Helmers Maschinenbau GmbH presents at IFFA 2025 will focus on crate folding stations for pooling systems, tube conveyors and cutting technology as well as end-of-line automation solutions and robotics.

The Onsnabrück-based company does not supply standard products, but develops customised complete solutions for the flow of materials and goods that are tailored to individual customer requirements. These ensure optimised processes and can also be integrated into existing infrastructures.

Crate folding stations for pooling systems

Pooling systems - i.e. reusable logistics systems consisting of standardised transport containers, pallets or crates that are reused - are playing an increasingly important role in the modern food industry. At IFFA, Helmers will be presenting its crate folding stations, which have been specially developed for use in such systems. They are modular structure and can be customised to the individual requirements of companies. Special features of the low-maintenance crate folding stations from Helmers are their high process reliability and energy efficiency. Their hygienic design contributes to increased safety in companies in the food industry.

Pipe conveyors and dismantling technology

Helmers offers fully and semi-automated tube conveyors as well as customised slaughtering and cutting lines for companies in the meat industry. The robust and durable systems are tailored to the special requirements of meat processing. Optionally, they can be combined with powerful MES systems. Data on the status of production processes and the achievement of your production targets can be called up in real time.

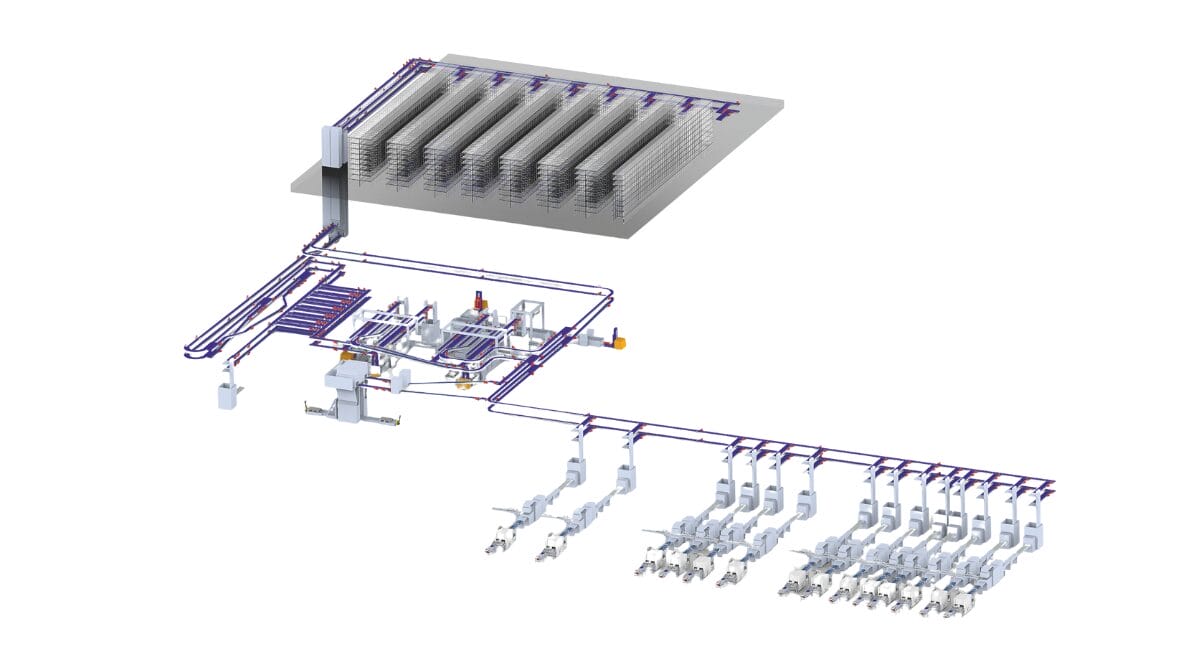

End-of-line automation and robotics

Automated systems and robotics at the end of a production line make packaging, palletising, sorting and shipping processes more efficient. To this end, Helmers develops high-performance Solutions that decouple production from shipping. The systems reduce manual processes and optimise warehouse and transport logistics. The automation solutions are designed to operate 24 hours a day, seven days a week. They take over the any combination of mixed pallets and can also carry out just-in-time order fulfilment. With flexible robotics concepts, they can be customised to individual requirements. Robotics technology relieves employees of physically demanding tasks and ensures precise and reliable production control.

„The automation and digitalisation of intralogistics is no longer just an option, but a necessity for the vast majority of companies in order to remain competitive. Our customers benefit from customised solutions that not only increase their efficiency, but also represent sustainable and future-proof investments. With our full-service approach, we support companies on their way to a digitalised and automated future.“

hristian Sening, Sales Manager at Helmers Maschinenbau

Source: Helmers Mechanical Engineering

Helmers Maschinenbau at the IFFA 2025: Hall 12.0, Stand C69