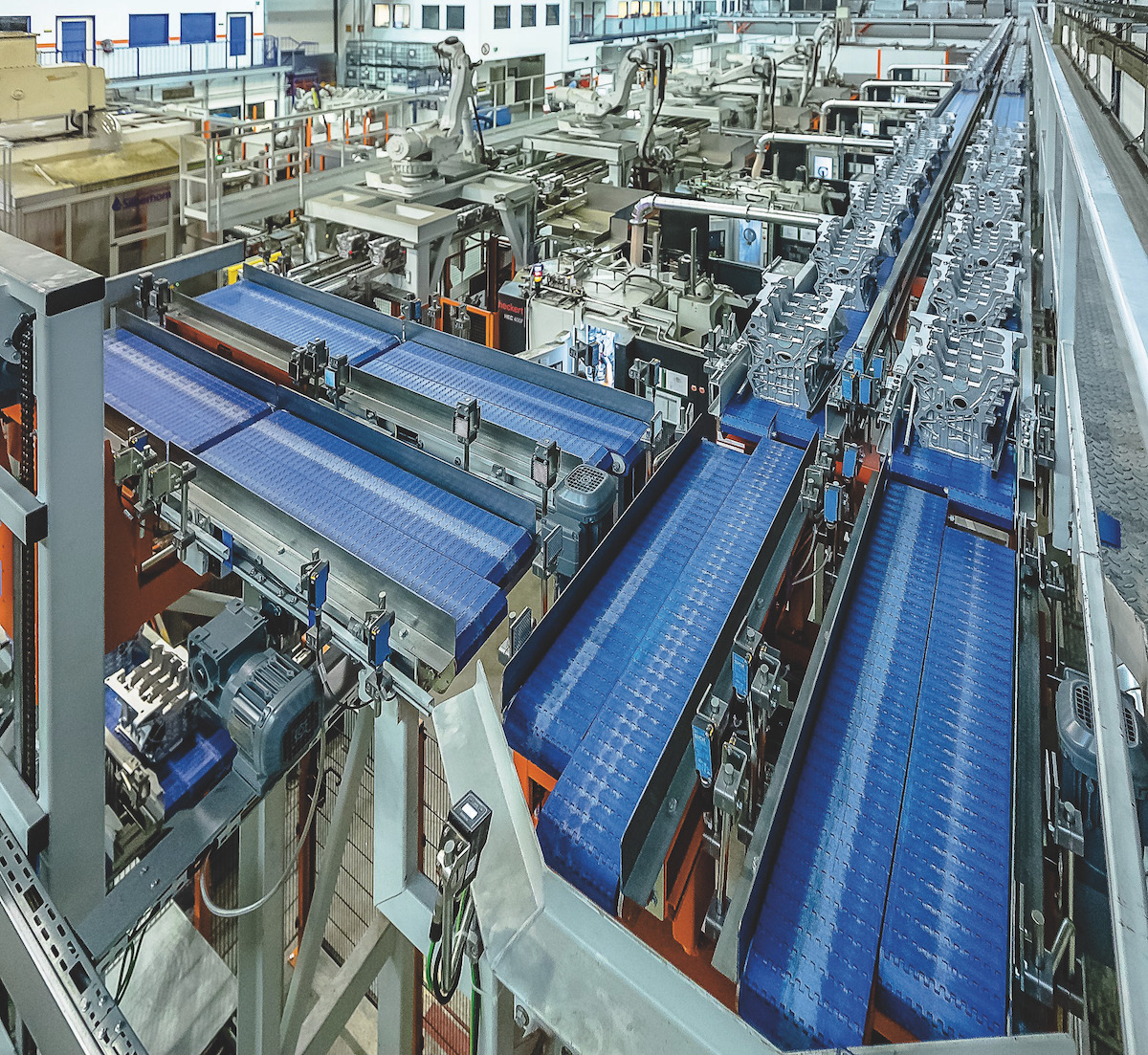

Conveyor technology is of central importance for the smooth flow of materials in companies. Depending on the task, it pursues different objectives. For example, the optimum utilisation of available space plus time savings, flexibility, speed and individuality play a significant role in a wide range of industries with varying degrees of importance.

Years ago, this was still the case at HaRo Anlagen- und Fördertechnik GmbH: parts for production were collected from stacks of boxes. Today, this is done by smart, intelligent control systems with transport to the destination using conveyor technology. This also sets Smart solutions for storage and intralogistics ahead.

An automated process is used to store and retrieve stock quickly and precisely. This was preceded by a Meticulous analysis of the current situation ahead. This was the only way to optimise material management. It was clear that all stored goods had to be classified according to size, weight and frequency of call-offs.

In practice, the least required goods are often stored in the most remote locations. This results in considerable additional costs to get the goods from A to B. This is why HaRo's material management system places great emphasis on Integrated universal complete solution laid. As not all materials can be handled like small parts, the raw material for the production of the rollers is stored where they are manufactured. This is because the individual parts required for system production vary in terms of dimensions and design.

Nevertheless, production runs smoothly as all logistical steps are cleverly planned and internalised. The individual conveyors of the overall system are produced precisely on time for the dispatch date. This means that the assembly of the system can be completed quickly and without disruption to the customer.

