Under the motto ‚We turn ideas into solutions‘, Handtmann, manufacturer of process technology for food processing, will be showcasing the latest technologies for the production of a wide range of food products at this year's Anuga FoodTec. The spectrum of modular company solutions ranges from start-up applications to fully automated, highly industrialised high-performance production.

The highlight of this year's trade fair is a new Complete solution that covers all process steps from the filling and portioning process to insertion into the packaging from a single source. Vacuum filler, filling mincer, FS 525 moulding system, retraction conveyor, tray denester and infeed conveyor, including the new advanced version of the WS 910 digital weighing system, form a fully automated production process with maximum flexibility for a wide range of products and tray formats.

In the area of Product preparation the Handtmann Inotec BC140iT-300 automatic processing machine and the VarioMix mixer will be on show. These universal process units can be used for the simultaneous heating, cooling, mixing, crushing and emulsifying of solid, pasty and liquid products. The all-rounders can be used as stand-alone machines, but are also easy to integrate into modern, complex production processes.

Convenience solutions

For the areas Snacking and convenience different solutions for Moulded products from various applications such as meat and meat substitutes, dairy, bakery and confectionery, vegan-vegetarian or pet food.

The MSE 441 and MFE 431 manual moulding units, which can be attached to the Handtmann vacuum filler in just a few simple steps, will be on show for the automated manual production of a wide range of moulded products. The newly developed VF 810 vacuum filler with FS 521 moulding system is available for medium and industrial output capacities, as is a complete system consisting of the VF 838 S with integrated GD 451 filling grinder and the 6-24-band FS 510 moulding system.

Dosing with Handtmann

When it comes to dosing, the filling and portioning specialist offers a wide range of solutions, including the new dosing valve DV 85-1 for dosing dips and sauces, soups, meat salads, desserts, toppings, mixes, shortcrust pastry, spreads and pasty pet food products accurate to the gram. Can be used directly in various containers such as cups, bowls, thermoformed packs and jars or as toppings.

The DV 85-3 model also has a Large variety of products given by product masses in the consistency of very liquid, pasty, inhomogeneous, lumpy, fibrous, large deposits or high liquid content. Hot filling is possible up to 90°C. Dosing pistons in various designs further extend the range.

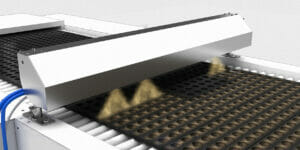

The DS 552 dosing system will also be demonstrated for the Direct, multi-lane dosing of a wide variety of product masses in thermoformed packaging, trays, on conveyor belts or dough belt systems. The automatic dosing process takes place flexibly on 2 to 24 lanes at an industrial high-performance level. The dosing principle with suck-back, without filling pistons and valves, doses liquid to viscous fillings accurately to the gram and with process reliability.

Another focus of the trade fair will be the new Customised Solutions. Founded in 1954 as Albert Handtmann Maschinenfabrik, the company offers customised solutions for individual customer requirements - from product preparation to the filling, portioning, dosing or forming process through to packaging solutions.

Handtmann at Anuga FoodTec 2022: Hall 6 Stand B010/C019

Source: Handtmann

More news about Anuga FoodTec 2022

Mondi at Anuga FoodTec for the first time

Wrap pizza and enjoy pizza

Flexible labelling and inspection

Dosing dips and sauces