With over 200 submissions from 15 countries, the German Packaging Award 2025, a record participation. 37 solutions convinced the jury. The award ceremony and the announcement of the Gold Awards will take place on 23 September at FACHPACK. packaging journal will broadcast live.

Record year for the German Packaging Award

More than 200 packaging innovations from Europe, Asia and North America competed for the German Packaging Award 2025. 37 entries have now been honoured by the independent jury - with solutions ranging from recycling concepts and technical sophistication to new developments. The competition is organised by the German Packaging Institute (dvi).

Honouring diversity and progress

The award-winning developments cover a wide range of materials - including glass, wood, plastic (rigid and flexible), metal, paper, cardboard and corrugated cardboard. In terms of content, the winning categories reflect key topics in the industry: a particularly large number of awards went to projects in the area of sustainability (14), followed by functionality, design, cost-effectiveness, product presentation, technology, mechanical engineering and the area of young talent.

„We are seeing pioneering solutions and new standards for closed-loop systems, reusability and refillability,“ said dvi Managing Director Dr Natalie Brandenburg. The use of new bio-based materials, intuitive usability, product protection and single-variety recycling were also the focal points of this year's winners.

Innovation in the service of the circular economy

The 37 award-winning packaging solutions come from both the B2C and B2B sectors - including product and shipping packaging, displays, labels, bubble wrap, in-mould labels and technical applications from the mechanical engineering sector. Many of the submissions are aimed at sectors such as food, FMCG, construction, chemicals and manufacturers of solar panels and heat pumps.

According to Brandenburg, the high level of participation proves that the industry is showing innovative strength even in difficult times: „Our thanks go to all the entrants who have made the award a real showcase of achievements,“ she said. The jury had also discussed and evaluated all the entries with great commitment in a two-day meeting.

Award ceremony at Fachpack in Nuremberg

The official award ceremony will take place on 23 September 2025 at Fachpack in Nuremberg. In addition to the presentation of the certificates and trophies, the three particularly outstanding Gold Awards will also be announced there. Participation in the event is free of charge, but registration is required. packaging journal will broadcast the award ceremony as a media partner in a live stream. .

All winners at a glance

packaging journal shows all 37 winners here. An overview can also be found on the official websites packagingprice.com and packagingaward.com.

Category: Design

Jägermeister „Manifest Gift Pack“

Submitter: Mast-Jägermeister SE

Gift wrapping

Jury: The Manifest Gift Pack impresses with a disruptive design that combines aesthetics, functionality and sustainability at the highest level. The innovative choice of material - a biodegradable foam based on natural raw materials - emphasises the ecological claim. Copper and black accents give the packaging an elegant look, while tactile stimuli and digital interaction via a QR code create a holistic brand experience.

A design statement that not only conveys Jägermeister's brand values, but also brings them to life in an impressive way.

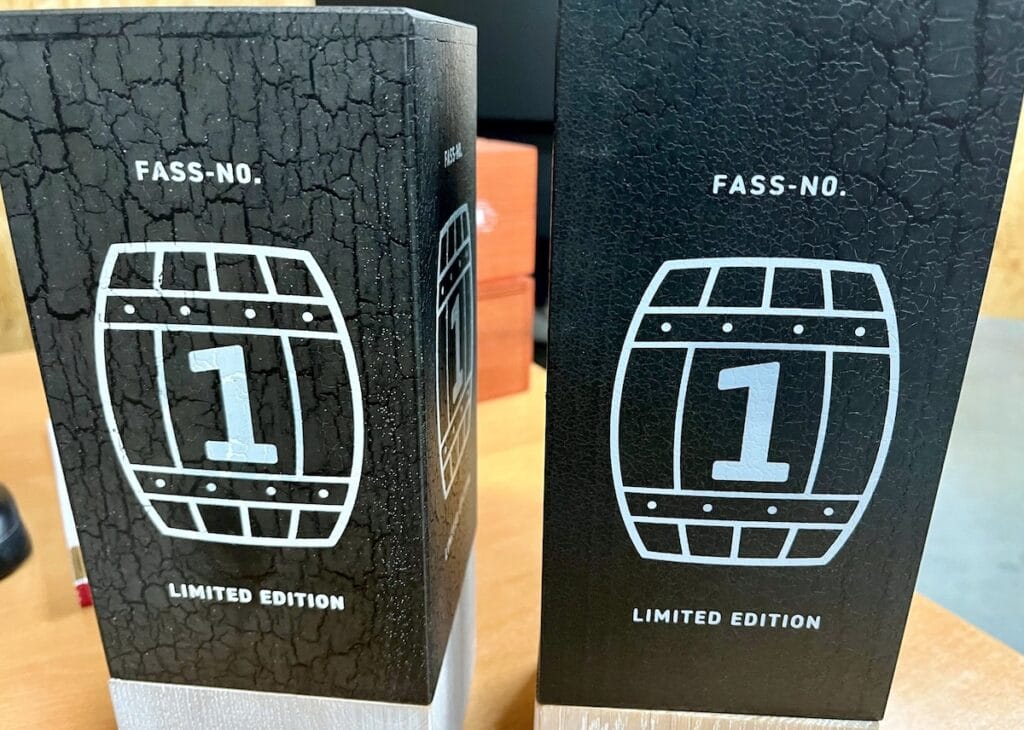

Störtebeker Whisky Cask No.1

Submitter: wertmarke hamburg GmbH

Whisky bottle & whisky packaging

Jury: The self-contained and atmospherically dense narrative surrounding the whisky edition Barrel No.1 and the Störtebeker brand - inspired by the myth of the North German buccaneer - convinced us to honour this submission.

