At ACHEMA 2018 in Frankfurt, labelling specialist HERMA is showcasing three new tamper-evident modules to demonstrate how machine manufacturers can equip their packaging systems very efficiently and also handle large quantities.

On display at the trade fair are three different Tamper-evident labelling modules"We are presenting a solution for speeds of up to around 40 metres per minute, a solution for higher speeds with motorised components, e.g. for winding and unwinding, and a solution for particularly tight spaces," explains Raffaele AltilioHead of Key Account Management HERMA labelling machines.

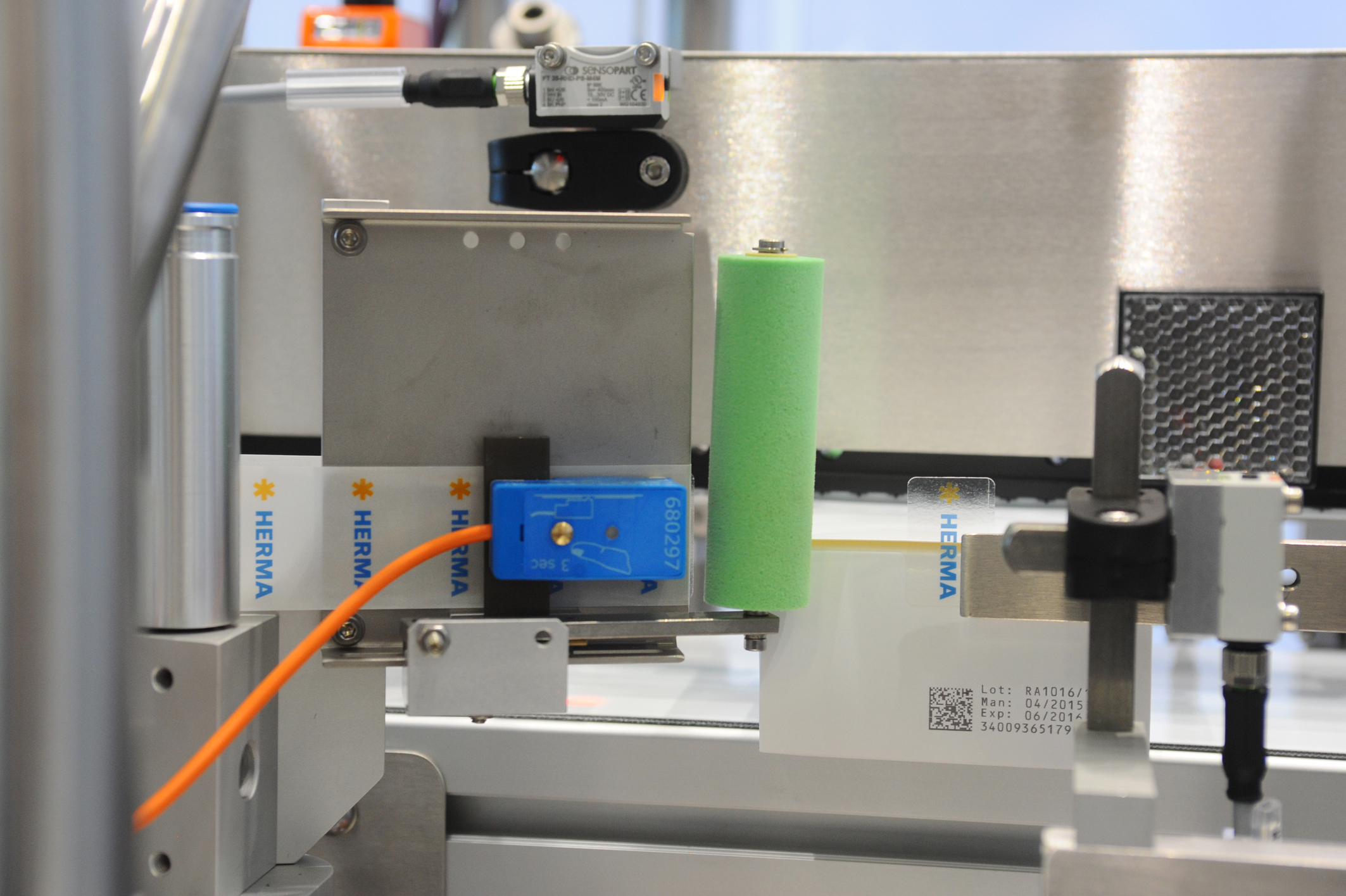

All three solutions each include two HERMA 400 high-performance labellers, which can be arranged in such a way that they can be used for all standard positioning of Tamper-evident labels on the side flaps of folding boxes. Due to its compact size, the HERMA 400 is particularly suitable for installation in packaging lines: HERMA was the first supplier to succeed in integrating the control system within the labeller in series production, making a separate control cabinet superfluous. "HERMA has thus set a global standard and now has by far the most experience in this field," says Altilio.

Several thousand labellers per year

In addition to compactness and high performance, this is an important advantage of the HERMA 400 and thus of the tamper-evident modules: They are manufactured at HERMA in large quantities on a synchronised assembly line. In the case of the HERMA 400, this now amounts to several thousand units per year. "This is probably unique in the world. This is accompanied by a high degree of Process reliability in the production of the labellers themselves, but of course also with regard to the processes at the pharmaceutical manufacturer or system integrator," says Martin Kühl, who heads the HERMA Labelling Machines division. "The tamper-evident modules utilise the same standard HERMA 400 components that are also used for other tasks and industries. With our modular design, it is possible to achieve customised production 'off the peg', so to speak. This allows us to respond very specifically to the individual needs of individual plant manufacturers."

HERMA at the ACHEMA 2018: Hall 3.1, Stand F57