As part of the automation of its intralogistics processes, the biotechnology company CSL Behring now relies on fully automated palletising solutions from Asys Life Science.

CSL Behring's Swiss site has set itself the goal of automating manual and repetitive tasks. In this way, the error rate is to be reduced and the yield increased while complying with health and safety guidelines. The focus of the solution is on Automation of intralogistics processes. In order to automate the previously manual processes, Asys worked with the team led by Sven Schwerdtfeger from CSL Behring to develop the right solution.

„This not only included the system itself, but also the development of the product carriers in terms of design-to-manufacturing (DTM). These are easy to automate and offer effective protection against glass-to-glass contact for longer transport distances.“ Oliver Bleher, Director Life Science at the Asys Group

Automated loading and unloading

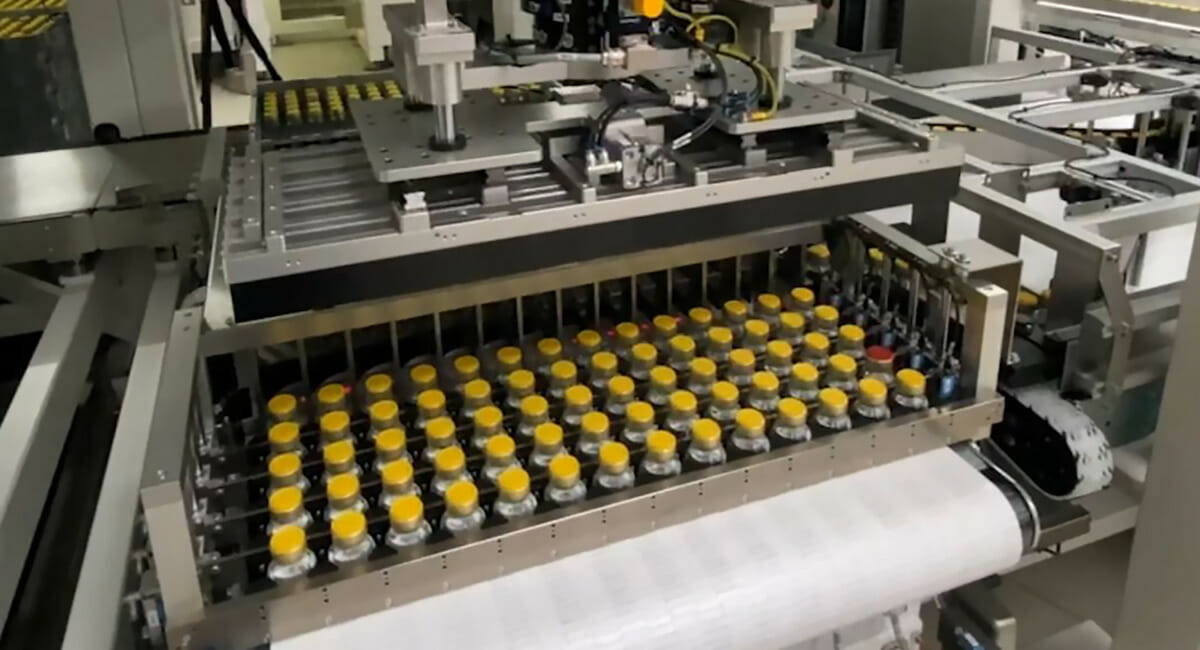

System solutions from Asys Tecton are used for the fully automated loading and unloading of vials on the inspection and packaging lines. These are used prior to the visual inspection of an important human plasma product from CSL Behring, in order to ensure that the vials are filled and then pasteurised, analyse the transparent liquid for particles. For this purpose, the vials must be separated and then reassembled into containers (KLTs). The speed is 200 vials/min. for 50 and 100 ml vial sizes.

All line components are connected to the customer's MES system (Manufacturing Execution System) via an interface implemented by ASYS. The integration of a gantry axis system (x/y/z axes and lift system) is possible. More compact than a robot solution, This made a very space-saving solution possible.

„Thanks to automatic loading and unloading and the direct linking of the transport of empty containers, it was possible to relieve employees compared to the manual process, who can now fulfil important tasks elsewhere.“ Sven Schwerdtfeger, Director of Engineering at CSL Behring.

The error rate was also reduced. The validation experts from Asys Life Science also provided the appropriate qualification documentation to ensure that all systems were GxP-compliant (good practice).

Further work step automated

Another work step was automated on the same machine base: The depalletising for separating the 50 and 100 ml vials and subsequent connection to a cartoning machine with a capacity of 220 vials/min. „The automated unloading from KLT (small load carrier) boxes with a total weight of approx. 30 kg relieves employees massively in their daily work“, says Schwerdtfeger. There is space for two Euro pallets (1200 x 800 mm) at the infeed and outfeed, which corresponds to an autonomy of up to 1600 vials per pallet. The machines are also designed in a GMP version.

[infotext icon]The Asys Group is a globally active technology company and leading supplier of standard and customised systems for the electronics, energy and life science sectors. Asys Automatisierungssysteme GmbH, is the management company of the group. With over 1300 employees worldwide, the Asys Group develops, manufactures and markets high-quality and innovative automation solutions. It has a global sales network with local contacts in more than 40 countries. 20 subsidiaries in Europe, Asia and America enable customer-oriented support[/infotext].SourceAsys : Asys