In many manufacturing processes in modern industry, the sterility of packaging, raw materials and materials is essential to ensure reproducible results as well as the quality and safety of the end products. Various processes can be used to sterilise packaging materials. Beta-Gamma-Service GmbH (BGS) focuses in particular on ionising radiation and advises customers on the most suitable technology.

The trend in the manufacture of cosmetic products and foodstuffs towards the avoidance of preservatives also makes effective sterilisation necessary. Blasting treatment has become established for the rapid and cost-effective throughput of large quantities of packaging material: Through a Treatment with beta, gamma or X-rays plastic packaging such as bag-in-box systems (bib), inliners, flexitanks or ampoules, bags, bottles, cans and tubes can be sterilised so that they do not microbially contaminate the product to be packaged. Pathogens such as salmonella in particular are efficiently eliminated even at low irradiation doses of 15 kGy. „We also irradiate closures as well as exhaust valves and limiters such as sliding levers - all in the transport packaging. We never open the boxes,” explains Barbara Schmitz, an expert in sterilisation and disinfection using radiation at BGS, the process.

Advantages of radiation sterilisation

Various processes and technologies are available for disinfection and sterilisation. If sterilisation is established as an outsourced process, treatment with beta and gamma rays is one of the most common technologies. Particularly common is the use of sterilised with gamma rays, and increasingly also with electron beams. X-ray irradiation (X-ray) is at an early stage of development.

Radiation sterilisation is the only process, Sterilise products in the sealed end-of-line packaging without significantly increasing the temperature and without the use of chemicals. Another advantage of radiation sterilisation is the reliable penetration of the materials.

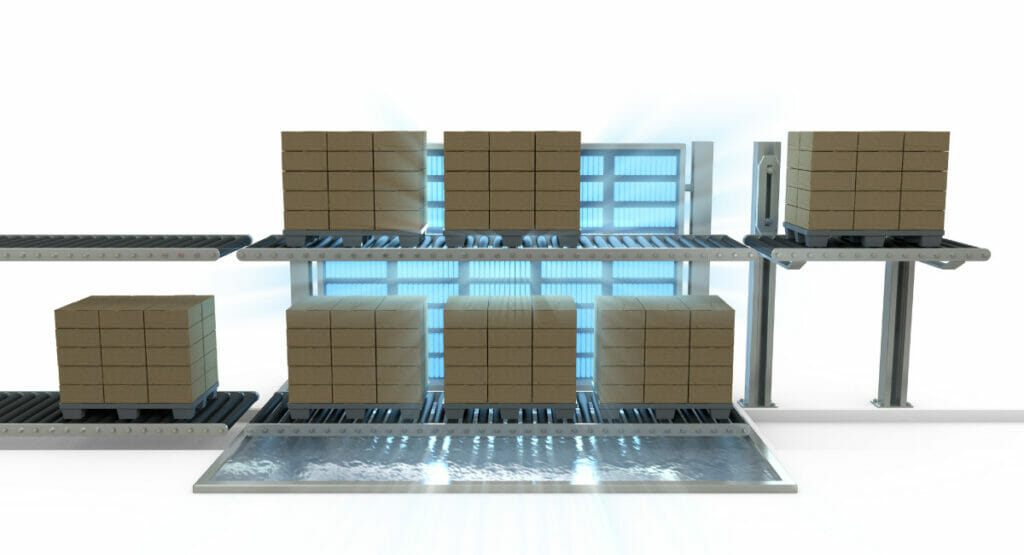

Electron radiation has a high dose rate and a limited penetration depth, whereas gamma radiation has a high penetration depth and a relatively low dose rate. Electron beams are characterised by their ability to, irradiate individual packages within a few seconds. In contrast, irradiation in gamma systems takes several hours. Due to their high penetration depth, gamma rays are able to penetrate entire pallets or containers. „The products to be irradiated can usually be guided through the irradiation process directly on the delivery pallets,“ explains Barbara Schmitz. „The blasting used creates no radioactivity for physical reasons."

If the products are suitable for irradiation, disinfection and sterilisation using electron or gamma rays are a good choice for time-sensitive supply chains. After the irradiation process, the radiation dose applied is checked using dosimeters attached to the product. If everything complies with the specifications, it is immediately released by quality assurance.

Application of radiation sterilisation

Manufacturers who rely on sterility for the filling and packaging of their products should comply with the Pay appropriate attention to the choice of sterilisation process as early as the product design phase. Electron and gamma rays can change the material properties of products, particularly in the case of many polymer materials. This depends on the material itself and the irradiation dose used. This is due to chemical reactions induced by the radiation energy, such as cross-linking or degradation reactions. Some plastics can be irradiated without any problems, others less well or are even unsuitable. Glass discolours under the influence of ionising radiation, whereas ceramics and films behave inconspicuously when exposed to radiation.

Bioplastics such as bio-based PE, PP or PMPr are also increasingly being used in the production of packaging. Compared to standard polyolefins, the material properties of these new, bio-based materials are identical after irradiation. In addition to the selection of a suitable material, the product structure and functionality must also be examined as criteria for the use of radiation sterilisation. Because the complete product is irradiated, radiation sterilisation is also recommended for difficult geometries. The size and quantity of the products also play a role.

Ensure availability with the right process

Choosing the right method is about more than just ensuring that a product is aseptic. One challenge that also accompanies the packaging market for cosmetic products and food is the availability of capacities and the establishment of stable, long-term supply chains. „Manufacturers should therefore Secure capacities at an early stage in order to be able to deliver their products safely to end consumers in aseptic packaging“, advises expert Schmitz. „In addition, back-up processes should be established. This can mean, for example, qualifying the products for a second system.“

More news from the magazine

Sonja Bähr | Packing alone is not enough!

The modern warehouse thinks for itself

Women in Packaging: Committed entrepreneur with team spirit

Smart packaging from conception to recycling