With a keen eye for detail and authenticity, it succeeds in bringing the raw power of the north, the freedom of the sea and the depth of a handcrafted whisky into a harmonious form.

The multi-layered realisation of the brand story, the skilful use of a wide variety of materials and sophisticated finishing techniques create an all-round sensual and harmonious experience.

Not only are brand and product convincingly united here, but emotion, origin and craftsmanship are also transferred into a powerful overall brand image.

CoffeeInteract innovative storytelling

Submitter: Fatemeh Mozafari

Coffee packaging

Jury: CoffeeInteract impresses with an innovative packaging design that uses interactive storytelling to create brand loyalty and rethinks classic coffee packaging. The cylindrical cardboard packaging invites customers to become part of a continuous narrative, the individual chapters of which are only revealed when the respective roast is opened. The packaging is reusable and encourages customers to place it visibly in the kitchen - turning the product into a stylish brand ambassador at the same time. The creative idea is particularly appealing to modern roasteries that want to differentiate themselves through emotional connection and collection potential. CoffeeInteract shows how packaging can go beyond functional aspects to become a brand experience.

Plastic-free glass carafe packaging made from recycled material

Submitter: BLANCO GmbH + Co KG

Protective packaging/ transport packaging/ SIOC

Jury: The well thought-out concept and the harmonious overall appearance of this packaging design convinced the jury. The reduction to a 1c print emphasises the „pure“ element of the glass carafe and leaves room for the essentials. At the same time, the detailed illustration print creates an emotional connection to the product inside.

The deliberate omission of an additional, in this case superfluous shipping box emphasises BLANCO's brand essence: clarity, responsibility and concentration on the essentials.

The unboxing clearly shows that reduction and attention to detail are not contradictory - on the contrary: they complement each other to create a convincing overall concept that has been thought through down to the last detail.

Category: Functionality & Convenience

Blue Star Power Active

MM Board & Paper (MM Plant: MM Frohnleiten)

WC Power Tabs

Jury: The new packaging for Blue Star Kraft Aktiv combines two improvements in one. By switching from a blister consisting of a cardboard card with a plastic cap to a 100 per cent cardboard solution, the packaging is now easier to dispose of and can be recycled. The cardboard is also made from recycled paper, thus conserving valuable resources. In addition, the TOPCOLOR® BARRIER AROMA keeps the fragrance in place without the use of plastic and only disperses it when it should: during use. This means that the fragrance is not unnecessarily dispersed in stores and product freshness is maintained. The combination of these elements makes the packaging a well-deserved award winner.

