In a joint project with R-Cycle, an open platform for the use of digital product passports, and the Korozo Group, a processor of flexible packaging, Henkel wants to test how the digital product passport works in practice and what advantages it offers the industry.

The pressure to develop environmentally friendly and resource-efficient packaging has increased noticeably. At the same time, global supply chains require greater transparency along the entire value chain in order to make the origin of materials, their processing and the end of their life cycle traceable.

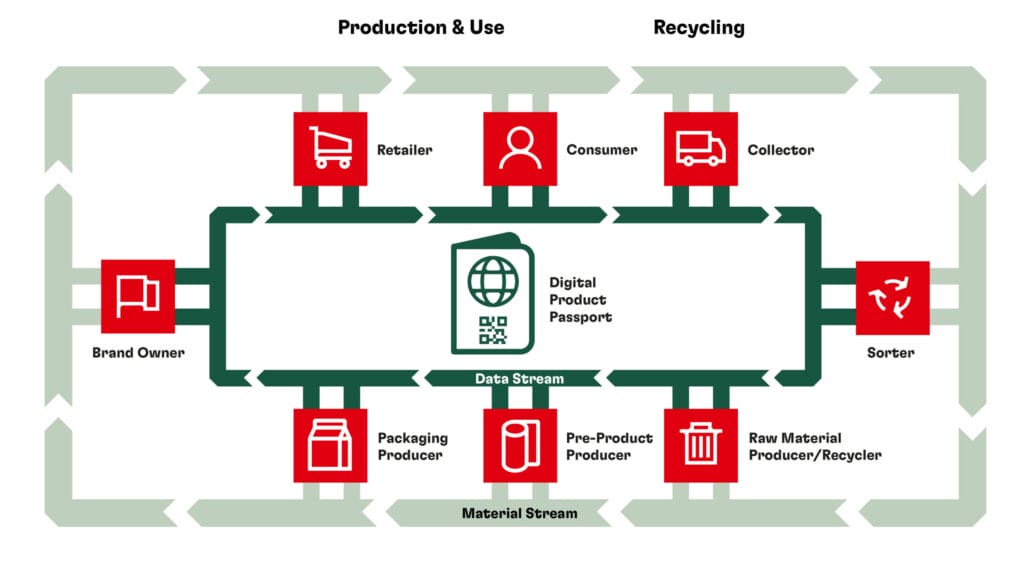

Against this backdrop, the Digital Product Passport (DPP) is taking centre stage. It is a key tool for digitally recording and making accessible the necessary information on the composition, life cycle and sustainability aspects of a product. Driven by regulatory requirements such as the Ecodesign for Sustainable Products Regulation (ESPR) of the European Union, the DPP will be mandatory in many industries from 2027 become.

The digital data record contains information such as the material composition, technical specifications and recyclability of a product. Each product is given a unique identification, often via QR codes or RFID tags, which enable simple traceability along the value chain. The quality of the data collected is crucial for this. Companies along the value chain must provide relevant information that is prepared in a standardised format and accessible to all stakeholders.

Adhesive under the magnifying glass

Henkel has decided to actively test and implement the DPP. The test is being carried out together with the Korozo Group, a processor of flexible packaging, and R-Cycle, an open standards-based platform for the use of digital product passports to ensure the traceability of packaging. The system developed by Henkel Solvent-free adhesive Loctite Liofol is used for the reliable lamination of stand-up pouches. It is characterised by its chemical and thermal resistance and is therefore suitable for aggressive filling goods, pasteurisation and high-speed packaging lines with high sealing temperatures.

This example, which was tested with an end product from Henkel Consumer Brands, shows what the DPP looks like in practice. Every packaging produced with Loctite Liofol is labelled with a QR code that is linked to the R-Cycle DPP. This means that technical data, safety information and environmental aspects can be called up directly. Henkel is working with R-Cycle to extend this traceability and thus also optimise the disposal and recyclability of the product.

„Henkel's application shows very well how relevant information on the packaging components used - in this case the adhesive - can be recorded in the DPP and made available throughout the entire product life cycle. This enables us to create defined transparency and simple traceability along the value chain. We see this as a decisive advantage with regard to the constantly growing need for information.“

Dr Benedikt Brenken, Head of R-Cycle

In the DPP, Henkel also records the Carbon emissions generated during the production and use of the laminating adhesive. This information is crucial for the fulfilment of ESPR requirements and for the assessment of the product's carbon footprint throughout its life cycle.

The information recorded in the DPP enables companies at the end of the life cycle to properly dispose of packaging on arrival at the sorting and recycling centres and thus make a positive contribution to the circular economy and recycling rates.

„We are well on the way to being able to offer every customer a sustainable product that either comes from sustainable sources or has an excellent recycling profile. As a supplier and brand owner, we are able to cover a large part of the value chain. 80 per cent of a product's environmental footprint is determined at the design stage. We use our knowledge to advise our customers at an early stage.“

Philippe Blank, Head of Circular Economy at Henkel

DPP as a driver of innovation and sustainability

„We see the DPP as a great opportunity to promote the circular economy through better recycling information, increase transparency in the supply chain and strengthen the trust of our customers and partners in our products,“ summarises Philippe Blank. In the coming years the DPP will play a central role in the packaging industry. as an important lever for innovation and increasing competitiveness. In addition to sustainable product development, the DPP makes it possible to develop new business models based on digitalisation and the circular economy.

Source: Handle