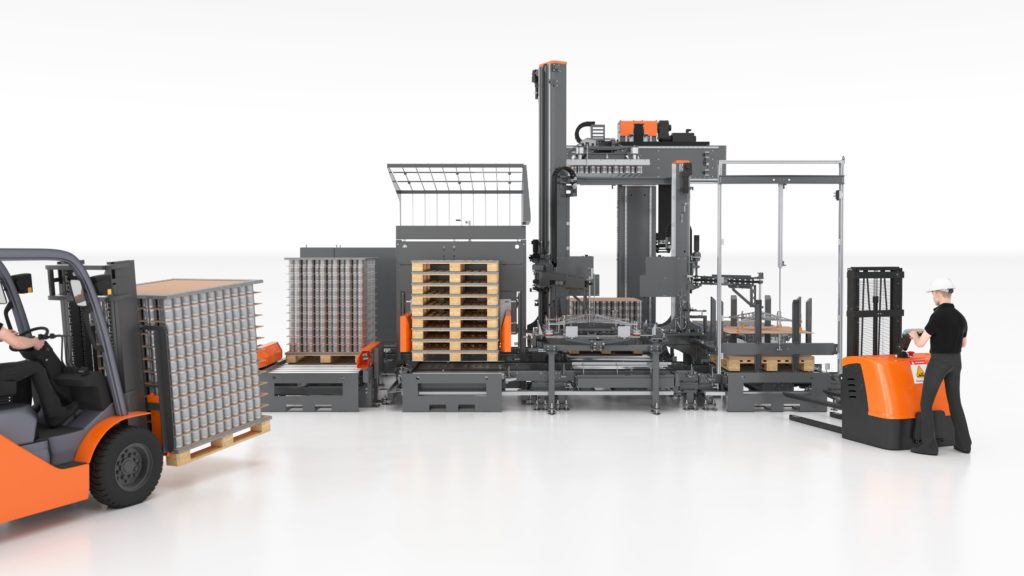

The new layer depalletiser in Trapo's HLDP series offers ground-level depalletising of empty cans and jars with a capacity of up to 90,000 pieces per hour.

The high-performance layer depalletiser (HLDP series) from the Trapo AG enables ground-level operation thanks to the space-saving arrangement of the modules. Thanks to its modular design, the HLDP analogue also glasses and bottles handle.

The HLDP does away with the usual second operating level using a platform - an absolute safety plus in this performance class.

The solution impresses with the use of a lifting column in combination with a magnetic or vacuum gripper and thus enables the efficient depalletising of empty cans (tinplate / aluminium) or empty jars - with an output of up to six layers per minute. This corresponds to around 1,500 empty cans per minute.

The depalletising line makes it possible to pick up a complete layer of empty cans or empty jars of different sizes and shapes on pallets up to three metres high and place them in a single work step. Can be safely depalletised as a complete layer and give up.

The metal pallet stacking frame forms the Optimum transport protection for loose products like empty tins. Applied at the end of each layer, they create fully-fledged transport units that are ideal for stacking. In the first depalletising step, these reusable pallet collars are removed by a magnetic gripper and placed on an empty pallet to save space.

Ground-level depalletiser for empty cans

This is followed by the core task of depalletising empty cans: A Magnetic gripper with integrated pneumatic magnetic plate for maximum holding force holds the entire layer of cans including the stabilising cardboard intermediate layer.

The magnetic gripper enables energy-efficient and reliable handling of ferromagnetic workpieces. The permanent magnet is moved by a pneumatic system. This enables it to securely grip the workpieces - in this case empty cans - and place them down again in the best possible way.

In a third step, a downstream vacuum gripper removes the stable cardboard intermediate layer that protects the layers of cans on the pallet from external influences. These are also stacked and staged in a magazine.

The magnetic gripper transports the empty containers safely onto the conveyor belt so that they can be transported onwards for filling. The following are depalletised All common pallet formats (Euro, industry, Chep, etc.).

For empty glass, the Magnetic gripper replaced by a vacuum surface gripper. The advantage: broken glass remains on the layer pad and is avoided during production. It is automatically removed from the layer pad and collected in a safe container.

Source: Trapo Ltd.