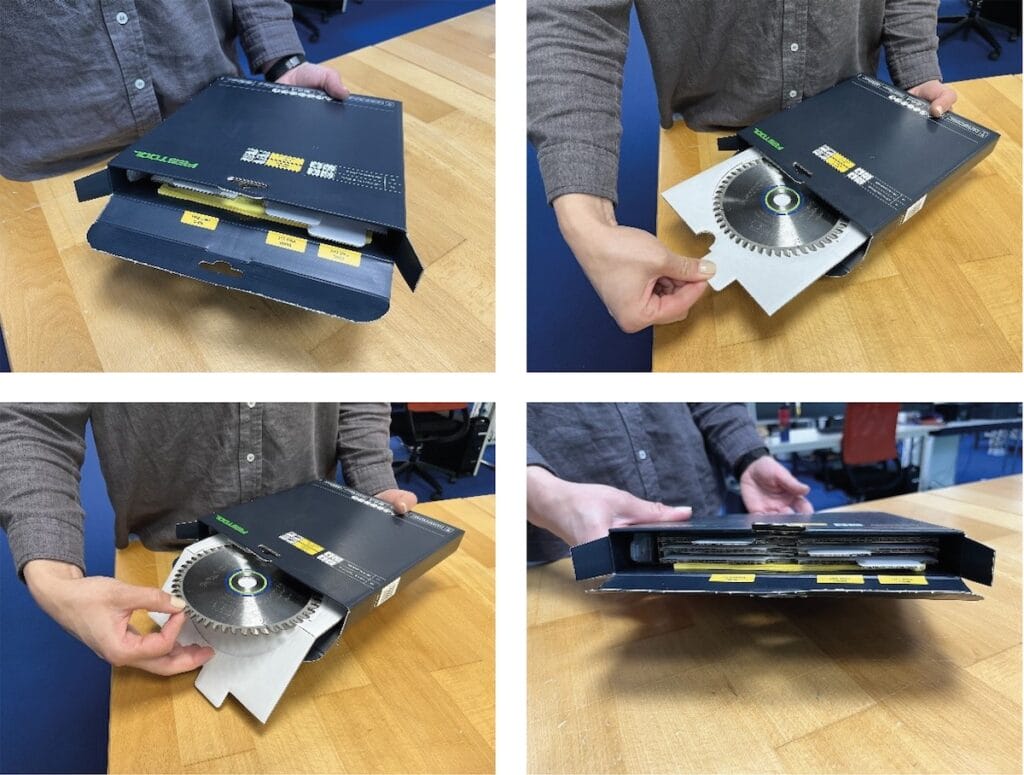

FESTOOL - Mixpack register packaging for saw blades

KOLB Group | Gebr. KNAUER GmbH + Co. KG

Mixpack pendulum packaging with integrated register for saw blades

Jury: The MixPack from Festool impresses as an innovative multi-user that holds three circular saw blades and two sleeves with jigsaw blades safely and neatly.

The sturdy construction combined with a sophisticated design ensures optimum product protection and easy handling.

A clever insert with integrated register enables intuitive removal and clear labelling of the contents. The compact folding box can be used in a variety of ways - as sales, storage and dispatch packaging in e-commerce.

Additional compartments provide space for spare sheets, while the Euro hole supports an eye-catching presentation at the POS.

With its high functionality, robust design and sustainable concept, the MixPack sets new standards for sharp saw blades - and was honoured with the Packaging Award for this.

AeroFlexx Innovative Liquid Packaging Technology

AeroFlexx

Revolutionised liquid packaging

Jury: AeroFlexx impressed the jury with its innovative combination of function and sustainability. It is made of flexible LDPE and therefore requires significantly less material than comparable bottles for shower gels, sauces, etc. and thus actively contributes to reducing packaging waste. The airframe (integrated air cushion) ensures a stable and resistant structure. The unique design, with integrated self-sealing valve technology, enables the contents to be emptied completely, thus avoiding product residues and further waste.

The packaging saves material, reduces transport costs and offers maximum ease of use with its self-sealing valve technology - a pioneering contribution to resource conservation, product protection and customer satisfaction. The packaging is robust and reliably protects the product from external influences. It also shows its strength in the recycling process, as it can be easily reused. Aeroflexx sets new standards for sustainable packaging solutions and therefore deserves the German Packaging Award.

Cake packaging with integrated ring

Delkeskamp Verpackungswerke GmbH

Corrugated cardboard packaging for frozen cakes

Jury: This mono-corrugated cardboard packaging sets new standards: it reliably protects frozen cakes with an integrated ring that holds the cake in place and prevents damage during transport.

The design is one-piece, can be erected by machine and is equipped with clever first-opening protection. The unpacking experience is rounded off by the innovative removal system.

Size and material can be flexibly adapted - turning corrugated board into smart packaging for frozen cakes.

Category: Logistics & Material Flow

Boxli1000 as an IBC replacement for the chemical industry

Evopack GmbH & TRICOR Transport & Logistik GmbH

4-fold logistics and material flow improvement

Jury: The bag-in-box solution presented for large-volume liquid packaging in the chemical industry impresses with its holistic concept for improving handling.

The integrated automatic base in the rigid outer carton makes it much easier to erect, especially as it is an irregular octagon. The bag with the filling and discharge valve is integrated into the lid module, as well as a cardboard layer with eight side flaps. Assembly of the lid module is very simple and torsion-proof, as the cardboard layer with the flaps functions like a funnel.

DACHSER Retail Box

Submitter: DACHSER SE, Kempten

Innovative returnable system for European general cargo logistics

Jury: DACHSER SE was for the development of the „Retail Box“, a new type of reusable system for European general cargo logistics. This innovation enables the environmentally friendly transport of sensitive or high-value goods as a standard consignment via the general cargo network (comparable to a Euro pallet). At the heart of the solution is a lockable reusable container in Euro pallet and Euro half pallet dimensions, which can be used and returned efficiently in mixed operation in heterogeneous general cargo logistics. The Retail Box meets all sustainability requirements by avoiding packaging waste and at the same time optimising processes in shipping and at the point of sale. An innovative digital tracking system ensures transparent and efficient handling. In addition, efficient management of the boxes can be realised via the tracking platform of the start-up Logistikbude in combination with mobile phone systems from Deutsche Telekom. With this reusable solution, goods recipients can be supplied daily within 24 to 72 hours and packaging waste can be significantly reduced (for example, over 4000 kg less for hanging suits compared to disposable systems).

