The Fraunhofer Institute for Process Engineering and Packaging IVV is focussing on the current challenges facing the food industry and will be presenting appropriate solutions at IFFA. They will be addressing various difficulties that companies are facing.

The holistic concepts respond to the diverse requirements, that Industry 4.0, climate protection and the shortage of skilled labour pose for companies: From the utilisation of raw materials to individual solutions for safe, automated processes, including hygienic design consulting and the development of sustainable packaging made from recyclable packaging materials.

For manual cleaning processes, the intelligent, sensor-monitored cleaning lance „CleanAssist“, which enables consistent reproducibility and quality assurance for the first time. In the area of food safety, a customisable „Co-Control“ sensor is being developed for the first time. Detection of organic soiling for particularly hygiene-critical environments. With regard to meat alternatives, the Fraunhofer IVVhow Customised food ingredients and market-ready products from plant-based protein sources are created.

Virtual cleaning assistant "CleanAssist"

Researchers at the Fraunhofer IVV have developed the first intelligent cleaning lance in a ZIM-funded joint project to ensure a safe and reproducible cleaning process for the first time, even when cleaning is carried out manually. The lance integrated sensors enable the cleaning process to be logged. All relevant process parameters, the cleaned areas and their cleaning quality are automatically recorded.

The subsequent transmission of the data to an AR device (glasses, tablet or smartphone) projects a „digital twin“ into the real cleaning environment in real time. In addition to consistent quality assurance and documentation of cleaning, the „CleanAssist“ also enables a guided cleaning process. Optimisation of cleaning processes and helps to avoid errors that reduce product quality due to incorrect cleaning.

Optical detection methods

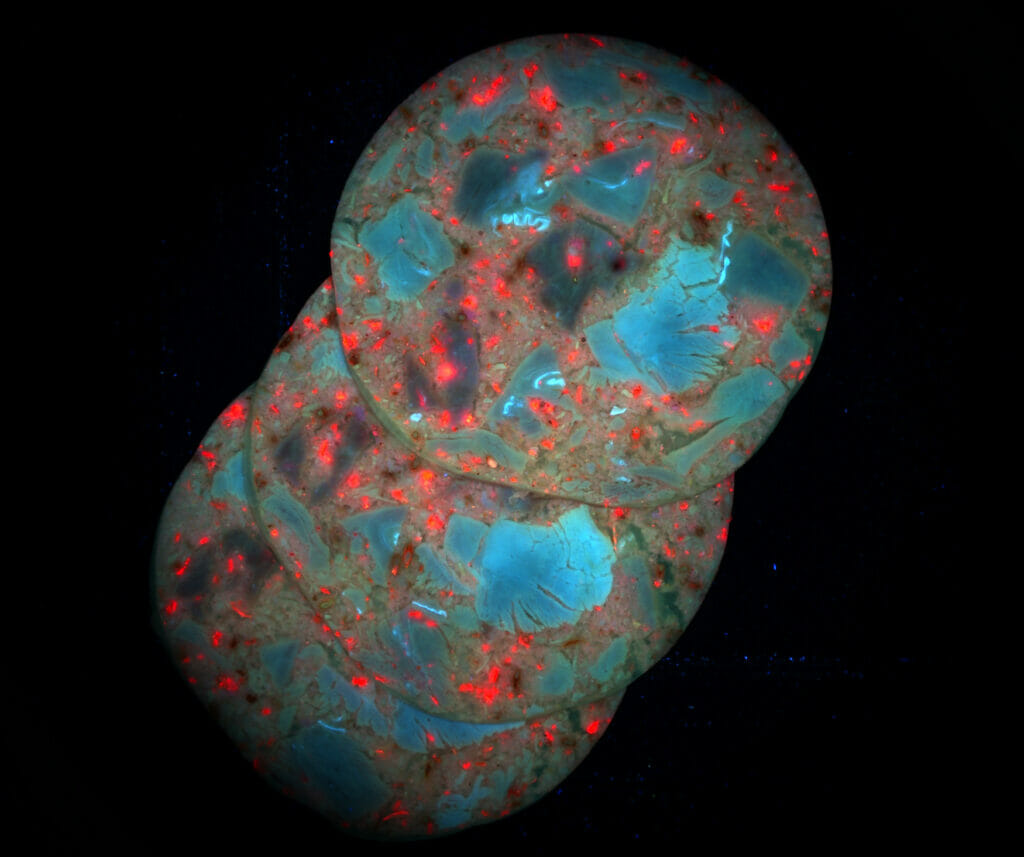

The optical detection system „Co-Control“ was developed at the Fraunhofer IVV based on extensive expertise in the field of sensor technologies and the application-orientated design of camera-based measurement technology. The system is based on the Fluorescence analysis using UV radiation and enables the spatially resolved detection of organic contaminants on 2- and 3-dimensional components. It can be used both as a mobile photo chamber and as a customised inline system. Contamination can be quantified directly in production or as an atline or offline solution, thus eliminating the causes of quality problems.

Proteins as a meat alternative

The continuing The trend towards giving up meat has increased the demand for high-quality alternative proteins let. Based on its experience in the production of protein ingredients and the characterisation of their technological properties, the Fraunhofer IVV is working to continuously improve the sensory quality of meat alternatives. After all, very few consumers want to give up familiar dietary patterns. The Fraunhofer IVV is responding to this high demand for meat alternatives with the Fesearch into valuable sources of protein from plant-based raw materials and insects fair.

From 14 to 19 May 2022, Fraunhofer IVV will be presenting its solutions at the IFFA in Hall 11.1 Stand B70.

Source: Fraunhofer IVV

Fraunhofer IVV - More news

Artificial intelligence as a game changer in plastics recycling

Bio-based film for MAP packaging

AI application hub presents milestones

AI-based assistance system for a more sustainable paper cycle management