the CR series.

Here Weiss has recently the fifth generation whose portfolio is being further expanded. The rotary indexing tables are characterised by improved performance. According to the manufacturer, they move heavier workpiece weights compared to previous tables of the same size. Weiss is also tapping into the potential of digitalisation with the fifth generation of rotary indexing tables. Users can read the current status of the automation component via a smart board. The Smart Board is the future interface for comprehensive production digitalisation.

Weiss at Automatica 2025: Hall A5, Stand 306

Source: Weiss GmbH