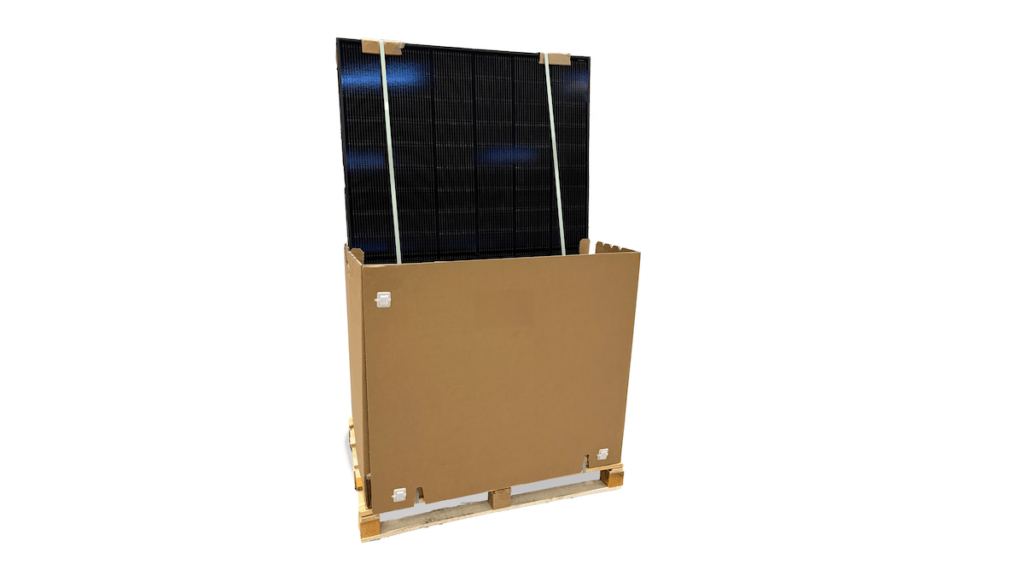

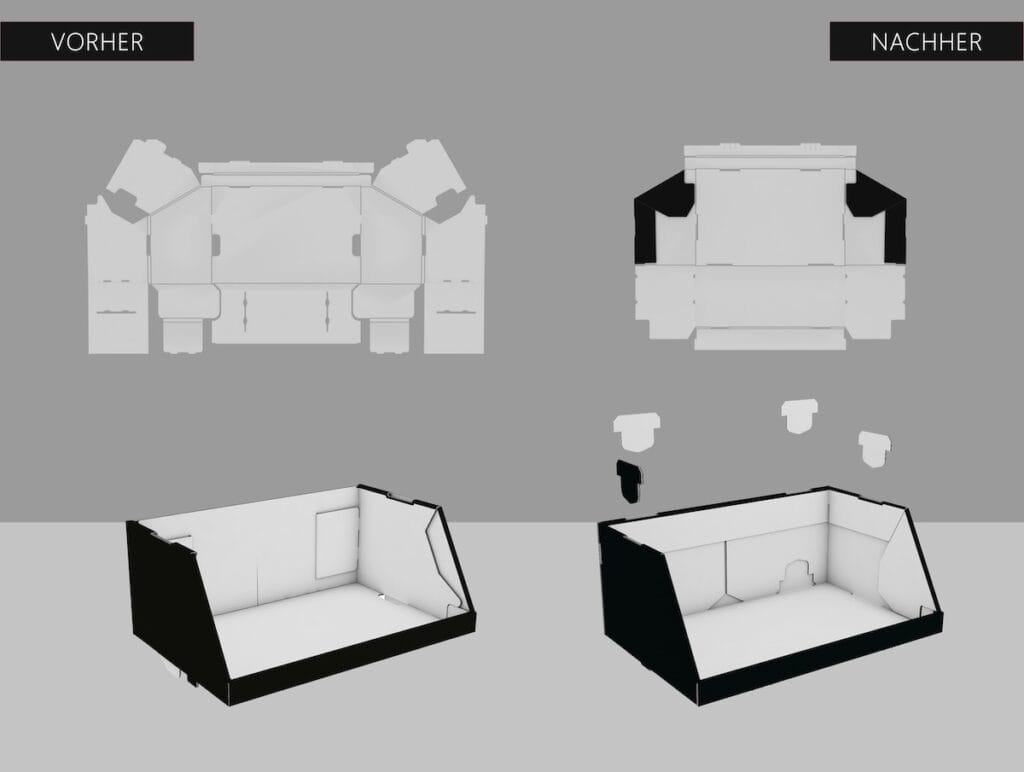

Module packaging for solar panels

Submitter: Smurfit Westrock GmbH

Transport protection, increased efficiency and flexible loading

Jury: In this packaging concept, extensive subject areas were realised in a simple way. The inclined position of the panels and the fact that the front can be folded away make it very easy to pick individual orders. For this purpose, retractable retaining finger strips and push-in fasteners were installed in the outer carton. The integrated option of lashing the modules securely in the load unit enables storage and despatch as a load unit.

Universal upholstery for bench seat systems

Submitter: Mondi Ansbach GmbH

Clever corrugated cardboard cushioning significantly simplifies and optimises the transport of bench components.

