Gallus, a subsidiary of Heidelberger Druckmaschinen AG, develops, produces and sells conventional and digital narrow-web web presses specialising in label and packaging printing. The company has now opened a new innovation centre in St. Gallen, Switzerland.

The Gallus Group is celebrating its 100th anniversary with the opening of a new innovation centre in St. Gallen, Switzerland - the Gallus Experience Center, which will be located in the heart of the city. as a central point of contact for customers, industry experts, stakeholders and the general public and will continue to drive the digital transformation in the market. Three new product launches will also accompany the company's anniversary: the Heidelberg Customer Portal, the new fully digital Gallus One label press with converting and a digital upgrade of the successful Gallus ECS 340.

The new Gallus Experience Centre will be part of the «Gallus Experience Days» customers, partners and brand manufacturers. The centre is dedicated to the „digital transformation“ of the label and narrow web industry and aims to support the Support the future success of the industry by promoting co-operation, to drive innovation and sustainability.

Manufacturers, suppliers, processors, printers and brand manufacturers are invited to use the new facility, test and develop new technologies and learn more about the technological ecosystem. Gallus will also use the facility to showcase its own conventional, hybrid and digital products, software and cloud-based solutions, next-generation machines and technologies from suppliers.

„With labels and packaging now accounting for 50 per cent of the Heidelberg Group's total sales, the new digital and automated solutions that Gallus is unveiling today will play an important role in the future of Heidelberg. This makes Gallus a key pillar in the company's growth strategy, and we are more committed than ever to its long-term future.“

Dr Ludwin Monz, CEO of HEIDELBERG.

With annual growth of over two per cent in global print volumes packaging printing is one of the fastest-growing sectors in the printing industry. Together with label printing, this is an important core area for Heidelberg. As part of its „dual-track strategy“, the company is also focussing on further growth in digital printing. This technology is used in label production, for example, which is one of the areas with the greatest growth potential in the printing industry. A third of all labels worldwide are already printed digitally. Digital printing is thus driving change in this promising market segment, with inkjet printing growing at an annual rate of around six per cent. Heidelberg intends to further expand its market share in this area with the Gallus One.

„We endeavour to stay in touch with the market and predict and respond to potential trends that will impact our customers and brands. Gallus and Heidelberg have therefore set themselves the goal of being at the forefront of the new digital transformation and driving smart, connected printing to achieve revolutionary levels of production automation and manufacturing efficiency. This is also a response to today's skills shortage and will enable customers to reduce costs and increase both profitability and sustainability. In addition, we have a team in our new Gallus Experience Centre dedicated to exploring new technologies/processes such as artificial intelligence and Industry 4.0 that can be integrated into labels and packaging to inspire and excite future generations.“

Dario Urbinati, CEO of the Gallus Group

To further drive the digital transformation in the labelling and packaging industry and help solve the problems associated with the current shortage of skilled workers and rising costs, Gallus is also introducing a New Heidelberg Customer Portal (HCP) which automates almost every customer contact point. As an absolute industry first, future versions of the solution will also offer predictive functions that utilise artificial intelligence (AI), to provide recommendations for increasing productivity, reducing maintenance costs and increasing profitability. The new platform is expected to save customers up to 35 per cent in time and money on average.

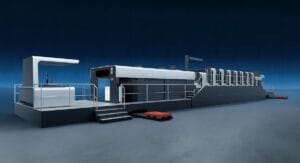

Everything combined in one machine

To further extend the total cost of ownership (TCO) advantage offered by Gallus in label production, the company is also using the event to present the new Gallus One with inline further processing. This solution combines everything inline in one machine and has a digital printer with an integrated flexo station, a semi-rotary die-cutter that can change jobs within a minute and process up to 70 metres per minute, and optical inspection systems that ensure maximum quality and minimise waste.

The company is also announcing the possibility of using an existing Gallus ECS 340 flexographic printing press with a digital printing unit (DPU) and thus convert it into a Gallus Labelfire 340 hybrid press - without any additional investment in a new platform. This means that customers are now able to, combine the flexibility and versatility of digital printing with the reliability and precision of conventional printing and finishing technology.

Source: Heidelberg

Heidelberg - More news

Heidelberg takes over service for Schubert in Brazil

Study shows: paper packaging is becoming significantly more important

Heidelberg acquires technology and trademark rights from Polar Mohr

Networked label printing