To coincide with Ipack-Ima in Milan, GEA is presenting a new packaging system for pasta. The company has redesigned its H-Packer SO Plus to enable pasta manufacturers to process their products faster and with fewer losses. The artificial intelligence with which the system has been equipped plays a special role here.

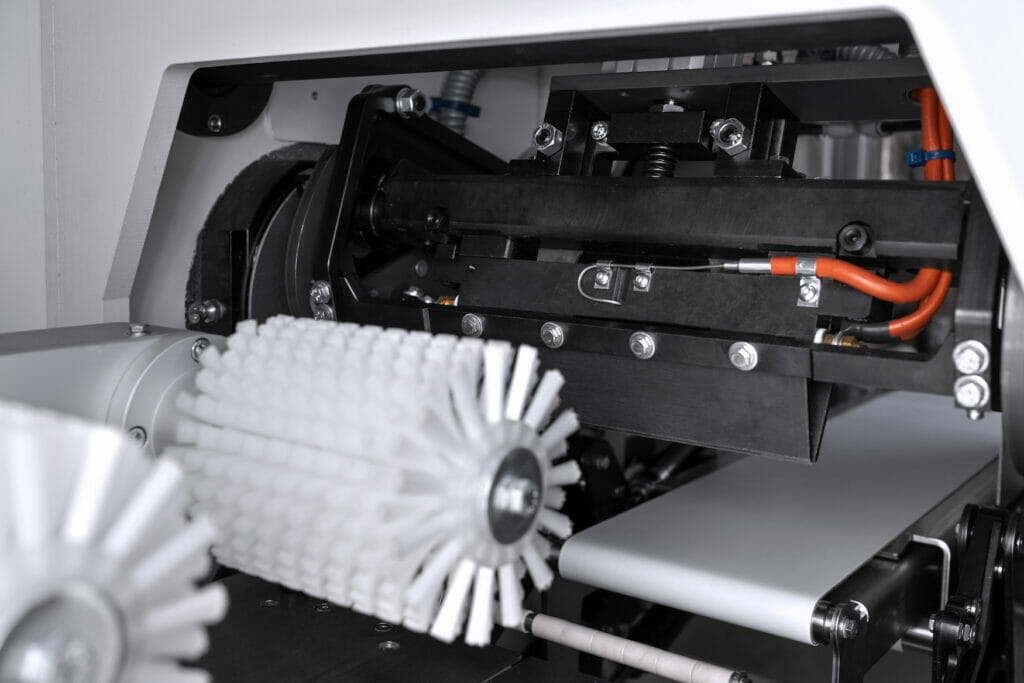

The H-Packer SO Plus is equipped with a second weighing hopper and artificial intelligence in this modified version. A new electronic architecture based on the Siemens PLC offers centralised system control and a Customisable user interface. The new LED lighting for quick visibility of possible faults in the process and a safety device equipped with coded sensors ensure a high standard of safety. In addition, thanks to motorised roll holders, the machine can work not only with conventional plastic films but also with the new paper films. The machine is equipped with a renewed, Patented scraper gripper system completed.

The LC-Doser DDW dosing unit of the H-Packer SO Plus system has been redesigned to optimise the flow of product to the horizontal packaging machine, with a particular focus on flat and rough shapes, and to significantly reduce product breakage. One innovation is a second weighing container, which is installed under the roughing and finishing units and electronically controls the unloaded weight.

Thanks to the use of new patented artificial intelligence technologies, it is possible to adjust the capacity of the discharge boxes to correct any weighing errors and ensure better weighing accuracy. Thanks to the optimisation of this component, the H-Packer SO Plus is particularly suitable for processing flat bronze formats.

The newly integrated electronic architecture is based on programmable logic controllers (PLC) from Siemens, which ensure centralised control of all motors in the packaging system. Operators can control all machine functions from a single HMI panel, allowing for more accurate and faster analyses. Finally, the new integrated electronic design enables a Continuous data exchange between the packaging machines and the monitoring system of the system. In conjunction with the independent brushless motors, this function enables a more even flow of dough and film for visually appealing packaging.

More safety during packaging

The newly designed packaging system is equipped with protective devices with coded sensors and LED lighting. The LED lighting, which is visible throughout the machine, corresponds to the alarm colours, which are divided into zones. As A drop box was integrated as an additional safety measureIt collects all discarded parcels, with or without product, without having to open the machine doors.

The new H-Packer SO Plus is characterised by a further development of the stripper sealing jaw: a new patented movement mechanism, which is controlled via the HMI panel, further increases the operational reliability of the machines, removes the critical components and reduces maintenance interventions and packaging waste.

Source: GEA

GEA at the Ipack-Ima: Hall 1P, Stand B31

More news about packaging machines

Mettler-Toledo shows inspection solutions in Düsseldorf

interpack 2026 shows trends in the packaging industry

White paper | How to make packaging machines more dynamic through lightweight construction

Three applications, one solution