Jury: The universal pad from Mondi Ansbach GmbH is an innovative packaging solution for metal components (for bench systems) in the Logistics and Material Flow category. It is multi-variable and has various punched holes that are labelled with letters and numbers. These make it possible to „press“ different combinations of letters depending on the product version, ensuring optimum hold for the respective metal component. The clever arrangement of the recesses allows different geometries to be folded by pressing in and combining different positions, which replaces a variety of packaging materials. Thanks to these properties, the pad reduces the complexity of the packaging process. It is 100% recyclable, reusable and does not require gluing. For this reason, this „one fits all“ approach convinced the jury and was honoured with a packaging award.

aroTHERM Split plus heat pump

Submitter: Vaillant Group / Packaging development

Transport packaging for heat pump outdoor unit

Jury: The new packaging for heat pumps shows how clever product protection and sustainability go together perfectly. By optimising the design and material, the C02 footprint of the packaging is reduced by 60 % - without compromising on protection.

Thanks to the reduced pallet size and optimised padding, more goods fit on the truck and in the warehouse: up to 30 % more appliances per truck and 25 % less packaging volume overall. This saves space, lowers transport costs, conserves resources and reduces emissions.

This innovative packaging concept makes a measurable contribution to climate protection and significantly increases efficiency along the supply chain.

Category: Sustainability - Overall concept

Kallfass-Wrap®

Submitter: Kallfass Verpackungsmaschinen GmbH

Food packaging

Jury: The Kallfass wrap is a sustainable packaging solution for fresh food that intelligently combines both ecological and functional requirements. A tray made from renewable raw materials is wrapped in a wafer-thin barrier film and sealed airtight. Protective gas can optionally be used to extend the shelf life.

The innovation impresses with its consistent focus on saving materials and conserving resources. Particularly noteworthy is the forced separation of tray and film when opening, which enables simple and unmixed disposal - an important contribution to improving recyclability. At the same time, the system ensures a high degree of flexibility in the tray size and therefore a wide range of applications for different products and market requirements.

The jury recognised this solution as a pioneering step towards more sustainable packaging in the food sector - resource-saving, recycling-friendly and versatile.

Resource-saving lacing

Submitter: Siebeck GmbH

Plastic-avoiding, energy-efficient packaging with sustainable packaging material

Jury: As an alternative to classic plastic strapping, the solution from SIEBECK GmbH uses pure or recycled cotton cords and wood fibre cords.

The innovative mechanical knotting of the belt can be opened by hand - and therefore without tools - if required, as the usual welding of plastic belts is no longer necessary.

The combination of the use of renewable raw materials and reduced energy consumption makes a special contribution to CO2 savings.

VpCI film with recycling concept

Submitter: Jakob Schober GmbH

Temporary corrosion protection in shipping packaging

Jury: The award recognises the outstanding achievement of Jakob Schober GmbH and its partners in creating a „closed-loop system“ for their innovative VpCI corrosion protection film.

In cooperation with the partner company EcoCortec, the first step was to develop a new VpCI film that is now recyclable and contains 30% PCR (post-consumer recyclate).

In a second step, a recycling system was set up with European customers to collect and return the VpCI films after use. To this end, the logistics for our own new products are also used for the return transport. The used VpCI films are then recycled and reintroduced into the cycle as PCR content in new films.

Many people talk about closed loops for packaging, but Jakob Schober has also demonstrated it in practice with customers and partners. This is impressive and deserves to be honoured with the German Packaging Award.

BULA Popo flower foam pump

Submitter: Thomas Kriz, Anilex GmbH (BULA)

Patented flower foam pump for mechanical dispensing of BULA foam onto toilet paper as a replacement for environmentally harmful wet wipes

Jury: Even if the packaging solution used is not fundamentally new in its kind, the coherent and holistically conceived overall concept was convincing.

The BULA Popo fluff foam pump replaces classic wet wipes with a consumer-friendly and refillable solution in combination with commercially available and fully recyclable toilet paper. The result is a hygienic alternative that is suitable for everyday use and conserves resources. Compared to conventional wet wipes, BULA avoids up to 6 kg of waste per household per year, saves transport volume and reduces CO₂ emissions.

The solution is exemplary for functional sustainability - combined with an emotionally appealing design and high suitability for everyday use for private and professional applications.

Category: Sustainability - Material substitution

Fibre Box - BEYOND THE CATCH

Submitter: PAPACKS Sales GmbH

EPS box replacement for cool boxes Seafood

Jury: The PAPACKS Fibre Box is a sustainable alternative to EPS boxes for the fishing and food industry, ideal for fresh and chilled products. It has been specially developed to replace conventional EPS packaging with a 100% recyclable, biodegradable and stackable solution. The FiberBox is based on hemp and tree fibres and is equipped with a natural barrier coating, has excellent insulating properties and can also be completely disposed of in waste paper recycling. As a 1:1 replacement for EPS boxes, it can be used along the entire value chain - from fishing to retail - and actively contributes to plastic reduction and the circular economy.

re/cycle CompressWrap - paper-based mattress packaging

Submitter: Mondi

Paper-based packaging solution for compressed mattresses - recyclable and safe to transport

Jury: The CompressWrap is a paper-based roll packaging for compressed mattresses

Mondi's re/cycle CompressionWrap is a paper-based packaging solution that replaces plastic packaging for compressed mattresses with paper as a recyclable, fibre-based material. The solution consists of two functional paper layers: a high-strength inner layer with a thin barrier coating (ratio 95/5) ensures that the mattress can be packed vacuum-tight and dimensionally stable, which saves a lot of transport volume, while a second outer layer provides protection against mechanical influences. The packaging solution is designed so that it can be integrated into existing production systems.

