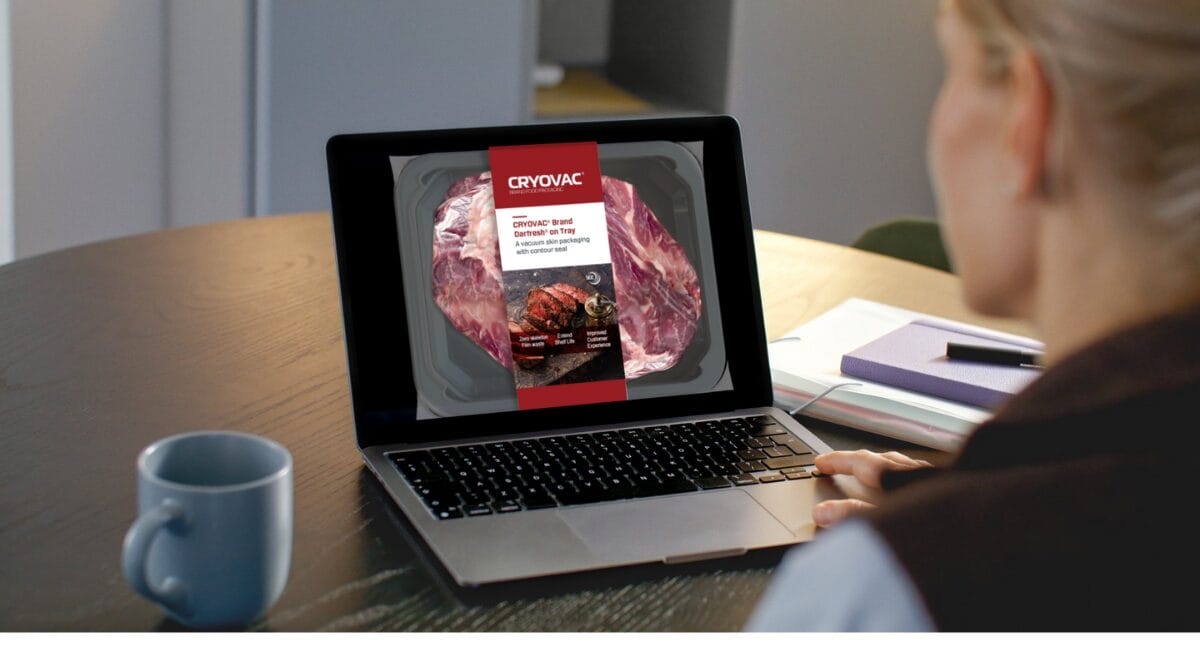

With Darfresh on Tray and Darfresh Rollstock, Sealed Air offers two innovative vacuum skin solutions which, according to the manufacturer, reduce plastic consumption, improve product protection and set new standards for freshness.

With its Darfresh solutions, Sealed Air is launching two advanced vacuum skin packaging systems that meet the requirements of both retail and e-commerce. The Darfresh on Tray and Darfresh Rollstock variants aim to provide resource-efficient, safe and attractive packaging for fresh food products - especially meat, poultry, cheese and ready meals.

The technology combines reduced material usage with longer shelf life and high product safety. The packaging encloses the goods like a second skin and at the same time ensures a high-quality shelf presentation, according to the company.

Darfresh on Tray: waste-free packaging for retailers

The Darfresh on Tray system, which is based on prefabricated trays, was developed in cooperation with G. Mondini. It is compatible with various tray types - including mono-PP, mono-PET and cardboard trays - and enables virtually waste-free processing. Compared to conventional skin pack systems, 30-40 per cent material waste can be avoided, according to the company.

In addition to improved product shelf life, the solution also offers operational advantages: lower material consumption, simplified handling, high-quality appearance with vertical presentation on the shelf and a user-friendly opening system.

Darfresh Rollstock: Thinner films for maximum efficiency

The Darfresh rollstock system is based on thermoformable vacuum skin technology, which was developed in collaboration with Ulma Packaging. The flexible solution utilises specially developed top and bottom films to ensure gentle, contour-accurate sealing.

Plastic consumption can be reduced by up to 25 per cent compared to standard market packaging. At the same time, the shelf life of fresh proteins is doubled compared to MAP systems, which not only reduces food losses but also increases logistical flexibility. The sealing surfaces are tight and leak-proof - an important criterion for retail and transport.

Automation and machine integration

The Darfresh films are designed for automated packaging lines. The rollstock solutions can be operated on Ulma machines with R-Scrap technology. The tray system can be combined with G. Mondini Trave models in various sizes as well as with the „Platformer“ system, which enables high flexibility in production planning.

IFFA 2025: Hall 12.1, Stand E21

Source: Sealed Air