About the analysis of the project

Before the HaRo specialists start thinking in terms of conveyor elements, the first step is to Comprehensive analysis on site created. Based on the customer's objectives, details are determined that enable a realistic concept to be developed. A seemingly endless catalogue of questions ultimately drives the solution for a successful concept.

Qualified experts plan presentable concepts from the complex data material. Brainwork is required to create smart ideas from the specifications. The engineers are supported by CAD systems, which display the ideas on the monitor in a 3D version. Databases with components simplify the work.

In intermediate steps, the combined elements are repeatedly checked for plausibility and final interaction. Per 3-D animation runs through the planned system in its entirety and any weaknesses are revealed. After this „maiden voyage“, the concept is presented to the client. Minor corrections keep the effort involved within manageable limits.

This practice is standard at HaRo and has proven itself in numerous successfully completed projects. For example, at Ritzenhoff, a company world-famous for its glassware. In nearby Marsberg, the Transport of 60 pallets per hour from top to bottom, to the very bottom for further processing and from there to the commission warehouse or back to the first floor.

Vertical conveyors were designed and used for this purpose. In addition, a large vertical conveyor was to be used to transport forklift trucks from one floor to another. Following the installation of various modules such as roller conveyors, pallet lifting stations and vertical conveyors as well as cross transfer carriages, rotating platforms, eccentric lifters and chain conveyors as well as a vertical conveyor plus transfer carriage and buffer section, everything is organised in an orderly fashion after the „intervention“.

Well-organised production management

At HaRo, everything runs according to plan, computerised and monitored. Where others rely on SAP or comparable software, HaRo uses a Well-functioning ERP system and an equally Proven MES system. The ERP system forms the basis for the complete control of all functional areas in the company, which are installed as individual modules. This means that every authorised function holder can see in detail what is happening in their own and neighbouring areas.

What's more, in view of increasing efficiency and consciously protecting the environment, HaRo sees itself as a „paperless office“. HaRo has not used paper filing systems for years. Instead, business transactions are „parked“ on high-performance servers using a well-structured and precisely defined folder system. This means that paper can be (almost) completely dispensed with. If the ERP system accesses the planning of available resources in the company, the MES then takes over the detailed productive work in real time.

The system is used to optimise production within the Process automation managed, guided and controlled. This also includes classic data acquisition such as PDA, which has a direct impact on the production process. The MES has long since made a name for itself in terms of controlling the implementation of the specified planning and the directly associated feedback from the ongoing process.

Varied product range in a modular system

Flow rack storage systems, lifting tables, chain conveyors, hinged passages, roller conveyors, transfer cars, belt conveyors, vertical conveyors, pushers, ball roller tables and roller conveyor curves as well as turning stations keep operations running. The variety can already be seen in the roller conveyors. Depending on the transported goods and customer requirements, the Individually set role divisions become.

If, for example, only small goods need to be transported, the SFR„ roller conveyor system“ with the narrowest roller pitch. Idlers with a radius of 60 millimetres and a pitch of 66.6 millimetres between the idlers are used. Loads of up to 800 kilograms per metre can be handled.

Roller conveyors with large pitches, on the other hand, can be retrofitted and converted to narrower pitches at short notice. For this purpose, the support profiles are prepared with evenly spaced holes along their entire length. This cost-effective solution is ideal for beginners who handle changing transport goods. In addition to the choice of Roller density play diameter and bridge feet plays an important role. This is because, in addition to the castors, the substructure must also carry the load that is moved via the castors.

A solution for lattice boxes and steel boxes with small feet is offered with the Varioflex„ roller conveyor series“ offered. Rollers with extra-thick walls and narrow roller pitches allow for the smallest support surfaces. Motor power and drive chains are also used. In addition to the drive rollers, light barriers often ensure the exact positioning of the conveyed goods.

If pallets are to be loaded or unloaded, a station for pallet trucks is ideal for this task. The neuralgic joint, namely the connection of two roller conveyors, is elegantly solved at HaRo with a special chain wheel with corresponding chain guide while maintaining the close spacing of the rollers.

Curved roller conveyors as a flexible solution

Rolling straight ahead is easy. But what if you want to go round a corner? That's where Roller conveyor curves. Quick and precise steering with or without drive and in almost any angle and any desired direction. Various drive types such as belt-driven drive, double chain drive or tangential chain drive with side bow chain ensure that all idlers start up evenly.

Roller conveyors with split cylindrical idlers or roller conveyor curves are also used in curves. A speciality are Slide-on elements made of polyamide (PA) represent. They form the basis for maintaining the exact running direction. Roller track switches allow goods to be fed in without losing time.

In addition to idlers, roller conveyors and vertical conveyors, the entire electrical and electronic systems as well as details for remote maintenance, including control technology and switch cabinet construction, are created in-house. In this way, all parts of a system are planned overall process and exact installation date brought together.

If additional devices or systems need to be integrated, interfaces are created by the software engineers. Warehouse management software also offers the opportunity to optimise the internal material flow through the Optimise the linking of production, transport, storage, order picking, packaging and sales.