Two separate submissions, two prizes, same performance

1: Otto tests shipping carton made of paludi (bog plants)

2: Plant transport cardboard made from waste paper and 10% fibres from Paludi biomass from rewetted peatlands

Submitter: Otto GmbH & Co. KGaA and LEIPA Group GmbH

1) Test of paludi-plants (from the moor) for shipping cartons to promote the rewetting of moors.

2) Development of a fibre made from Paludi biomass to reduce CO₂ emissions, promote biodiversity and implement sustainability communication

Jury: The shipping carton for Otto and the plant transport carton from LEIPA & OBI were both manufactured with a proportion of 10 % Paludi fibres in the corrugated base paper and cardboard respectively. Paludi describes plants and grasses that grow on wet moors. The commercial use of Paludi fibres is intended to promote the rewetting of drained peatlands in order to reduce greenhouse gas emissions, as 7 % of total annual CO2 emissions in Germany alone come from drained peatlands. The technical properties of both types of packaging were not affected by the addition of the Paludi content, nor was their recyclability. With this award, the jury recognises the pilot projects of the toMOORow initiative to generate new plant fibres for paper production and at the same time bind greenhouse gas emissions through the use of Paludi plants.

Category: Sustainability - bioplastics and renewable raw materials

AquaWave water-soluble paper air cushions

Submitter: Flöter VerpackungsService GmbH

Air cushions for more sustainability in e-commerce

Jury: In addition to the primary use of protecting products during shipping, this submission also focussed on the post-use phase during development. The material fits into the paper recycling stream thanks to a combination of 100% waste fibres and a water-soluble PVA coating that dissolves within a very short time. The recovered paper fibres are not contaminated.

The jury was impressed by this end-of-life development, which is already on the market.

Category: Sustainability - Use of recycled materials

Oil canisters with LDPE from beverage carton recycling

Submitter: Saperatec GmbH, AF Color and Palbo GmbH

Blow-moulded canister for non-food contents

Jury: If you want to tap into new sources of recyclate, you have to think outside the box. Palbo GmbH, together with Saperatec and AF Color, has done just that. LDPE coatings for beverage cartons are now also being turned into PCR for HDPE oil bottles.

The process for manufacturing the HDPE oil bottles was optimised in collaboration, so that more than 50% PCR LDPE is now used for the extrusion-blown bottle. Another smart approach is that the manufacturer of the colour granulate was involved in this project, who also uses the PCR LDPE as an ideal carrier for the colour masterbatch, which further increases the PCR content of the bottle.

This cooperative effort and the creative use of PCR plastic types in atypical areas of application is honoured and receives the German Packaging Award.

Dairy scoop with 30% mechanical polystyrene recyclate

Submitter: Müller Service GmbH

Cups from the dairy sector

Jury: The dairy scraper with 30 % mechanical PS recyclate demonstrates an innovative application of recyclate in the food sector. It promotes the high-quality recycling of PS material, which is now given a new lease of life instead of disappearing into downcycling. This reduces the use of virgin PS material and conserves resources. With the goal of a circular economy in mind, the jury believes that this CO2-reducing application is a honourable step forward!

Recyclable stand-up pouch with recycled content

Submitter: Werner & Mertz GmbH and Mondi

Stand-up pouches for detergents, cleaning agents and cleaning products as primary and refill packaging

Jury: In this award, the focus was not only on the use of recyclate as an innovation for a stand-up pouch for liquid contents, but also on the fact that a specially developed recyclate was not used. An existing material from the Yellow Bag, which is obtained from the existing sorting and processing infrastructure, shows that secondary materials are already available for flexible packaging from household collection. The film structure is adapted to the recyclate.

Category: Sustainability - Recyclability

PP mono-material packaging for RTD coffee

Submitter: Molkerei Gropper GmbH & Co. KG

PP cup for ready-to-drink coffee

Jury: In the Sustainability category, we honour packaging that shows how well thought-out design, material intelligence and user orientation can merge into a genuine innovation.

The „PP mono-material packaging for RTD coffee“ from Molkerei Gropper GmbH & Co. KG sets new standards in sustainable packaging development. At its heart is a cleverly integrated in-mould label that completely replaces the classic aluminium plate. This IML takes over the function of the first opening, remains on the lid after opening - and, like the entire cup, is made of pure polypropylene.

This solution not only improves the user experience, but also enables the entire packaging in the PP fraction to be recycled by type - a real contribution to the circular economy.

The production process is also impressive: the cup and lid are joined using energy-efficient ultrasonic welding, which does not require adhesives and increases product safety.

The packaging is already ready for the market, and we wish the Gropper dairy every success and good luck with the upcoming market launch. This innovation deserves to be on the shelves - and in the hands of conscious consumers.

Mono-material PP stand-up pouches from Hengstenberg GmbH & Co. KG with composite film from Wipf AG for cabbage products and pasteurisation of acidic products.

Submitter: Wipf AG / Hengstenberg GmbH & Co. KG

Specially developed composite film from Wipf AG for pasteurised, acidic products with a shelf life of two years.

Jury: The stand-up pouch for sauerkraut is a pioneering packaging solution that combines recyclability, product protection and consumer friendliness at a high technical level. The bag consists of a mono-material composite and is therefore extremely recyclable - despite the special requirements that the acidic environment of sauerkraut and the necessary filling and preservation processes entail.

The packaging can even withstand the high temperatures of pasteurisation and ensures a remarkable product shelf life of up to two years. In addition, the pouch is designed so that it is also suitable for heating in the microwave - a clear advantage in terms of convenience and versatility.

The jury was particularly impressed by the combination of sustainable use of materials with the demanding functional requirements of a sensitive food product. This solution is an example of how modern packaging can combine ecological responsibility and technical performance.

Category: Young talent

FIXMATE

Submitter: FH Münster / Münster School of Design (MSD)

Marie Erdbrügger, Kaja Pielage, Meret Wichmann, Rebecca Jessulat

Bicycle repair kit

Jury: FIXMATE replaces classic plastic repair kits for bicycles with a compact, intuitive cardboard solution. Tools, spare parts and clearly illustrated step-by-step instructions are functionally combined in a clearly organised packaging system. The instructions are printed directly on the packaging, eliminating the need for separate inserts and significantly simplifying use. The design allows easy attachment to the bike or space-saving storage - ideal for travelling. FIXMATE reduces the use of materials and complexity in equal measure and shows how packaging can provide targeted support and guidance.

Padon

Submitter: FH Münster / Münster School of Design (MSD)

Bahareh Hosseinzadeh Alamdari, Birte Müller, Meret Fischmann, Jule Schelletter

Clever, sustainable packaging and storage for sanitary towels that make handling easier

Jury: The taboo subject of „period hygiene“ is solved here with great freshness and, above all, very cleverly in terms of structure.

Functionally, the concept is based on the principle of the ‚Magic Wallet‘ and is made from folding boxboard in a one-piece blank.

The sanitary napkin, which is in a plastic-free individual pack, can be removed from the opened folder and when the folder is opened upside down, it provides secure storage for a used sanitary napkin. This packaging creates real added value, especially for places where a quick, hygienic solution is required.

Category: New material

kp 100% Tray2Tray® - first-to-market material

Submitter: Klöckner Pentaplast

The product is a tray for fresh protein made from 100 % recycled PET trays. We are submitting kp 100 % Tray2Tray® in the „New Material“ category as it is the first of its kind to be launched on the market.

Jury: This is the first packaging material on the market that is made entirely (100 %) from recycled food thermoformed trays and not from bottle waste. The result is a new material stream that enables food-grade mono-material rPET - made for trays from trays - and thus closes the loop without downcycling. RecyClass certification for closed-loop recycling with recyclability class A was achieved.

Category: Packaging machines

ILLIG Dry Fibre Systems

Submitter: ILLIG packaging solutions GmbH

Production system for the manufacture of fibre-based packaging

The jury was impressed by the forming ratio of up to 1.5 that can be achieved under optimised conditions, resulting in remarkable, prototypical, fibre-based solutions from the dry state. With such a forming ratio, the production of commercially available containers beyond flat trays can also be realised in paper. The development work carried out and still to be expected in the machine technology used and the contribution to future sustainable packaging solutions is particularly worthy of recognition.

Category: Product presentation

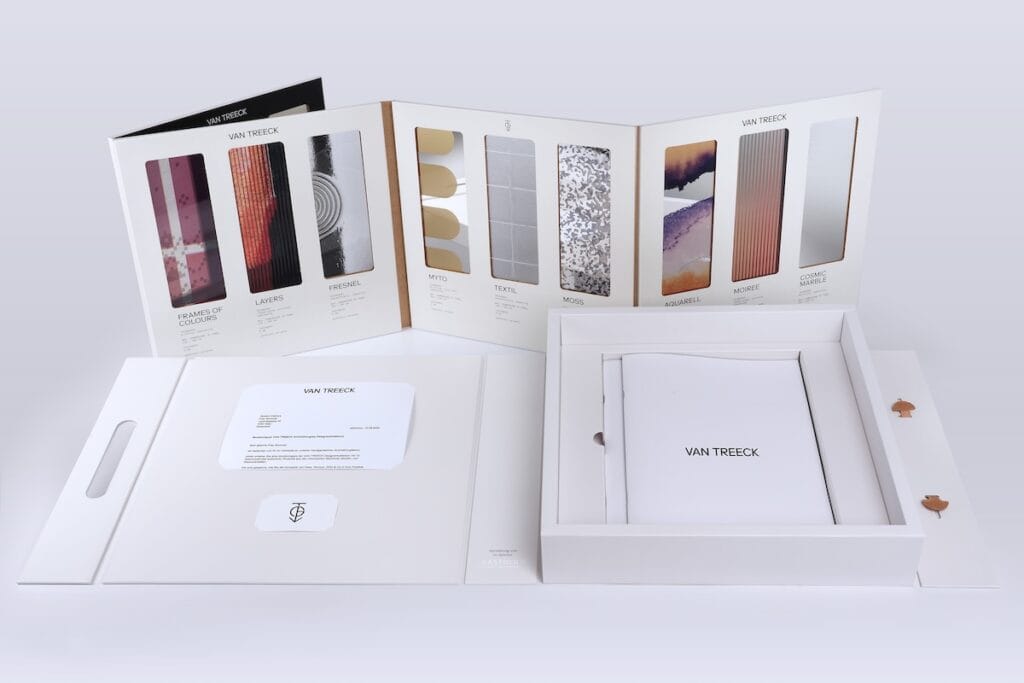

Sample case with screen (architectural glass)

Submitter: Markus Hartl, Kastner AG

Carrying case with product presentation for sales

Jury: The customised carrying case sets standards in product presentation for glass, wood, carpet or tiles and has a compartment for brochures as well as a map and business card in the lid. A screen with 12 different types of glass, which is set up using a satin ribbon, makes for an impressive presentation. The case impresses with its functionality, stability and attractive design. Made from sustainable materials such as corrugated cardboard, grey cardboard and tear-resistant kraft cardboard, it is also environmentally friendly and robust. The front and back are finished with a spot varnish and a matt, scratch-resistant cellophane coating.

Molton Brown Christmas 2025 Limited Edition Fragrance Bauble

Submitter: KAO Germany GmbH

Scented ball - a joyful, decorative gift idea that can be hung on the Christmas tree

Jury: The limited Christmas edition 2025 is outer packaging and display in one. It impresses with its strong, conceptual design.

It expresses luxury and puts the perfume in the best light without compromising on sustainability.

The removable cord and the easily detachable info back make it an outstanding Christmas tree decoration that can be hung between the baubles on the fir tree. The light shines elegantly through the flacon in its luxuriously refined cardboard passe-partout.

Bread shelf

Submitter: Bäckerei Gut Wulksfelde / design for human nature

Bread shelf for the presentation and self-service of organic bread in food retailers

Jury: The bread shelf in the iconic spike shape impresses with its strong design anchoring in the origin of the product: Gut Wulksfelde grows its own grain and processes it in its own bakery - this narrative is also reflected in the packaging at the point of sale. Made from natural Nordic wood, the shelf not only offers a high-quality materiality, but also an ergonomic, clearly structured presentation of the bread varieties. Particularly noteworthy is the intelligent shelf inclination, which allows the bread to slide automatically and remain neatly in view of the customer at all times. The modular customisability, integrated lighting and easy cleaning make the concept both functional and flexible. A successful example of how packaging in a space can become a brand-building communication area.

Category: Economy

Multi-page wet-glue label

Submitter: KilianDruck Grünstadt Dinges GmbH

Labelling in several languages in a limited space

Jury: Killian Druck presents the revolution in wet-glue labelling: multi-page labels for all types of containers. Up to five pages of information on one label, without converting existing machines. No more double labelling, material consumption is reduced by up to 50%. More sustainable, more efficient and easy to implement. More information on less space - a new standard in product labelling. Innovation for more sustainability and communication.

Disc Safe - Brake disc packaging

Submitter: Smurfit Westrock GmbH

Product protection incl. CO2 and cost reduction

Jury: The Disc Safe is an outer packaging for car brake discs. A brake disc is individually packaged and then bundled in a transport box with other individual packages and then transported on a Euro pallet. Previously, a two-part solution in 5 different sizes was used for 230 different types of brake discs. The new packaging is now a material-saving one-piece construction with a cushion that holds the brake disc securely in place. The new packaging enables a significant increase in the number of units per transport crate and thus reduces transport effort, CO₂ emissions and costs. This well thought-out concept convinced the jury due to the clear advantages for the environment and logistics.

Material-optimised stacking tray

Submitter: STI Group | STI Gustav Stabernack GmbH

Corrugated cardboard stacking tray - suitable as a shelving unit or display structure.

Jury: The new, pre-glued cardboard tray for Coty is characterised by an optimised design and improved logistics. Previously, the company used large-format corrugated cardboard trays, which were delivered on special pallets (120 x 160 cm) and assembled manually. This solution has been replaced by a pre-glued, more compact corrugated cardboard tray, which is delivered on standard returnable pallets. This reduces the transport volume by 22.5 %, the weight and material usage of the trays by 23 %, the CO2 emissions by 18.2 % and the packing time for the co-packer from 50 to 30 seconds per tray.

As the back of the tray is folded inwards in the new tray design, this area can be designed at no extra cost and used to support sales. Additional transport stability is provided by T-shaped insert elements, which are positioned in the die-cut waste and to which the trays can be easily connected. In addition to the savings achieved by the new concept, the jury was also impressed by the additional design and placement options.

A look back: Talk about the best packaging of the year 2024

Prize ceremonies and awards - More news

German Sustainability Award: Leef and Traceless are among the winners

Amcor is looking for innovations

Product innovation in Glass 2025: these are the winners

These are the winners of the Corrugated Board Austria Awards 2025